Polyether ether ketone-based artificial bone composite material and preparation method thereof

A technology of polyether ether ketone and composite materials, which is applied in the direction of pharmaceutical formulations, prostheses, coatings, etc., can solve the problems of poor mechanical properties and wear resistance, and cannot be used as artificial bone materials, so as to improve interface adhesion, Improved agglomeration and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Weigh 10 grams of dry hydroxyapatite powder into a reaction bottle, add 40ml of absolute ethanol and 40ml of deionized water to the bottle, then slowly add 1ml of coupling agent KH550, and keep it at room temperature under nitrogen protection Stir for 20 minutes. Then reflux for 4.5 hours. After reflux, use a sand core funnel and an organic filter to filter, wash repeatedly with absolute ethanol, place in an oven at 80°C for drying treatment, take it out and grind it into a fine powder to obtain modified hydroxyapatite powder.

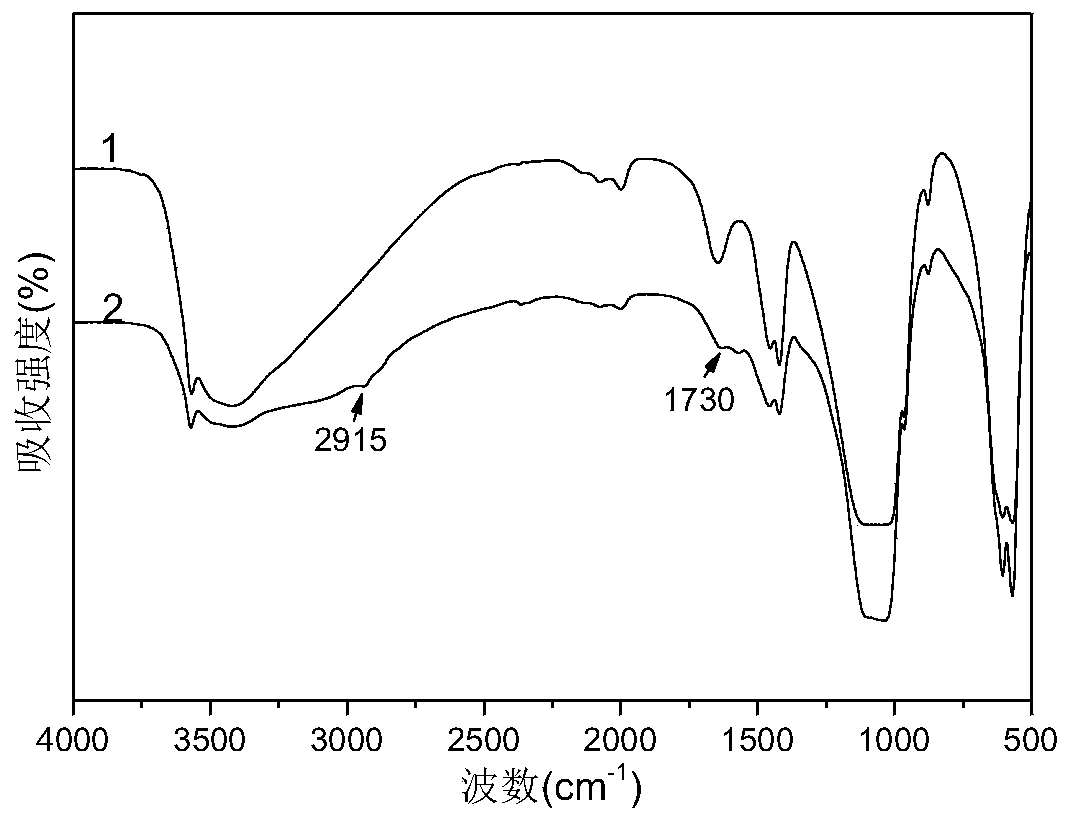

[0031] figure 1 The infrared spectrograms of the modified hydroxyapatite and hydroxyapatite prepared in Example 1 above are given. Among them, curve 1 is hydroxyapatite, and curve 2 is modified hydroxyapatite. It can be seen that in curve 2, 1730cm -1 The absorption peak of carbon-hydrogen bond appears at 2915cm -1 The absorption peaks of methyl and methylene appear at the place, because the product has been washed many times with a...

Embodiment 2

[0036] Weigh 0.3 g of sulfonated polyether ether ketone into a sample bottle, add 2.5 ml of dimethyl sulfoxide to fully dissolve the sulfonated polyether ether ketone, then add 0.15 g of modified hydroxyapatite powder, and stir at room temperature After 4-6 hours, put it into an ultrasonic machine for ultrasonication for 1-2 hours to make it fully mixed.

[0037] Place the surface-treated polyether ether ketone plate in a horizontal oven, and pour the evenly stirred mixture on the polyether ether ketone plate through a filter cloth by laying a film, set the oven to 80-120°C, and Dry for 12 hours to obtain a sulfonated polyether ether ketone / modified hydroxyapatite / polyether ether ketone composite material.

Embodiment 3

[0039] 0.3 g of sulfonated polyether ether ketone was weighed and placed in a sample bottle, and 2.5 ml of dimethyl sulfoxide was added to fully dissolve the sulfonated polyether ether ketone. Then add 0.3 g of modified hydroxyapatite powder, stir at room temperature for 4-6 hours, and then put it into an ultrasonic instrument for 1-2 hours to make it fully mixed.

[0040]Place the surface-treated polyether ether ketone plate in a horizontal oven, and pour the evenly stirred mixture on the polyether ether ketone plate through a filter cloth by laying a film, set the oven to 80-120°C, and Dry for 12 hours to obtain a sulfonated polyether ether ketone / modified hydroxyapatite / polyether ether ketone composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com