Carbon-doped titanium dioxide photocatalyst, and preparation method and application thereof

A technology of titanium dioxide and photocatalyst, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, physical/chemical process catalyst, etc., can solve the problems of small specific surface area, limitation, large band gap and unable to use visible light, etc., and achieve high degradation efficiency, fast degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is the preparation of carbon-doped titanium dioxide photocatalyst

[0033] S1. Terephthalic acid and isopropyl titanate [Ti(OC) with a molar ratio of 3:5:40:194 3 h 7 ) 4 ], methyl alcohol and DMF are mixed and added in the reactor with polytetrafluoroethylene;

[0034] S2. Place the reaction kettle in an oven, set the program, raise it to 150°C at a rate of 1°C / min, then keep it for 24h, and cool it down to room temperature naturally to obtain a precipitate;

[0035] S3. Cross-wash the precipitate obtained in step S2 with methanol and DMF, centrifuge, and vacuum-dry at 150° C. for 12 hours to obtain an activated titanium-based MOFs material;

[0036] S4. Transfer the activated MOFs material prepared in step S3 to a clean ceramic ark, then put it into a muffle furnace, raise the temperature to 350°C at a rate of 2°C / min and keep it warm for 8 hours, and then cool to room temperature with the furnace, A carbon-doped titania photocatalyst was obtained....

Embodiment 2

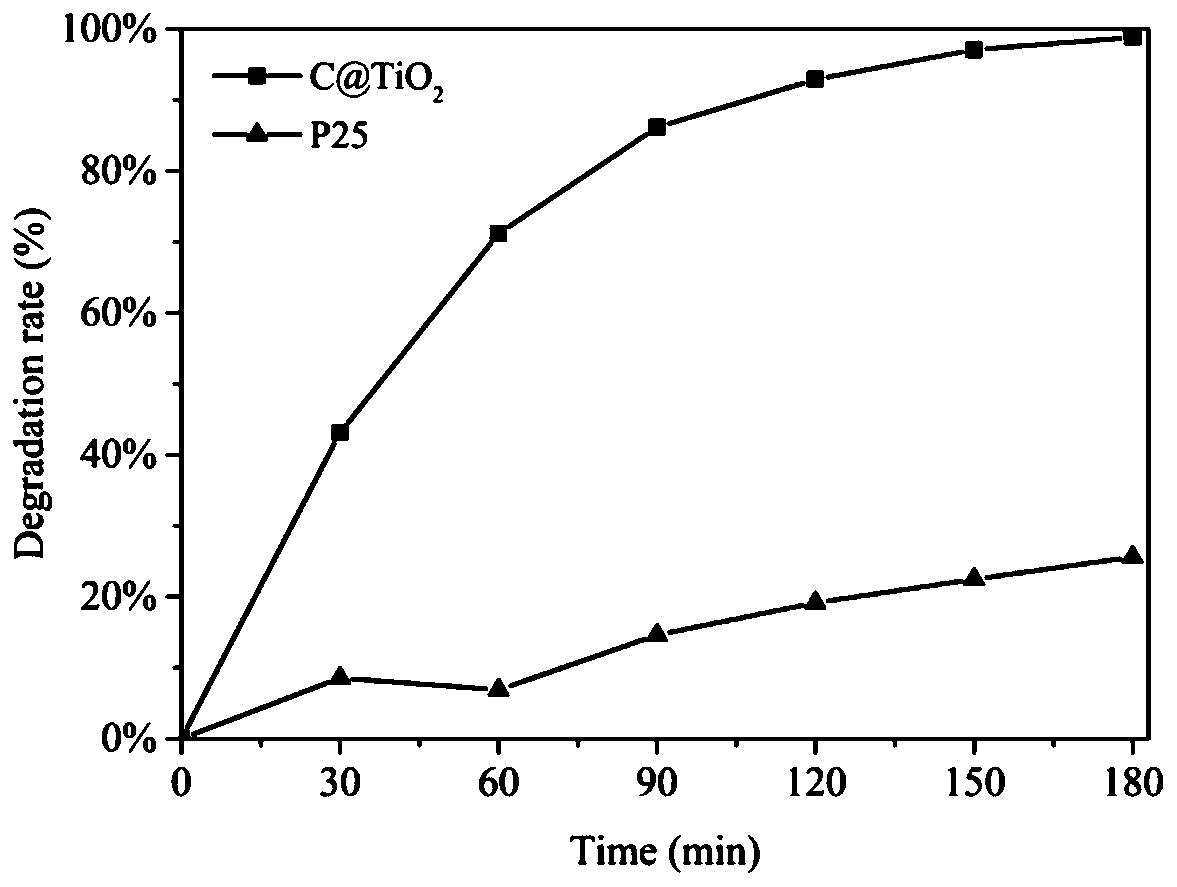

[0041] In this example, the carbon-doped titanium dioxide prepared in Example 1 is tested for its photocatalytic performance

[0042] The substrate of the photocatalytic reaction is bisphenol A, and the specific experimental process is as follows: 20 mg of the carbon-doped titanium dioxide sample prepared in Example 1 is added to a bisphenol A solution (100 mL) with a concentration of 20 ppm, and then under the action of visible light Carry out photocatalytic degradation reaction; Take out a certain amount of reaction solution every 30 minutes, carry out concentration measurement, degradation percentage is calculated according to the following formula: D (%)=(C 0 -C)×100 / C 0 , C 0 , C are the original concentration and final concentration, respectively. See the result image 3 .

[0043] image 3 The degradation curve of the carbon-doped titanium dioxide prepared in Example 1 of the present invention under visible light to degrade the organic pollutant bisphenol A. From ...

Embodiment 3

[0045] In this example, the carbon-doped titanium dioxide prepared in Example 1 is tested for its photocatalytic performance

[0046] The substrate of the photocatalytic reaction is phenol, and the specific experimental process is as follows: 20 mg of the carbon-doped titanium dioxide sample obtained in Example 1 is added to a phenol solution (100 mL) with a concentration of 20 ppm, and then photocatalytic degradation is carried out under the action of visible light Reaction, after 180min photocatalytic reaction, 20ppm phenol was degraded by 89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com