Pot and preparation method and application thereof

A pot and pot body technology, applied in the field of pots, can solve the problems of long production line switching time, long enamel process time, high appearance defect rate, etc., and achieve the effects of reducing the risk of cracking, strong bonding force, and improving roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

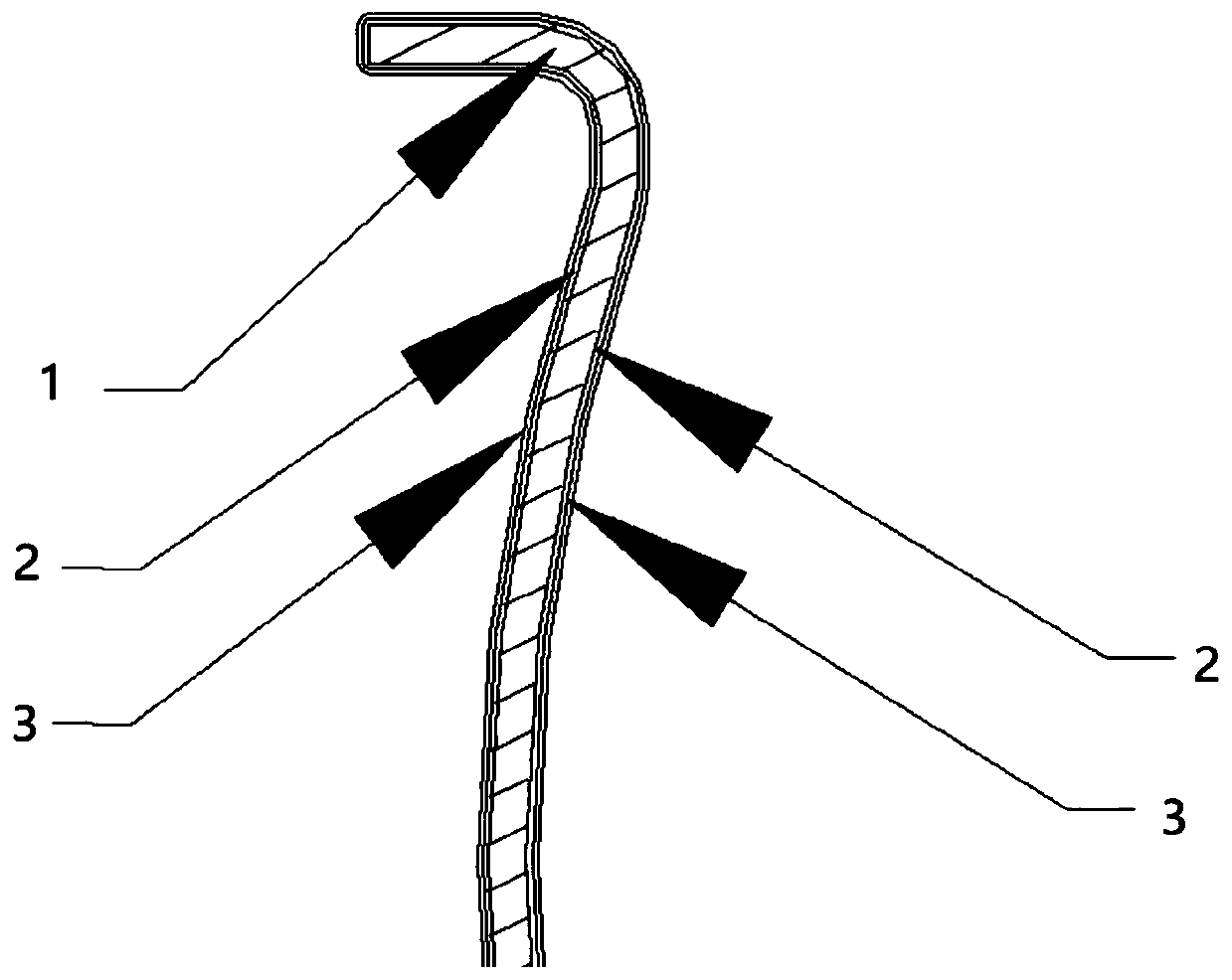

[0043] refer to figure 1 , The pot of the present application includes a pot body 1 and a bottom enamel layer 2 and a surface enamel layer 3 coated on the surface thereof. The pot body 1 is made of metal material. After the bottom glaze slurry is coated on the surface of the pot body 1 and the surface is dry, the bottom glaze slurry layer is formed. Finally, the bottom glaze slurry layer forms the bottom enamel layer 2, and the top glaze slurry forms the top enamel layer 3. Specifically, the surface of the pot body includes at least the inner surface part of the pot body that is in contact with the food when cooking food; preferably, the surface of the pot body includes the entire inner surface of the pot body; more preferably, the surface of the pot body includes the inner surface and the outer surface of the pot body Such as figure 1 shown.

[0044] Those skilled in the art can understand that the metal material of the pot body 1 can be selected from any metal element or ...

Embodiment approach

[0058] As a specific embodiment, a method for preparing a pot includes the following steps:

[0059] 1) After the iron-containing plate is formed into a pot body, the inner and outer surfaces of the pot body are cleaned, rust-proofed, shot blasted and rust-proofed again, wherein the surface roughness Ra of the pot body after shot blasting is 3.5 ~9; re-rust protection provides a new unprotected surface due to shot blasting to prevent rust on the surface of the iron plate. Anti-rust can be treated with silane, phosphating, vitrification, etc.;

[0060] 2) After coating the bottom glaze slurry on the inner surface and outer surface of the pot provided, the surface is dry to form a bottom glaze slurry layer;

[0061] 3) After the bottom glaze slurry layer is wetted with water, the surface glaze slurry is coated on the surface of the bottom glaze slurry layer, surface-dried, trimmed, sintered in a high-temperature sintering furnace and cooled, and the bottom glaze slurry layer for...

Embodiment 2

[0068] This embodiment proposes an electromagnetically heated electric heating pot, which includes a pot body, a pot cover and an electromagnetic heating element, and the pot body includes an outer pot and any pot according to Embodiment 1 placed in the outer pot. The electromagnetic heating element can be an electromagnetic coil or a heating disc. The electric heating pot can be a kitchen appliance that contains ingredients in an inner pot such as an electric rice cooker, an electric pressure cooker, and a cooking machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com