Rectification device and method for extracting high-purity mesitylene product from oil generated by trimethylbenzene isomerization reaction

A technology of mesitylene and mesitylene, applied in the field of energy-saving combined production equipment, which can solve the problems of poor technical economy, small relative volatility difference, equipment construction cost, high production energy consumption cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

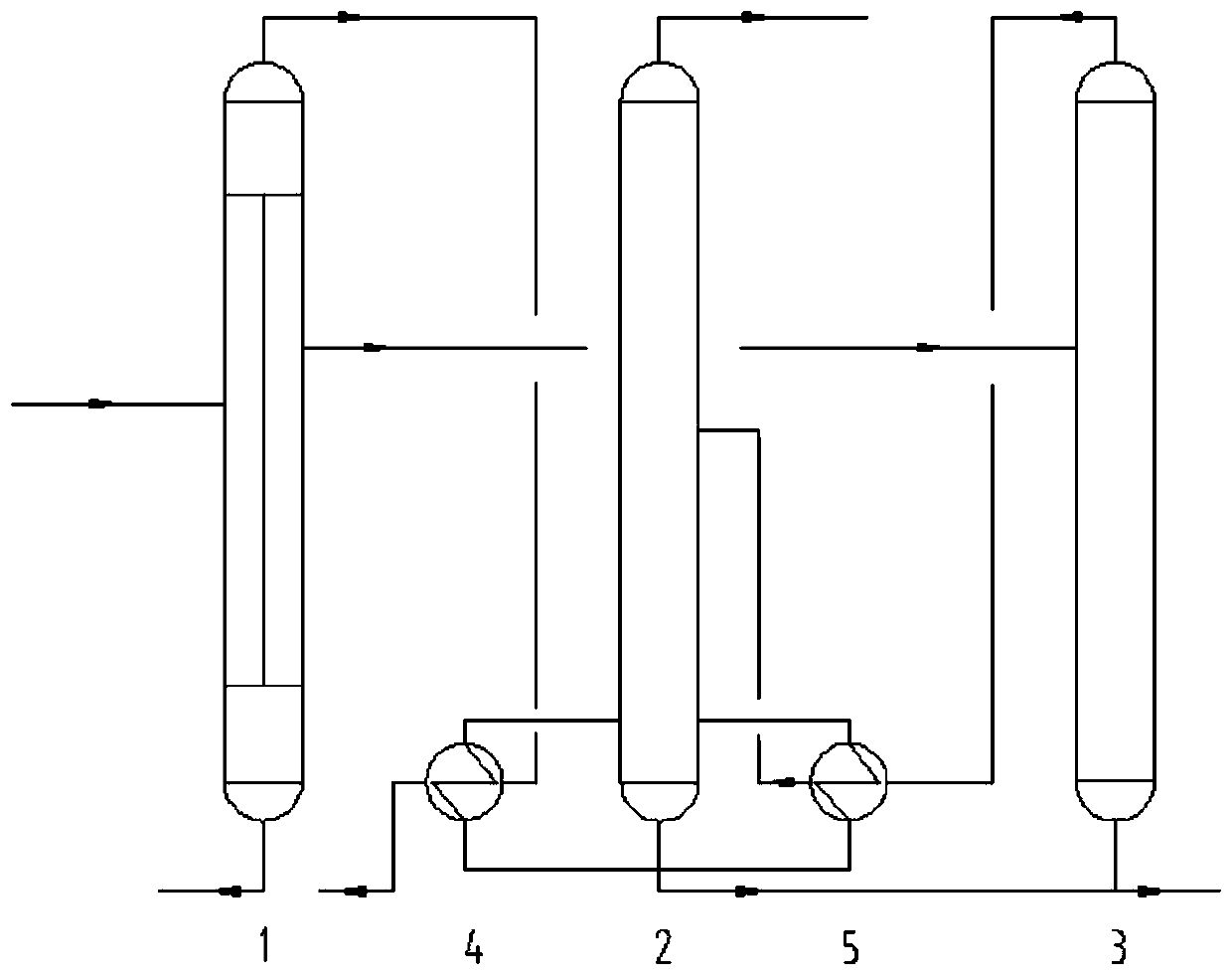

[0032] A certain device adopts trimethylbenzene isomerization reaction to generate oil to purify mesitylene products with a purity greater than 98.5%, and by-product high-purity mesitylene products with a purity greater than 99.%. The device is mainly composed of a lightening rectification tower 1, a concentration rectification tower 3, a product purification rectification tower 2, and a condensation reboiler;

[0033] The process flow is that the oil produced by the isomerization reaction of trimethylbenzene enters the light removal and rectification tower 1 from the feed side of the partition wall, and controls the gauge pressure at the top of the tower at 0.01MPa by controlling the flow rate of the reflux tank after condensation at the top of the tower, and all the oil and gas at the high temperature at the top of the tower enter The bottom product of the mesitylene product rectification tower 2 is the rectification tower A condensing / reboiler 4 as a heat source, the light i...

Embodiment 2

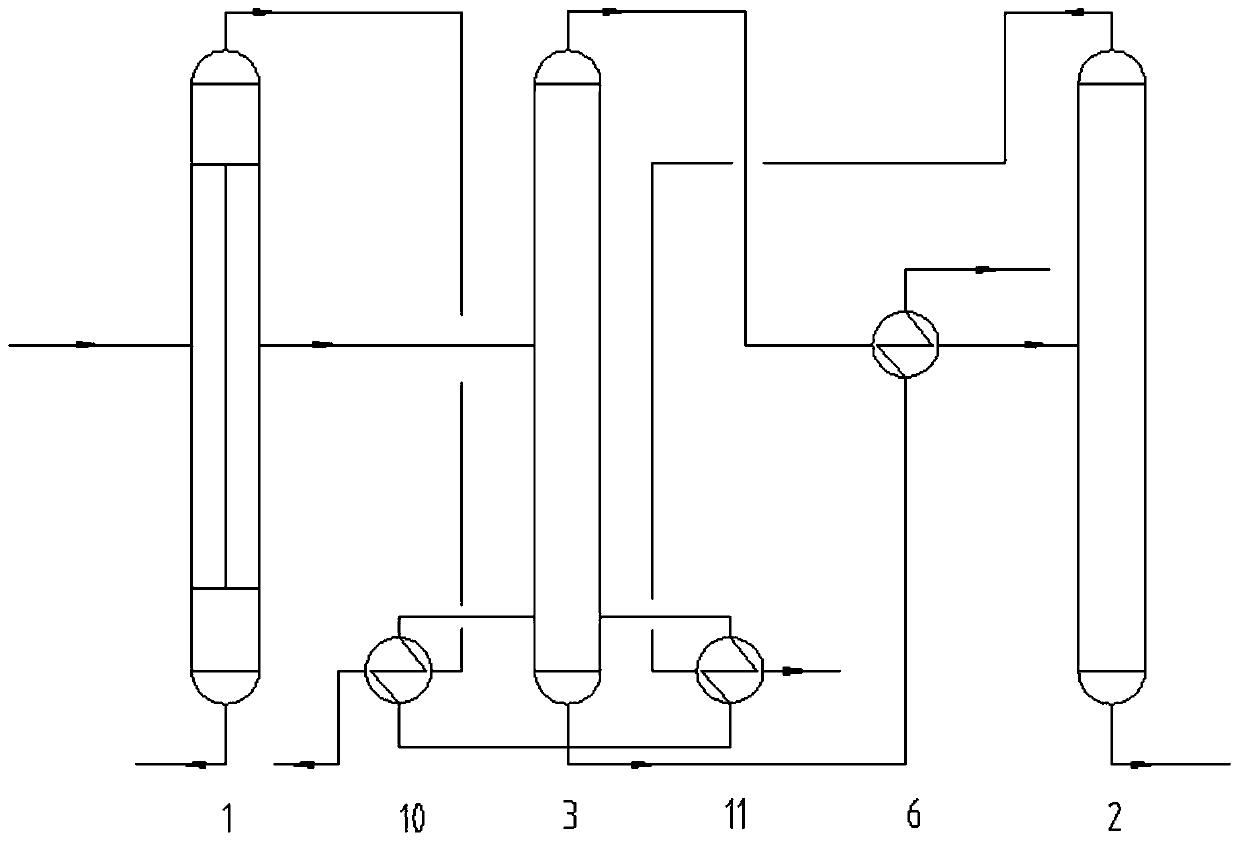

[0036] A device uses trimethylbenzene isomerization to extract mesitylene products with a purity greater than 98.5%. It is mainly composed of a lightening rectification tower 1, a product rectification tower 2, an enrichment rectification tower 3, and a condensing reboiler;

[0037] The process flow is that the oil produced by the isomerization reaction of trimethylbenzene enters the delightening rectification tower 1 from the feed side of the partition wall, and controls the gauge pressure at the top of the tower at 0.25MPa by controlling the flow rate of the reflux tank after condensation at the top of the tower, and all the oil and gas at the high temperature at the top of the tower enter Condensation and rectification tower A condensing / reboiler 10 is used as a heat source at the bottom of the enrichment rectification tower 3, and the light impurity component oil with a mesitylene content of less than 2.5% is extracted from the top of the tower, and the trimethylbenzene con...

Embodiment 3

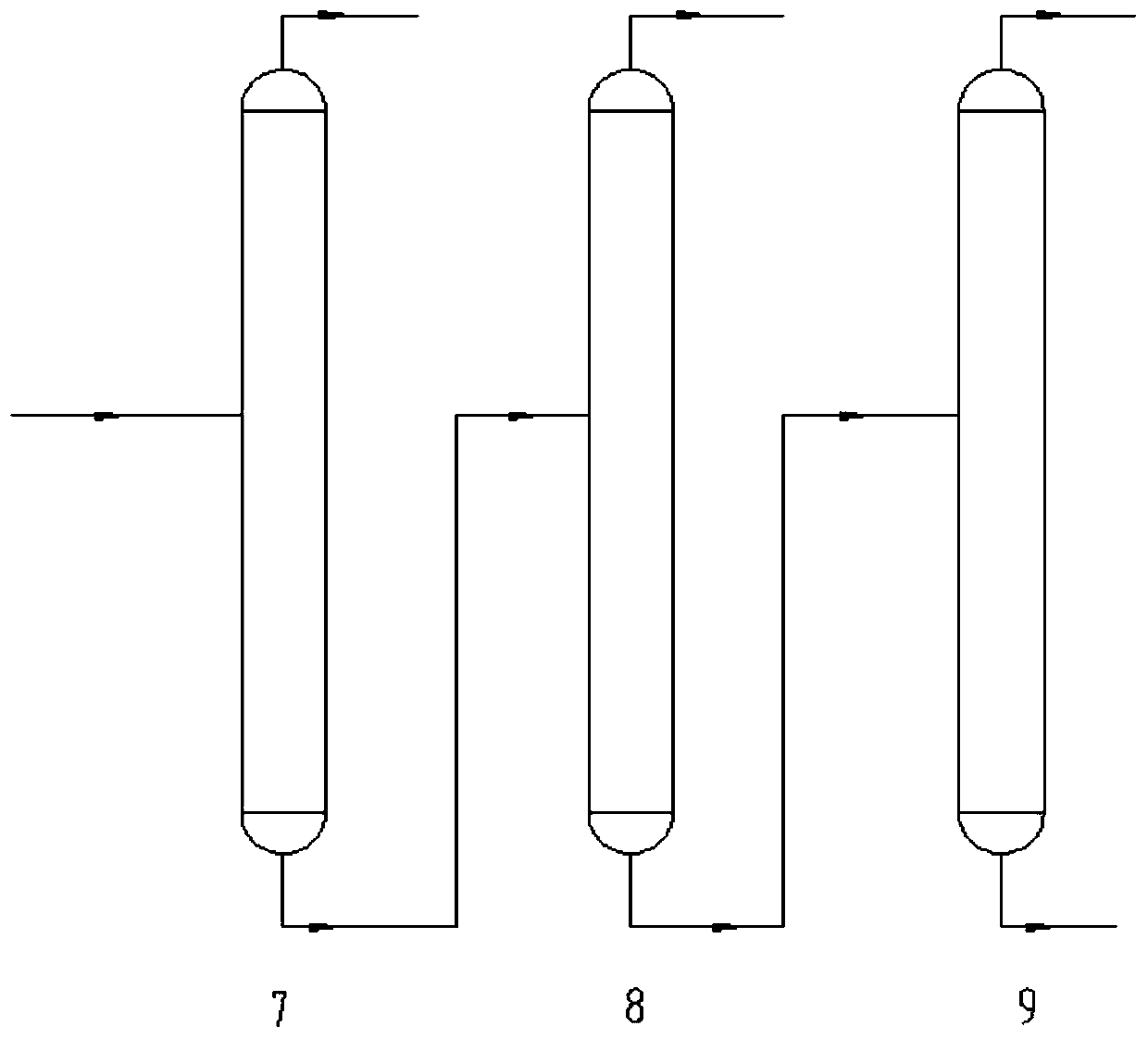

[0040] A mesitylene product manufacturer uses mesitylene isomerization reaction to generate oil with a purity of more than 98.5%. In terms of technology, the light-removing rectification tower 1 adopts the positive pressure operation of the dividing wall tower, the enrichment rectification tower 3 is operated under positive pressure, and the product rectification tower 2 is operated under reduced pressure. The bottom condensing / reboiler heat source for heat integration. The specific implementation process is as follows:

[0041] The oil produced by the isomerization reaction of trimethylbenzene enters the light removal rectification tower 1 from the 35 plates on the feed side of the partition wall. There are 30 theoretical plates in the rectification section of the tower, 60 theoretical plates on both sides of the partition wall, and 30 theoretical plates in the stripping section. The gauge pressure at the top of the tower is controlled at 0.08 to 0.10 MPa by controlling the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com