Treatment method of oil field oil displacement agent rhamnolipid fermentation broth

A technology of rhamnolipid and fermentation liquid, which is applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of sandstone adsorption, high solid content, and influence on oil displacement effect, and achieve low surface tension and interfacial tension, good temperature resistance, good salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for reducing the adsorption of rhamnolipid fermentation broth, comprising the following steps:

[0040] The content of rhamnolipid in the rhamnolipid fermentation broth with soybean oil as carbon source is about 50g / L, and the fermentation broth is separated by a butterfly centrifuge at a speed of 6600rpm to obtain the fermentation broth and sediment;

[0041] Then use a 100nm ceramic membrane to filter the fermentation broth to obtain a filtrate and a concentrate;

[0042] The precipitate and the concentrated solution are wet ground to obtain a 10-80nm nanoscale solid mixture;

[0043] Mix the nanoscale solid mixture and the filtrate evenly, and perform low-intensity ultrasonic treatment for 15 minutes. The ultrasonic conditions are: power 200W, frequency 30KHz, and the new surfactant is obtained.

Embodiment 2

[0045] A method for reducing the adsorption of rhamnolipid fermentation broth, comprising the following steps:

[0046] The rhamnolipid content in the rhamnolipid fermentation broth using corn oil as a carbon source is about 55g / L, and the fermentation broth is separated by a butterfly centrifuge at a speed of 6600rpm to obtain the fermentation broth and sediment;

[0047] Then use a 200nm ceramic membrane to filter the fermentation broth to obtain a filtrate and a concentrated solution;

[0048] Use the nano-microbe cell disruptor to obtain the 10-80nm nano-scale solid mixture;

[0049] Mix the nano-scale solid mixture and the filtrate evenly, and perform low-intensity ultrasonic treatment for 10 minutes. The ultrasonic conditions are: power 300W, frequency 40KHz, to obtain a new type of surfactant.

Embodiment 3

[0051] A method for reducing the adsorption of rhamnolipid fermentation broth, comprising the following steps:

[0052] The content of rhamnolipid in the rhamnolipid fermentation broth with soybean oil as carbon source is about 45g / L, and the fermentation broth is separated by a butterfly centrifuge at a speed of 8000rpm to obtain the fermentation broth and sediment;

[0053] Then use a 500nm ceramic membrane to filter the fermentation broth to obtain a filtrate and a concentrated solution;

[0054] The precipitate and the concentrated solution are wet ground to obtain a 10-80nm nanoscale solid mixture;

[0055] Mix the nano-scale solid mixture and the filtrate evenly, and perform low-intensity ultrasonic treatment for 10 minutes. The ultrasonic conditions are: power 500W, frequency 50KHz, and the new surfactant is obtained.

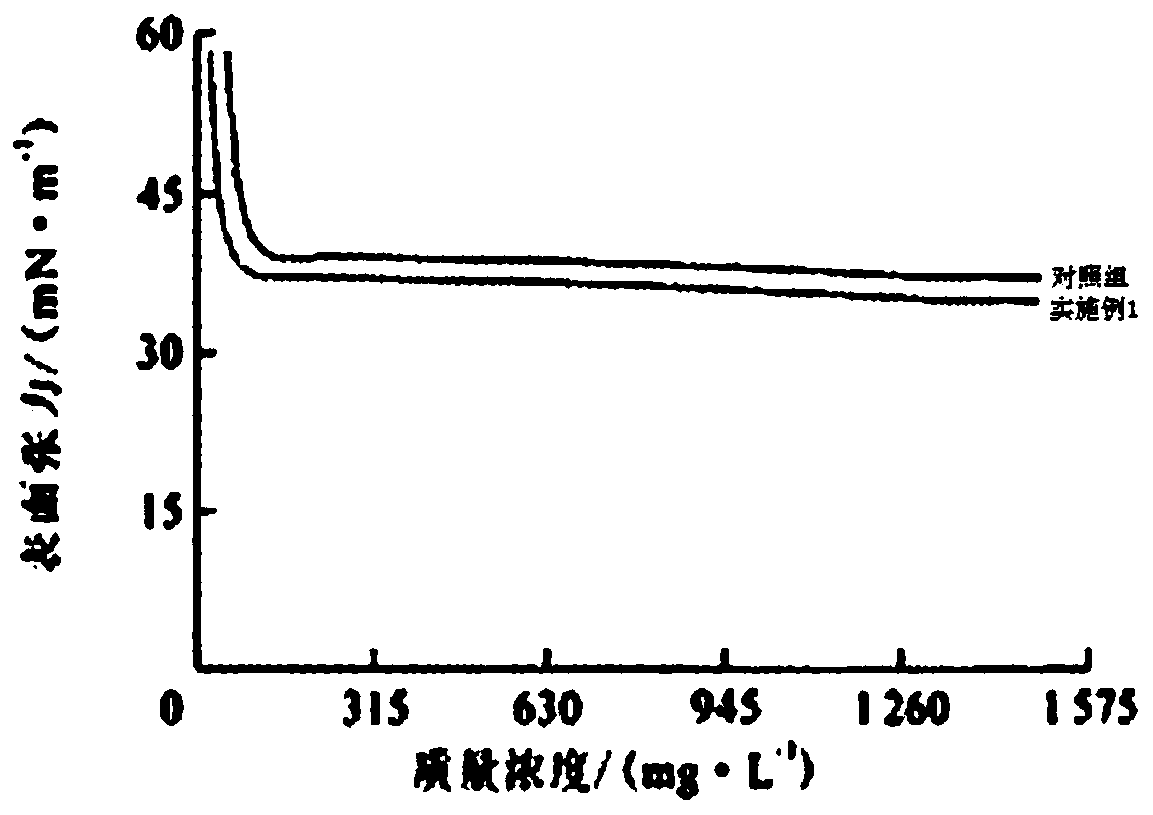

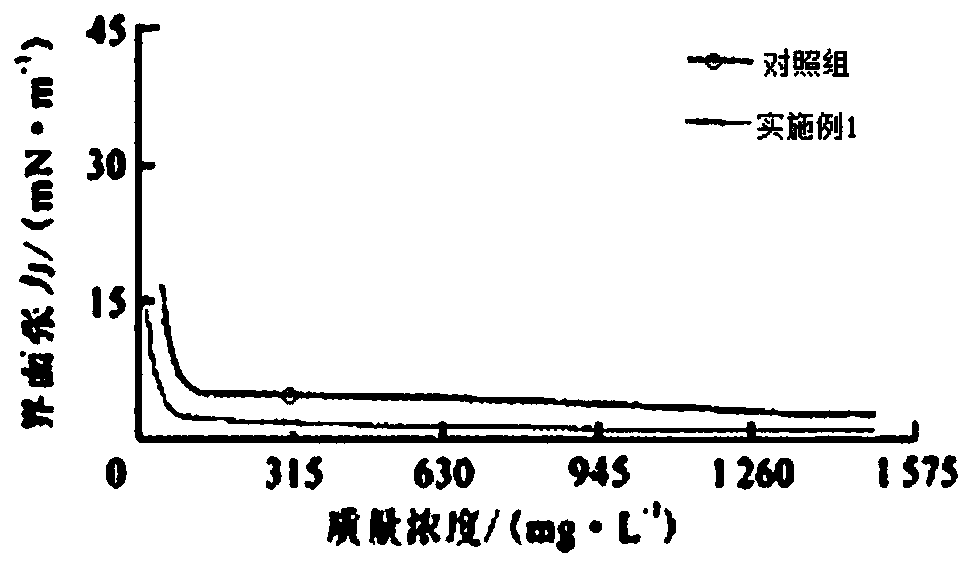

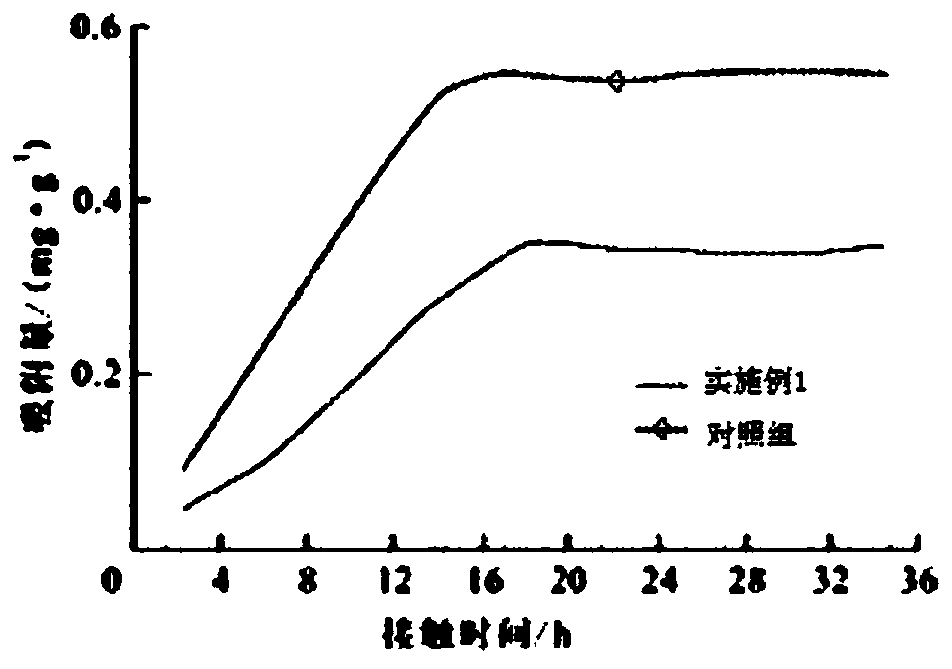

[0056] Determination of the properties of the surfactant of Example 1

[0057] Taking rhamnolipid as a measure standard, the surfactant of embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com