Environment-friendly preparation method of flexible polyimide heat insulation foam, and product

A polyimide, environment-friendly technology, applied in the field of environment-friendly preparation of flexible polyimide heat insulation foam, to achieve the effect of high controllability of experimental operation, environmental friendliness and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 11 grams of polar solvent N,N-dimethylformamide into a 100ml three-necked flask, put a magnet, add 23 grams of pyromellitic dianhydride, then put the flask into an oil bath, and set the heating temperature 125°C. Turn on the stirring and install the condensing reflux device. When the temperature of the emulsion reached 125° C., 17 grams of tert-butanol was added thereto for esterification. After 5 hours, the esterification reaction was complete, and the solution was clear and transparent. Stirring and heating were stopped to obtain a di-tert-butyl pyromellitic acid solution. The solution was lowered to room temperature for use, and the solid content was 78.4%.

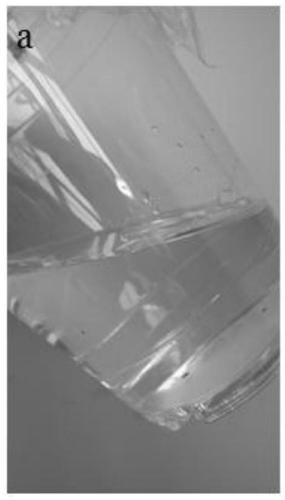

[0034] see in conjunction figure 1 , figure 1 This is a digital photo of the carboxylate solution prepared with tert-butanol in Example 1 after it was placed at room temperature at 20° C. for 36 hours.

Embodiment 2

[0039] In the di-tert-butyl pyromellitic acid solution prepared in embodiment example 1, 2.2 grams of composite catalysts, 3 grams of AK8805 foam stabilizer, 2.6 grams of desulfurized The ionic water foaming agent is stirred evenly at room temperature to obtain a compound slurry. Add 27 grams of diphenylmethane diisocyanate to the compound slurry, stir and mix quickly with a high-speed stirring paddle to obtain a foam slurry, quickly pour it into a mold for free foaming, and obtain a foam intermediate. After the body is shaped, it is placed in a high-temperature oven at 180°C for 1.5 hours of high-temperature curing, and then the temperature is raised to 240°C for another hour of curing. A flexible polyimide thermal insulation foam with regular cell structure was obtained.

[0040] During the preparation process of the flexible polyimide foam, the volatilization amount of the solvent is only 12.8% of the mass of the foam slurry, and the three-dimensional shrinkage rate of len...

Embodiment 3

[0044] Add 9 grams of polar solvent N,N-dimethylformamide into a 100ml three-necked flask, put in a magnet, add 23 grams of pyromellitic dianhydride, then put the flask into an oil bath, and set the heating temperature 125°C. Turn on the stirring and install the condensing reflux device. When the temperature of the emulsion reached 135° C., 19 grams of isoamyl alcohol was added thereto for esterification. After 6 hours, the esterification reaction was complete, and the solution was clear and transparent. Stirring and heating were stopped to obtain a diisoamyl pyromellitic acid solution, which was cooled to room temperature for use. The solid content was 82.4%.

[0045] Add 3.0 grams of composite catalyst, 4 grams of AK8805 foam stabilizer, and 4 grams of deionized water blowing agent to the above-mentioned diisoamyl pyromellitic acid solution. , and stir evenly to obtain compound slurry. Add 27.5 grams of triphenylmethane triisocyanate to the compound slurry, stir and mix q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com