Self-dedusting monitoring camera lens and preparation method thereof

A surveillance camera, self-dust removal technology, applied in ion implantation plating, coating, instruments, etc., can solve the problems of small dust size, adhesion, difficulty in removal, dust reduction, etc., and achieve excellent self-cleaning effect and hydrophobicity. Good, keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

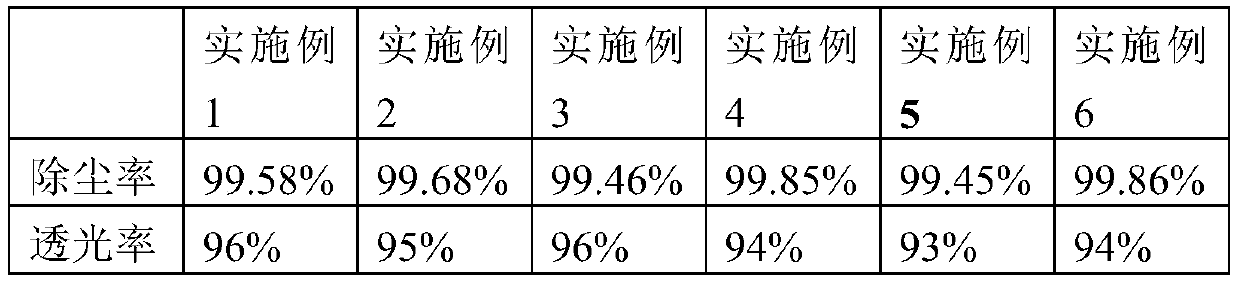

Embodiment 1

[0042] The preparation method of the self-dust-removing monitoring camera lens lens of the present embodiment comprises the following steps:

[0043] (1) Preparation of coating solution

[0044] 1.1 Take 1.0 g of carbon nanotubes and a sufficient amount of concentrated nitric acid solution with a mass fraction of 65%, heat and reflux in a water bath at a temperature of 78 to 82°C for 20 hours, and wash the product to obtain carboxylated carbon nanotubes. The amount is based on the amount that is more than 1.0 g of carbon nanotubes completely reacted, and the amount of concentrated nitric acid is 300 mL in the present embodiment;

[0045] 1.2 Take 0.5g of carboxylated carbon nanotubes, 100mL of chlorinated ethylene and 2mL of dimethylformamide, mix them, and stir and reflux in a water bath at 75°C for 18h to react;

[0046] 1.3 Cool the mixed solution, add the mixed solution to a 2500r / min high-speed centrifuge for centrifugation, recover the upper layer, wash the lower black ...

Embodiment 3

[0058] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0059] 1.1 Heat and reflux in a water bath at a temperature of 78°C for 18 hours,

[0060] 1.2 Stir and reflux in a water bath at 73°C for 15 hours to react;

[0061] 1.3 Dry the black solid in a vacuum oven at 45°C for 22 hours,

[0062] 1.4 The mixture was stirred and reacted in a water bath at 90°C for 20 hours;

[0063] 1.6 Ultrasound for 12 minutes to obtain a uniformly dispersed coating liquid

[0064] Example 3

[0065] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0066] 1.1 ...

Embodiment 4

[0072] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In the coating solution prepared in this embodiment, the concentration of per(17)fluorodecyltrimethoxysilane is 0.1 g / L, and the concentration of octadecylamine-modified carbon nanotubes is 0.8 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com