Blocking remover based on deep eutectic solvent and preparation method thereof

A technology of deep eutectic solvent and plugging agent, which is applied in chemical instruments and methods, drilling compositions, bulk chemical production, etc., and can solve the problem of limited application of chelation descaling technology and poor removal effect of strontium barium sulfate scale , high cost of chelating agents, and achieve the effects of improving plugging removal efficiency, facilitating large-scale production, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

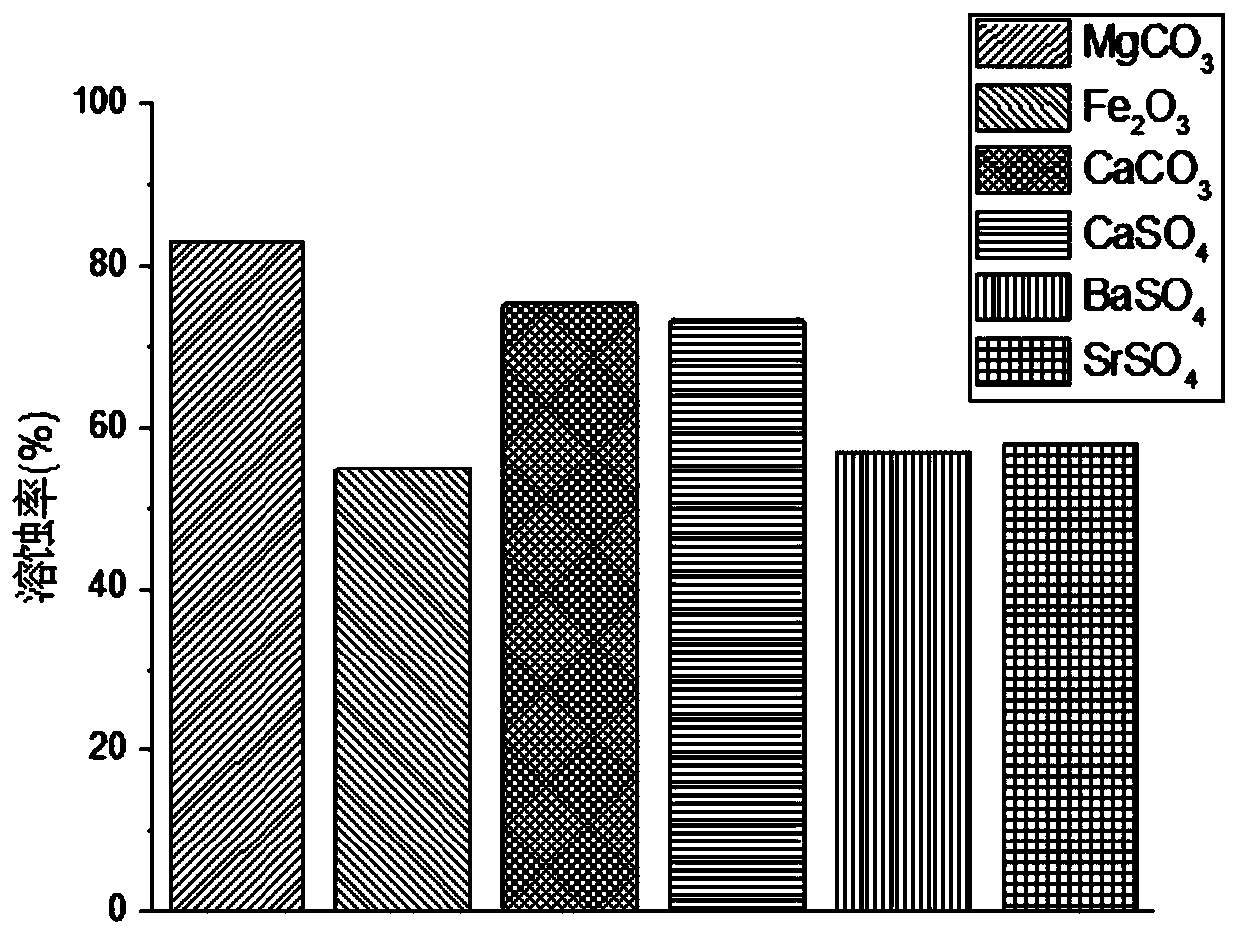

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method based on a novel plug-removing agent of a deep eutectic solvent, comprising the following process steps:

[0025] (1) Design and synthesis of deep eutectic solvent-based plugging remover

[0026] Weigh ammonium chloride and choline chloride (ammonium chloride: choline chloride = 1:1, molar ratio) as hydrogen bond acceptors (HBA); polyaspartic acid (11-13 parts), ethylene dichloride Amine tetramethylene phosphonic acid (5~7 parts), amino trimethylene phosphonic acid (5~7 parts), diglycolamine (2~4 parts), tris(hydroxymethyl)methylglycine (2~3 parts ), glycerin (2-4 parts), trehalose (2-3 parts), and caffeic acid (1-2 parts) are mixed according to the molar ratio to form a hydrogen bond donor (HBD); the hydrogen bond acceptor and the hydrogen bond donor According to a certain ratio (total moles of HBA:total moles of HBD = 1:0.2~10) mixed in a round bottom flask, heated in an oil bath at a temperature of 50~60°C, after the mixture forms a transparent ...

Embodiment 1

[0031] A preparation method based on a novel plug-removing agent of a deep eutectic solvent, comprising the following process steps:

[0032] (1) Design and synthesis of deep eutectic solvent-based plugging remover

[0033] Weigh ammonium chloride and choline chloride (ammonium chloride:choline chloride=1:1, molar ratio) as hydrogen bond acceptors (HBA); polyaspartic acid (11 parts), ethylenediaminetetra Methylenephosphonic acid (5 parts), aminotrimethylene phosphonic acid (5 parts), diglycolamine (2 parts), tris(hydroxymethyl)methylglycine (2 parts), glycerin (2 parts), trehalose (2 parts), caffeic acid (1 part) are mixed as hydrogen bond donor (HBD) according to molar ratio; : 0.2) mixed in a round-bottomed flask, heated in an oil bath at 50°C, after the mixture formed a transparent homogeneous liquid, continued heating and stirring for 4 hours to obtain a deep eutectic solvent-based plugging remover. The synthesized deep eutectic solvent-based plug-removing agent was vacu...

Embodiment 2

[0039] A preparation method based on a novel plug-removing agent of a deep eutectic solvent, comprising the following process steps:

[0040] (1) Design and synthesis of deep eutectic solvent-based plugging remover

[0041] Weigh ammonium chloride and choline chloride (ammonium chloride:choline chloride=1:1, molar ratio) as hydrogen bond acceptors (HBA); polyaspartic acid (13 parts), ethylenediaminetetra Methylenephosphonic acid (7 parts), aminotrimethylene phosphonic acid (7 parts), diglycolamine (4 parts), tris(hydroxymethyl)methylglycine (3 parts), glycerin (4 parts), trehalose (3 parts), caffeic acid (2 parts) are mixed as hydrogen bond donor (HBD) according to molar ratio; : 1) Mix in a round-bottomed flask, heat in an oil bath at a temperature of 50°C, and continue heating and stirring for 4 hours after the mixture forms a transparent homogeneous liquid to obtain a deep eutectic solvent-based plug-removing agent. The synthesized deep eutectic solvent-based plug-removin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com