Device for photocatalytic degradation of organic waste gas and application method thereof

A technology of organic waste gas and photocatalysis, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of insufficient photocatalytic reaction and short residence time, so as to prolong residence time, realize purification treatment and promote decomposition efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

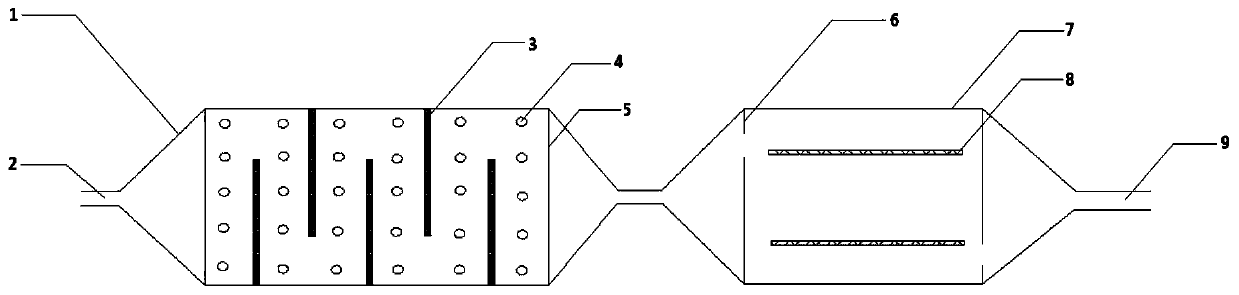

[0065] Such as figure 1 A device for photocatalytically degrading organic waste gas is shown, comprising a primary catalytic box 1 and a secondary catalytic box 7; the primary catalytic box 1 and the secondary catalytic box 7 are through-connected, and the The primary catalytic case 1 and the secondary catalytic case 7 are sealed structural parts;

[0066] One end of the primary catalytic box 1 is provided with a first air inlet 2 for inputting organic waste gas into the primary catalytic box 1;

[0067] The other end of the first-stage catalytic box 1 is provided with a first air outlet, which is used to make the organic waste gas passing through the first-stage catalytic box 1 exit the first-stage catalytic box 1 and enter the second-stage

[0068] Catalytic box: filter screens 5 are respectively arranged at both ends of the inner chamber of the primary catalytic box 1 .

[0069] One end of the secondary catalytic box 7 is provided with a second air inlet, and the first ai...

Embodiment 2

[0073] Utilize the device described in embodiment 1 to carry out photocatalytic degradation xylene gas experiment

[0074] The photocatalyst is made of titanium dioxide and silica sol dissolved in a mixed solution of water and ethanol (2:1) with a specific gravity of 4:1, stirred at a speed of 4000r / min for 60min, and then ultrasonically treated for 30min to form a uniform temperature solution , a photocatalyst supported on nickel foam.

[0075] The co-catalyst is made of manganese carbonate into a solution with a certain concentration, let the molecular sieve stand in the solution for 30 minutes, and after taking it out, calcinate it in a tube furnace at 400°C for 1 hour.

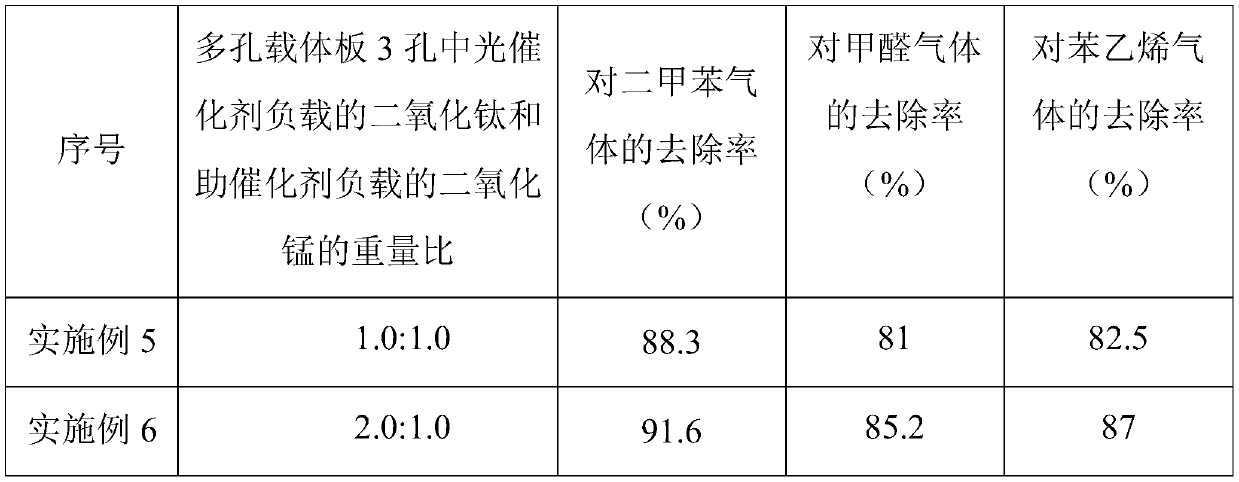

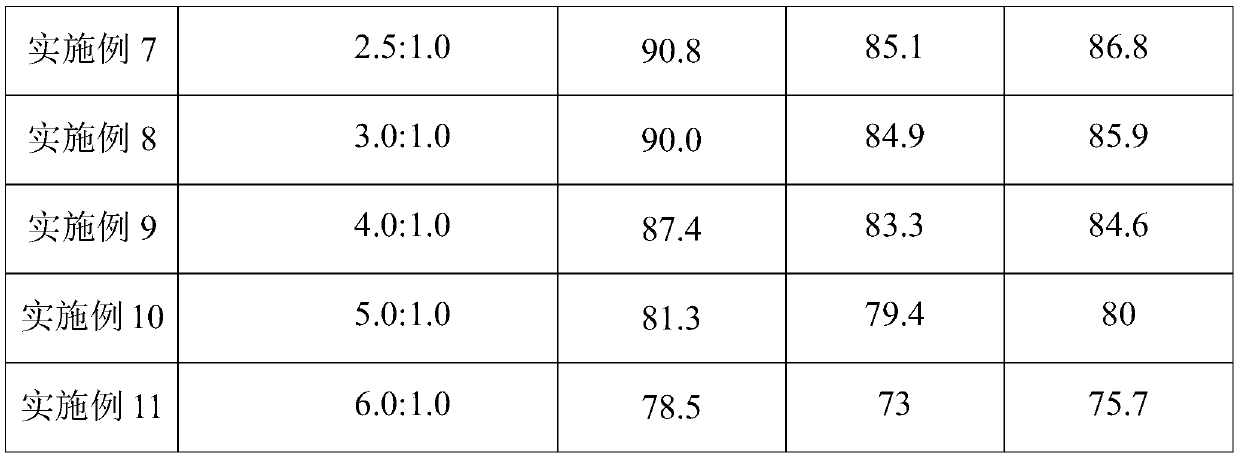

[0076] Step 1, photocatalyst and cocatalyst are placed in the hole of porous carrier plate 3, cocatalyst is placed in adsorption bed 8, wherein the weight ratio of the titanium dioxide of photocatalyst load and the manganese dioxide of cocatalyst load in porous carrier plate 3 holes are: 3:1, the loading ...

Embodiment 3

[0082] Utilize the device described in embodiment 1 to carry out photocatalytic degradation xylene gas experiment

[0083] The photocatalyst is made of titanium dioxide and silica sol dissolved in a mixed solution of water and ethanol (2:1) with a specific gravity of 1:1, stirred at a speed of 4000r / min for 60min, and then ultrasonically treated for 30min to form a uniform temperature solution , a photocatalyst supported on honeycomb aluminum.

[0084]The co-catalyst is obtained by making a solution with a certain concentration of manganese carbonate, letting the cordierite stand in the solution for 30 minutes, taking it out and calcining it in a tube furnace at 400°C for 1 hour.

[0085] Step 1, photocatalyst and cocatalyst are placed in the hole of porous carrier plate 3, cocatalyst is placed in adsorption bed 8, wherein the weight ratio of the titanium dioxide of photocatalyst load and the manganese dioxide of cocatalyst load in porous carrier plate 3 holes are: 3:1, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com