Ultra-microporous zirconium-based metal organic framework material as well as preparation method and application thereof

An organic framework and metal-based technology, applied in the field of preparation of ultra-microporous zirconium-based metal-organic framework materials, can solve problems such as poor stability, incompatible selectivity, and high adsorption capacity, and achieve weakened acidity, increased adsorption capacity, and increased selectivity. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

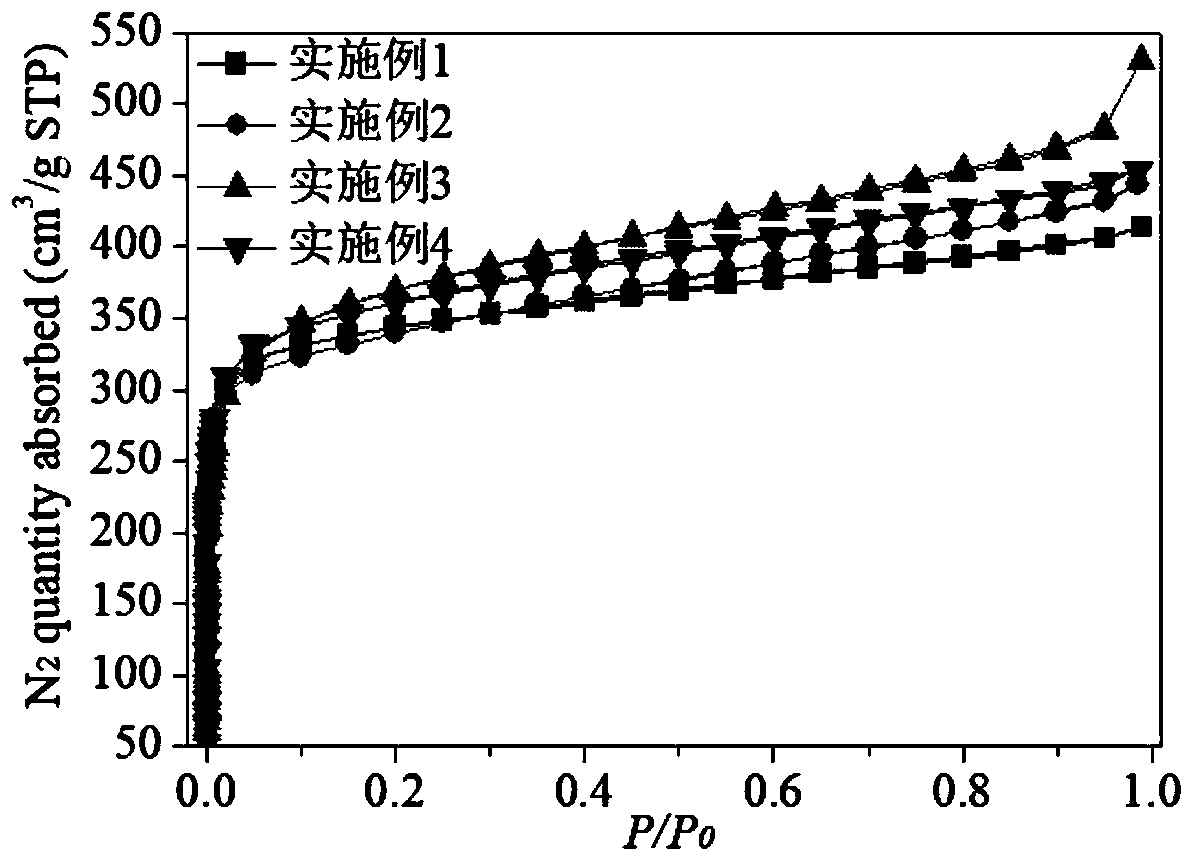

Embodiment 1

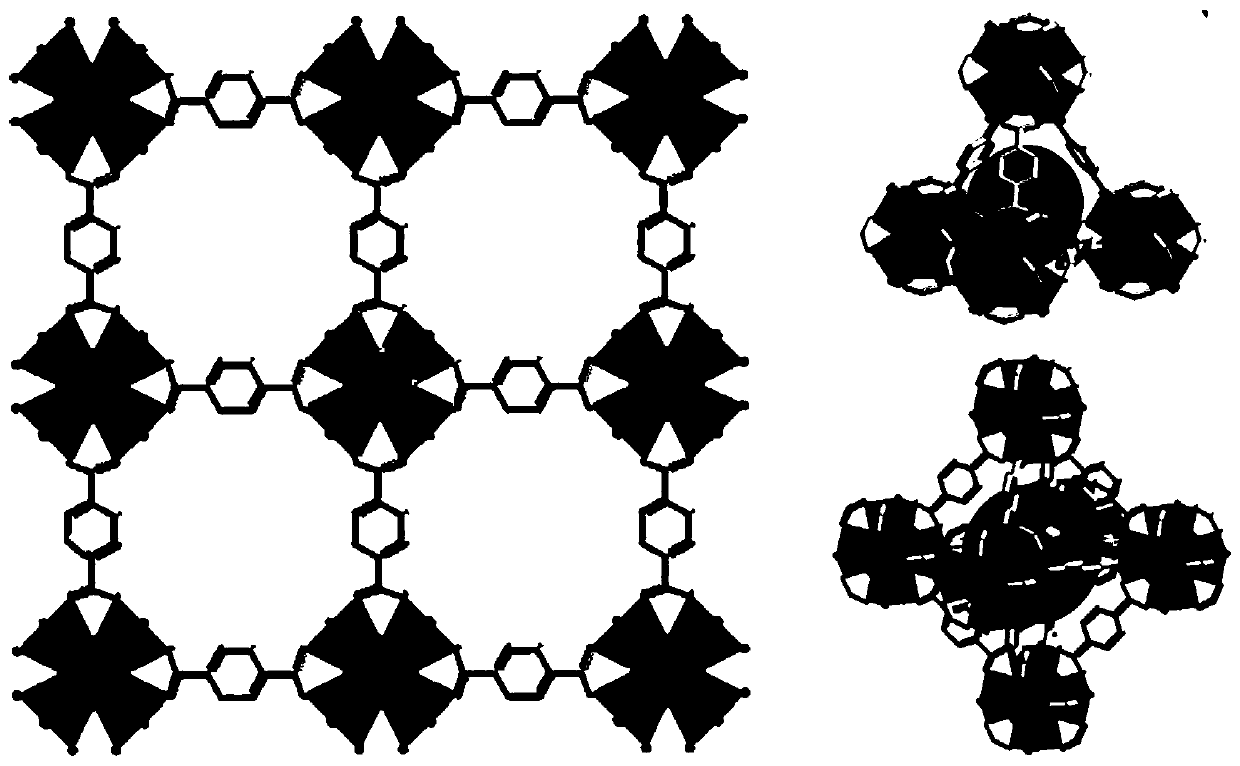

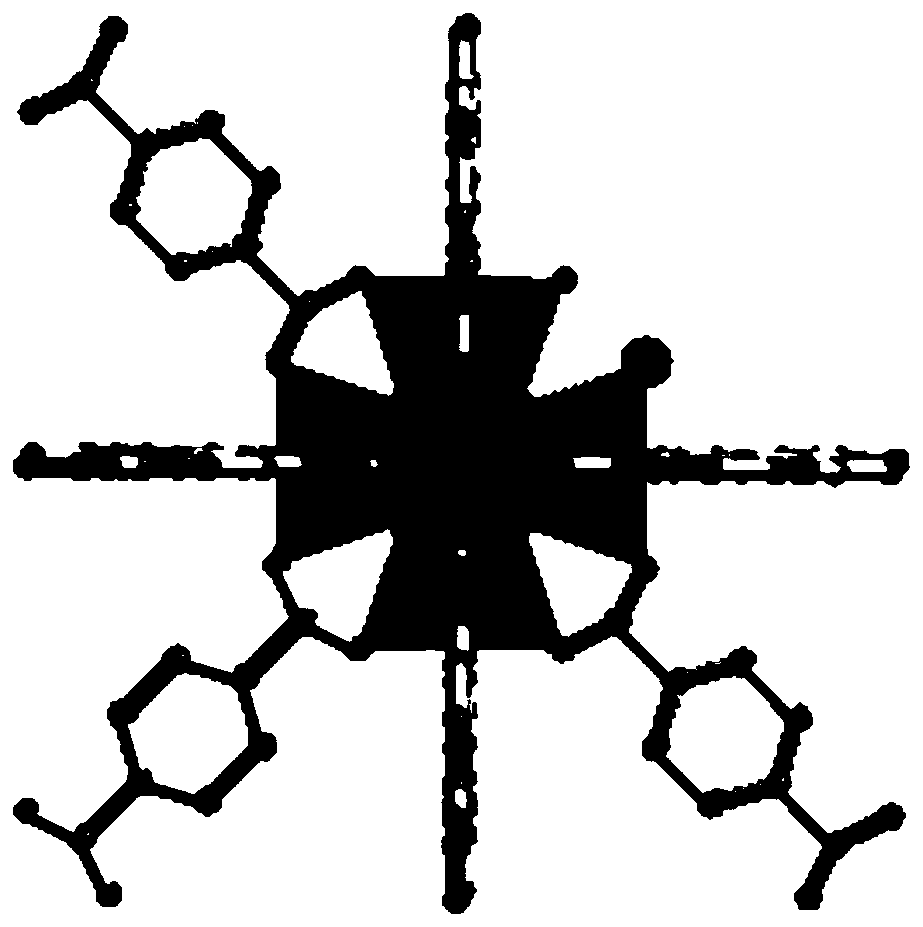

[0029] Example 1: Preparation of zirconium-based MOFs material

[0030] Add the precursor zirconium chloride to 60mL DMF, 10mL acetic acid and the precursor terephthalic acid in an equimolar amount to the zirconium chloride, continue to stir at room temperature for 30min, then transfer to a 100mL reaction kettle, and place it in a programmed incubator, 120 React at ℃ for 24 hours, then wash with DMF and ethanol for 3-4 times respectively, set the centrifugation speed at 4000-6000r / min, set the centrifugation time at 10-15min, and then dry it.

Embodiment 2

[0031] Embodiment 2: Preparation of zirconium-based MOFs material

[0032] The precursor zirconium chloride and basic N-pyrazine molecules were dissolved in 60mL organic solvent DMF at a mass ratio of 100:3.0, and ultrasonically dissolved for 10 minutes to obtain a mixed solution, which was microwaved at 100°C for 10 minutes. The reaction temperature was 100°C; After the reaction is over, add 60mL DMF, 10mL acetic acid and the precursor terephthalic acid in an equimolar amount to zirconium chloride, continue to stir at room temperature for 30min, then transfer to a 100mL reactor and place it in a temperature-programmed oven , reacted at 120°C for 24 hours, then washed with DMF and ethanol for 3-4 times respectively, the centrifugal speed was set at 4000-6000r / min, the centrifugal time was set at 10-15min, and then dried.

Embodiment 3

[0033] Embodiment 3: Preparation of zirconium-based MOFs material

[0034] The precursor zirconium chloride and basic N-pyrazine molecules were dissolved in 60mL of organic solvent DMF at a mass ratio of 100:5.0, and ultrasonically dissolved for 10 minutes to obtain a mixed solution, which was microwaved at 100°C for 10 minutes. The reaction temperature was 100°C; After the reaction is over, add 60mL DMF, 10mL acetic acid and the precursor terephthalic acid in an equimolar amount to zirconium chloride, continue to stir at room temperature for 30min, then transfer to a 100mL reactor and place it in a temperature-programmed oven , reacted at 120°C for 24 hours, then washed with DMF and ethanol for 3-4 times respectively, the centrifugal speed was set at 4000-6000r / min, the centrifugal time was set at 10-15min, and then dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com