Method for preparing hydrophobic porous wollastonite ceramic membrane for desalination by taking high-silicon high-calcium industrial solid waste as raw material through tape casting

A solid waste, tape casting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

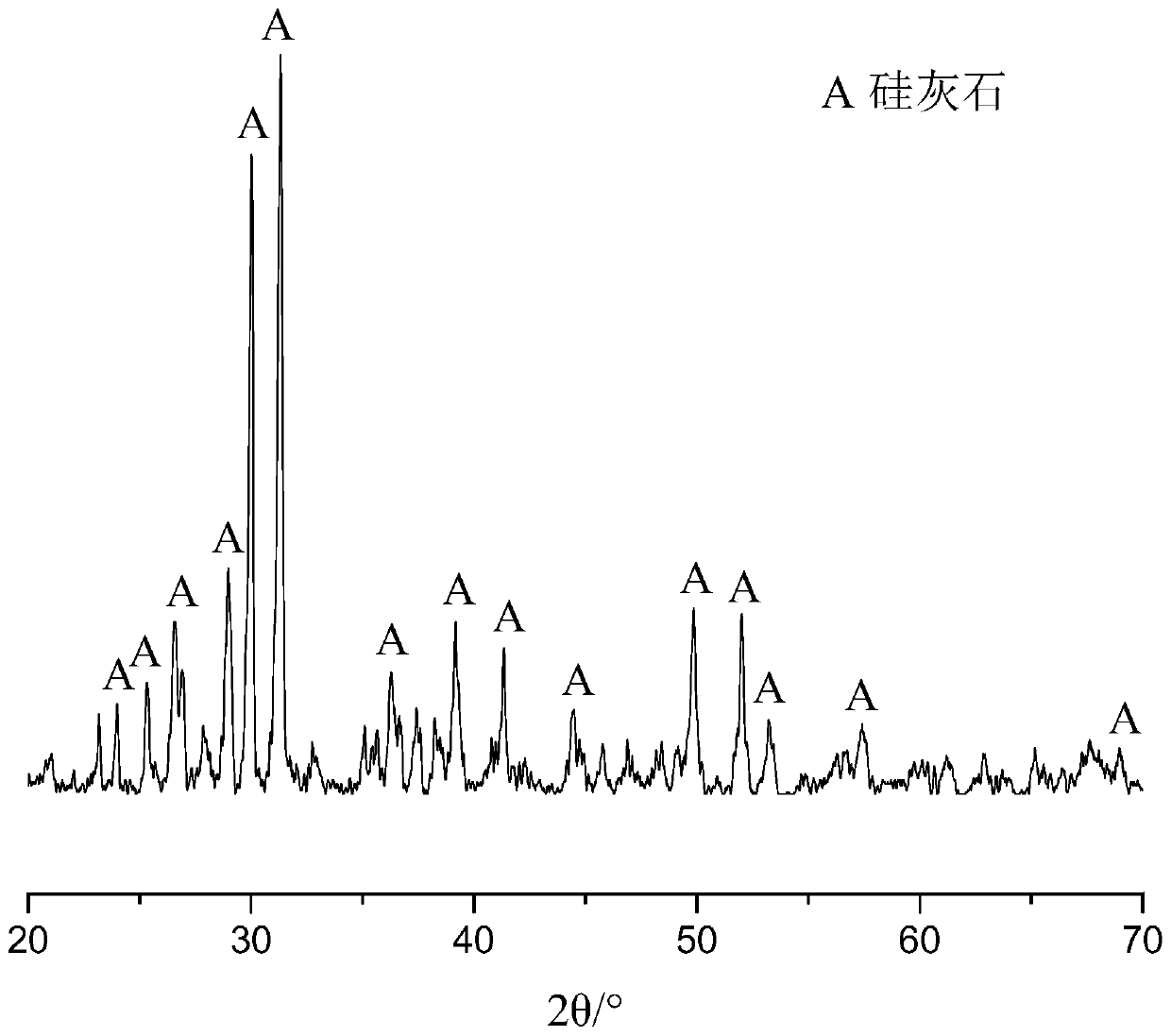

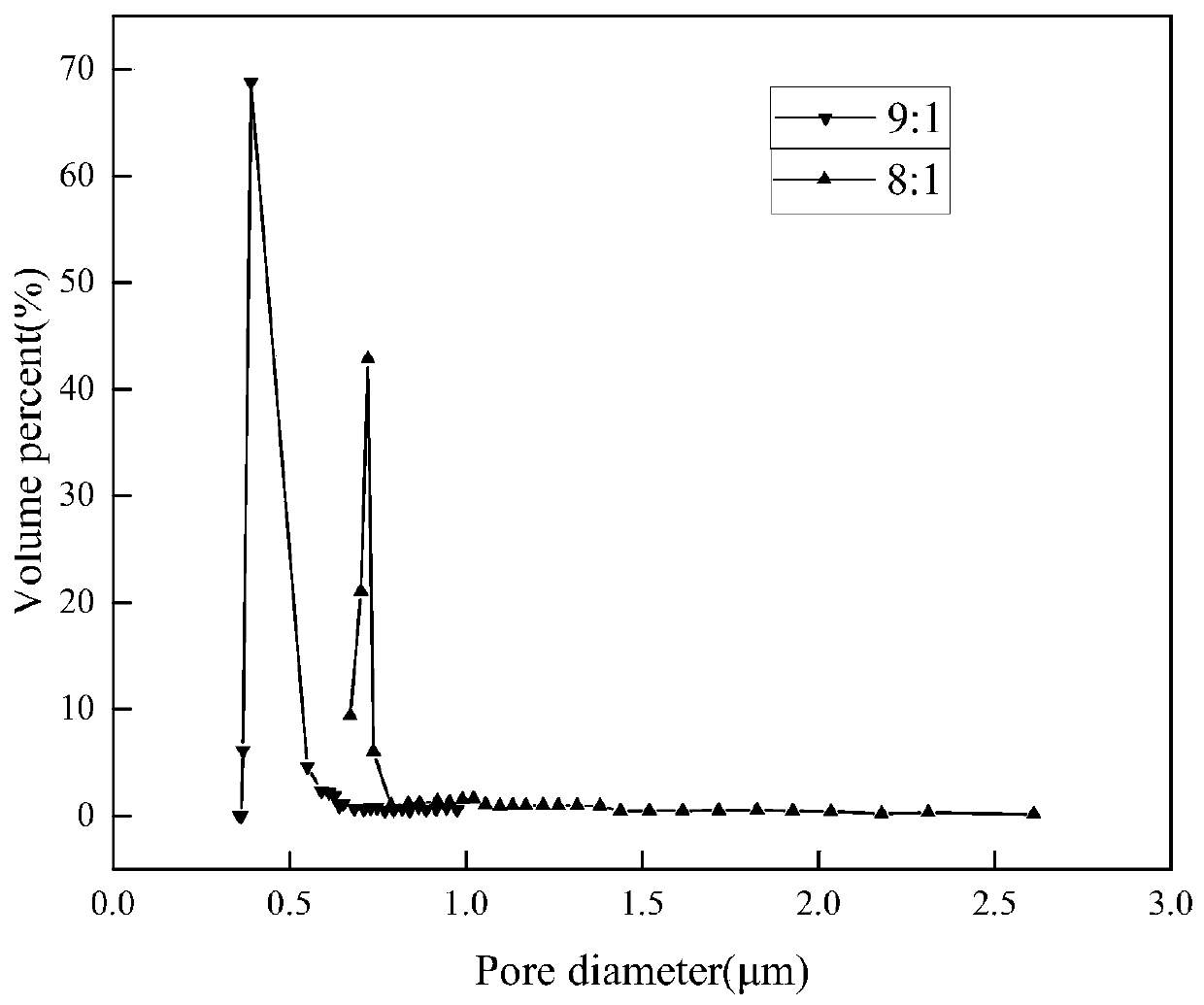

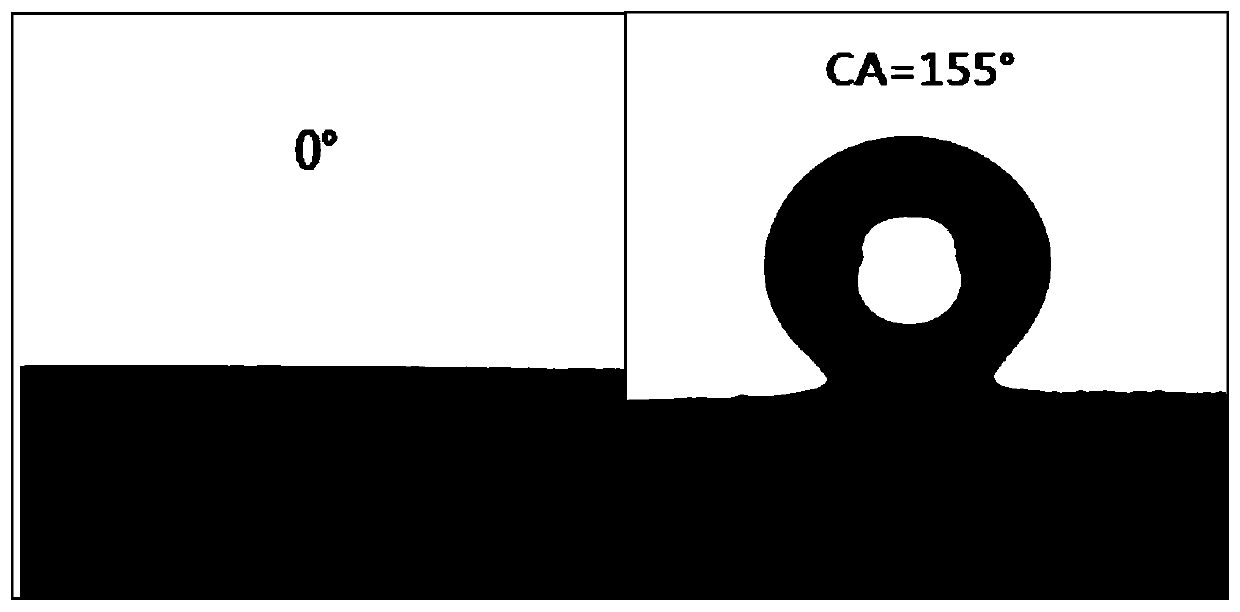

[0035] The solid waste was washed with deionized water until neutral, and dried at 120°C for 3 hours for use. Take 110g of solid waste after washing and drying in a muffle furnace, and activate it at 540°C for one hour. Take activated solid waste 50g, 8.865gCaO, 7.205gSiO 2 and absolute ethanol are added to the ball mill tank together, and the mass ratio is ball milling beads: wollastonite raw material: absolute ethanol is 300:60:12. Weigh the material according to the same mass and add it to another symmetrical ball mill tank, and mill for 5 hours. The slurry obtained after ball milling was transferred into a beaker and dried at 100°C for 24 hours. After drying, the sample was pulverized and passed through a 300-mesh standard sieve for use. Measure 56g of NMP, 7g of PESf, and 2.24g of PVP, put the above components into a ball mill jar and mill for 2 hours to obtain a well-mixed organic solution. Weigh 56 g of wollastonite raw material and sieve the powder into a uniformly m...

Embodiment 2

[0037] The solid waste was washed 10 times with distilled water until neutral, and dried at 120 °C for 4 h. Take 110g of washed and dried solid waste into a muffle furnace, raise the temperature to 540°C for activation for one hour, and take 50g of activated solid waste, 8.865g of CaO, and 7.205g of SiO 2and absolute ethanol are added to the ball mill tank together, and the mass ratio is ball milling beads: wollastonite raw material: absolute ethanol is 300:60:12. Weigh the material according to the same mass and add it to another symmetrical ball mill tank, and mill for 5 hours. The slurry obtained after ball milling was transferred into a beaker and dried at 100°C for 24 hours. After drying, the sample was pulverized and passed through a 300-mesh standard sieve for use. Measure 56g of NMP, 7g of PESf, and 2.24g of PVP, put the above components into a ball mill jar and mill for 2 hours to obtain a well-mixed organic solution. Weigh 56 g of wollastonite raw material and sieve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com