Optical fiber humidity sensor based on coarse cone, working principle thereof and preparation method thereof

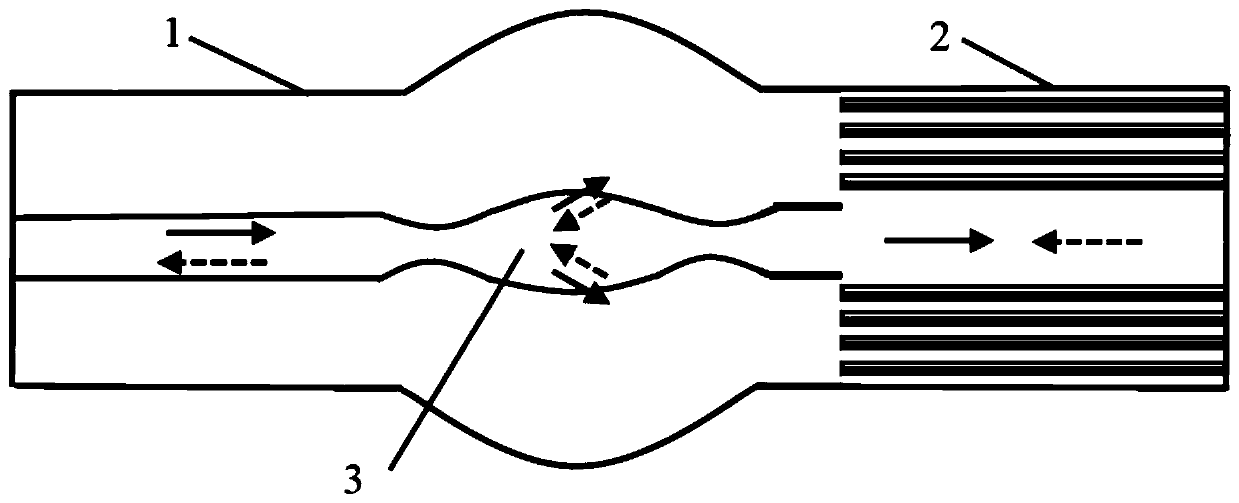

A humidity sensor and optical fiber technology, which is applied to the optical fiber humidity sensor based on thick cone and its working principle and preparation field, can solve the problems of complex production and low sensitivity, achieve a small sensor structure, improve coupling efficiency, and solve the problem of temperature and humidity cross sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

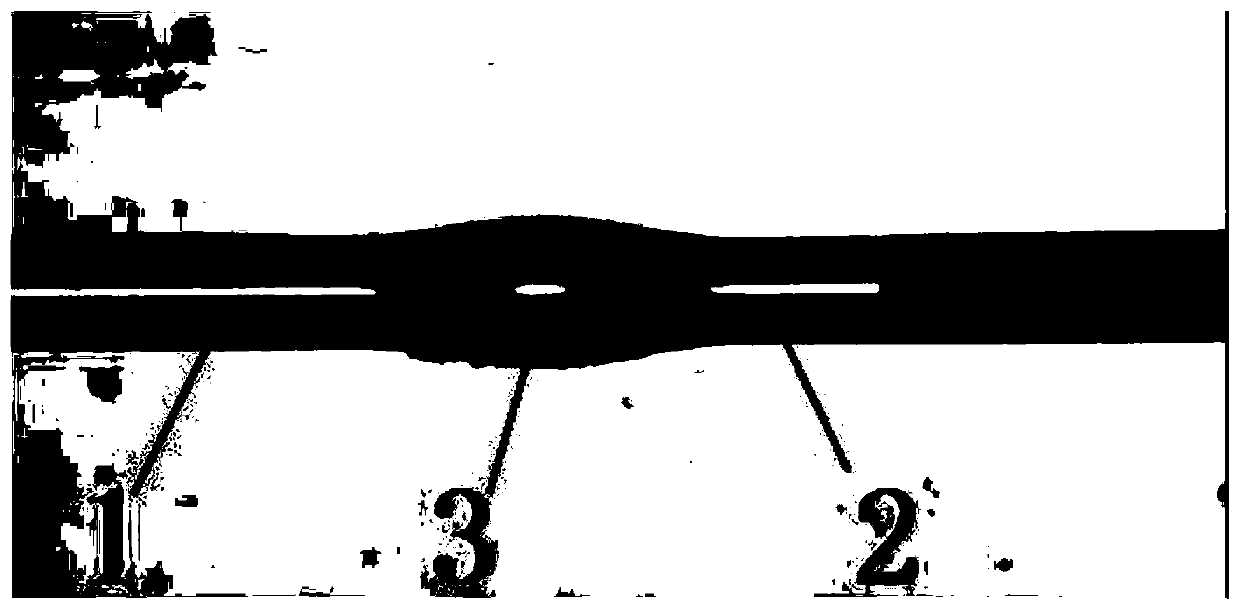

[0051] The preparation method of the optical fiber humidity sensor based on thick cone in the present embodiment, comprises the following steps:

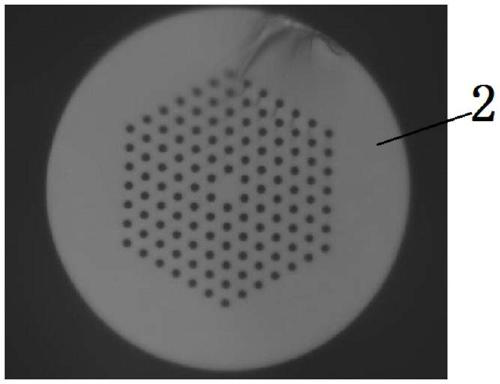

[0052] (1) Before welding, the end faces of ordinary single-mode fiber 1 and photonic crystal fiber 2 need to be cut flat and wiped clean with alcohol.

[0053] (2) Optical fiber thick cone fusion. Put the prepared optical fiber on the jig of the fusion splicer. In order to improve the splicing quality, fine-tune the X and Y directions of the jig to align the two optical fibers. The fusion splicing intensity is set to 130-140mA, the pre-melting time is set to 1400-1500ms, the advancing distance is set to 15-20μm, and the photonic crystal fiber is placed 5-10μm away from the electrode. The stomata are collapsed to obtain a more ideal interference spectrum.

[0054] (3) After the fusion splicing is completed, the end face of the photonic crystal fiber is accurately cut under the fiber cutter, and the length of the photonic crystal f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com