Recombinant escherichia coli and application thereof

A technology for recombining Escherichia coli and microbial strains, applied in bacteria, biochemical equipment and methods, microorganisms, etc., can solve problems such as industrial production of MicrocinJ25, which has not been seen before, and achieve the effect of improving the expression level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 2

[0034] Preparation Example 2 Linking the Target Fragment to the pMD18-T Vector and Transforming the Plasmid

[0035] 1. The enzyme-linked reaction system is shown in Table 3 below.

[0036] table 3

[0037] Element Dosage dd H 2 o

13.5μl 10×T4DNA Ligase Buffer 2μl pMD18-T vector 0.5μl dna 3μl T4DNA Ligase 1μl total 20μl

[0038] Mix the above components and centrifuge briefly, and place the prepared system at 16°C for overnight stability. The connected system was placed in a 4°C refrigerator for later use.

[0039] 2. Heat Shock Plasmid Transformation

[0040] a. Take out 100 μl of the prepared E. coli BL21 competent cells from the -80°C freezer, place them on ice for 10 minutes, and make them enter the 0°C competent state. In the ultra-clean bench, add 10 μl of the corresponding enzyme-ligated product (the pMD18-T vector prepared above to connect the fragment of the target gene mcjABCD) to the competent cells, ...

preparation Embodiment 3

[0047] Preparation of Example 3 double enzyme cut (BamHI and EcoR I) plasmid and expression vector pGEX-6p-1 and connection

[0048] 1. First prepare the enzyme digestion system mixture for restriction plasmid and expression vector, and then distribute it to each 0.6ml EP tube. The final enzyme digestion system (Takara Company) for each tube is shown in Table 4 below.

[0049] Table 4

[0050] Element Dosage wxya 2 o

30μl 10×Proteinase K Buffer 4μl BamHI 1μl EcoR I 1μl plasmid 4μl total 40μl

[0051] Carry out enzyme digestion in a 37°C incubator for no more than 1.5 hours, and add 2 μl of 10×Buffer to stop the enzyme digestion. The results showed that the enzyme digestion effect was good. The plasmid digested in the same step was used to recover the target fragment, and the expression vector after digestion was first placed in a 4°C refrigerator for later use.

[0052] 2. Recover the obtained target fragment an...

preparation Embodiment 4

[0059] Cultivation of Preparation Example 4 Recombinant Escherichia coli Transformant

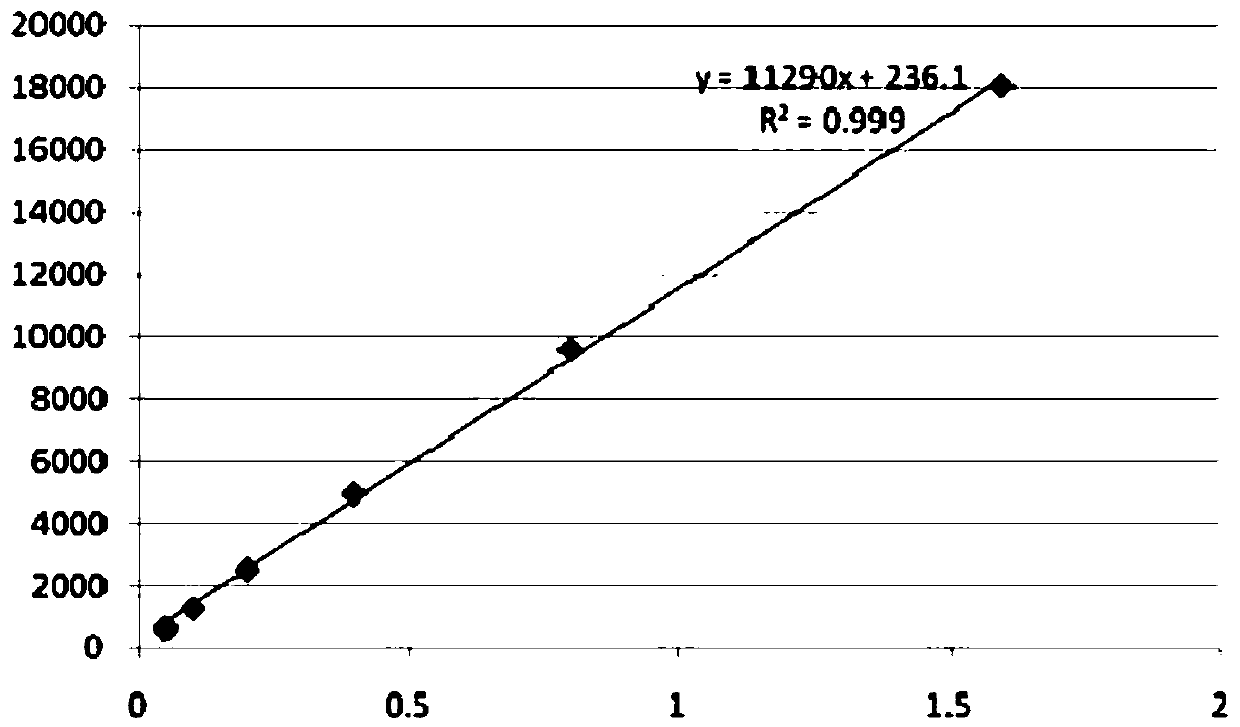

[0060] Pick 4 single colonies of transformants and 1 single colony of Escherichia coli MC4100 and inoculate them into 25ml liquid medium respectively (32g corn flour, 20g soybean meal, 13g peptone, 15g glucose, 2g KH 2 PO 4 and 1.20 g of ammonium sulfate were dissolved in purified water and adjusted to 1 L with purified water), 37 ° C, 200 rpm shaking culture for 12-18 h, 10000 rpm centrifugation for 10 min, and the supernatant was collected. The concentration of the target polypeptide Microcin J25 in the supernatant was detected by high performance liquid chromatography.

[0061] The high performance liquid chromatography chromatographic conditions are as follows:

[0062] Use octadecylsilane bonded silica gel as filler (high performance liquid chromatography: Agilent1260, C18 chromatographic column: ZORBAX 300SB-C18, 5μm, 4.6×250mm), and trifluoroacetic acid-water-acetonitrile (1:950: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com