A method for regulating the growth of covalent carbon-nitrogen polymerization photocatalysts on two-dimensional honeycomb carbon nanosheets

A photocatalyst, carbon nanosheet technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of inaccurate regulation and high energy consumption , to achieve the effect of good catalytic degradation performance, high growth efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

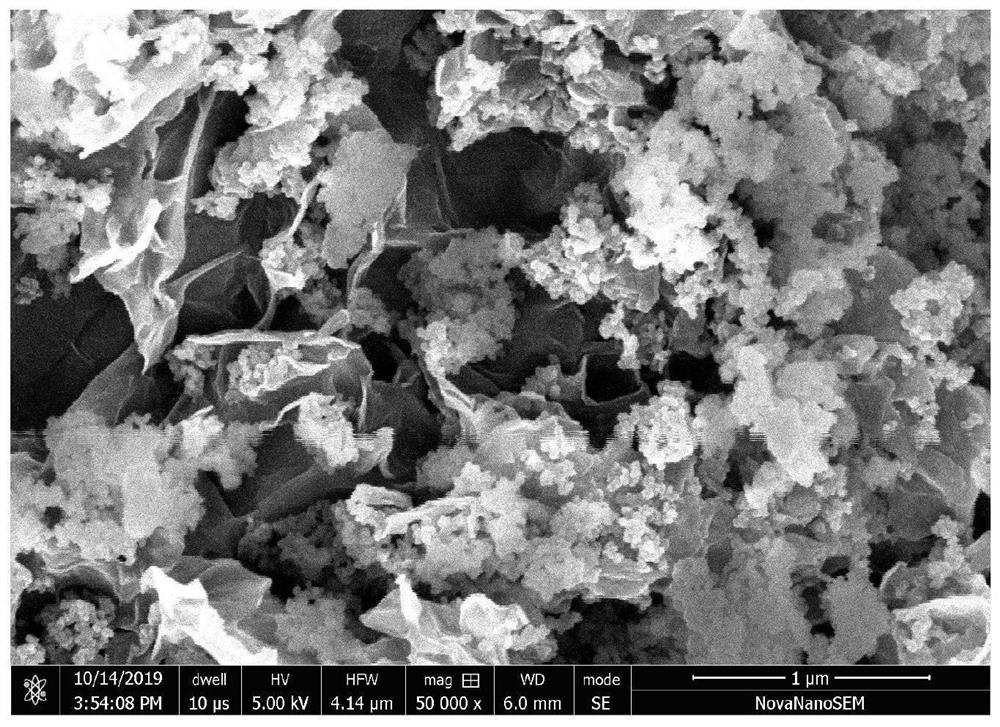

Embodiment 1

[0023] In this example, the specific steps for preparing two-dimensional honeycomb carbon nanosheets for growing covalent carbon-nitrogen polymerization photocatalysts are as follows:

[0024] (1) Add 6 mL of hydrazine hydrate solution with a mass fraction of 50% and 1 g of sodium lauryl sulfate to 125 mL of 2 mg / mL graphene oxide dispersion, and stir at 80°C for 12 h, hydrazine hydrate will The graphene oxide is partially reduced to obtain a reduced graphene oxide dispersion.

[0025] (2) Mix 2.86 g of 4-aminobenzonitrile and 22.09 g of tetrafluoroboric acid solution with a mass fraction of 48%, stir at 0°C for 10 min, then slowly add sodium nitrite solution (1.5 g of sodium nitrite solution solution in 10 mL of water), and continued to stir at 0°C for 30 min to form a 4-cyanodiazonium tetrafluoroborate solution.

[0026] (3) Slowly add the 4-cyanodiazobenzenetetrafluoroborate solution obtained in step (2) dropwise into the reduced graphene oxide dispersion obtained in step ...

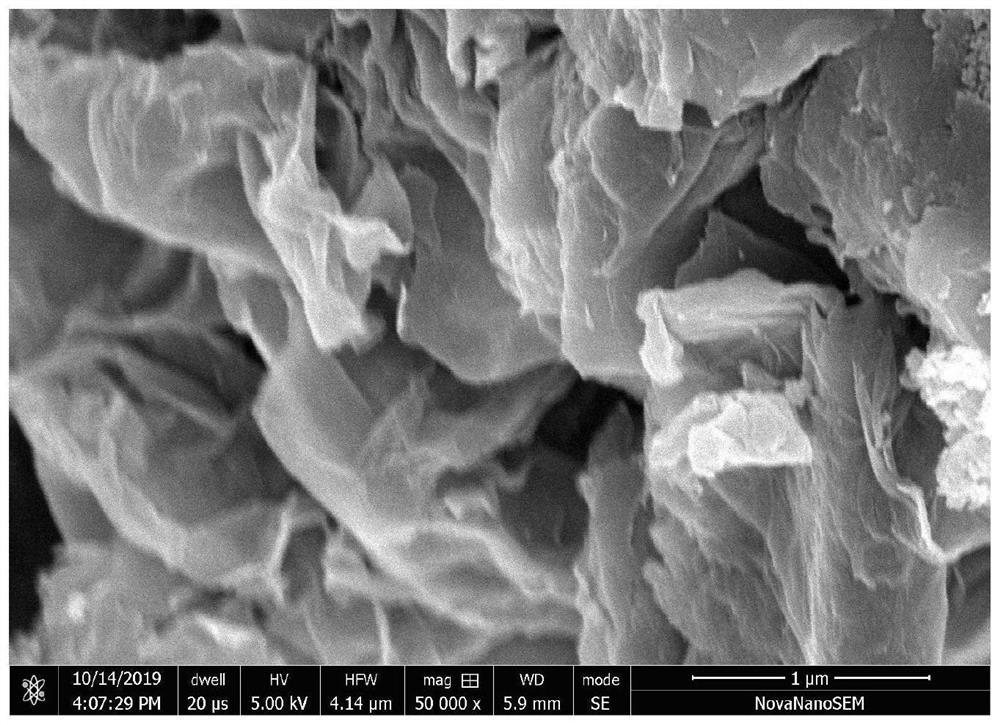

Embodiment 2

[0031] (1) Add 6 mL of hydrazine hydrate solution with a mass fraction of 50% and 1 g of sodium lauryl sulfate to 125 mL of 2 mg / mL graphene oxide dispersion, and stir at 80°C for 12 h, hydrazine hydrate will The graphene oxide is partially reduced to obtain a reduced graphene oxide dispersion.

[0032](2) Mix 2.86 g of 4-aminobenzonitrile and 22.09 g of tetrafluoroboric acid solution with a mass fraction of 48%, stir at 0°C for 10 min, then slowly add sodium nitrite solution (1.5 g of sodium nitrite solution solution in 10 mL of water), and continued to stir at 0°C for 30 min to form a 4-cyanodiazonium tetrafluoroborate solution.

[0033] (3) Slowly add the 4-cyanodiazobenzenetetrafluoroborate solution obtained in step (2) dropwise into the reduced graphene oxide dispersion obtained in step (1), then vigorously stir at room temperature for 2 h, after the reaction Centrifuge to remove the supernatant, wash the remaining solid with acetone and water for 1-3 times, and place in...

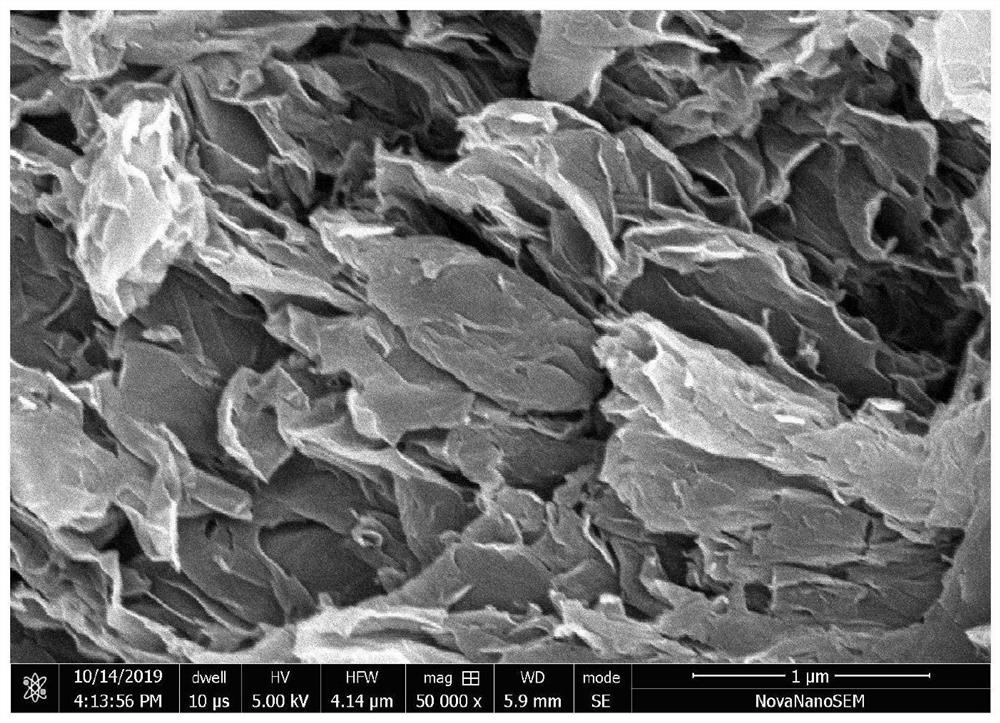

Embodiment 3

[0038] (1) Add 6 mL of hydrazine hydrate solution with a mass fraction of 50% and 1 g of sodium lauryl sulfate to 125 mL of 2 mg / mL graphene oxide dispersion, and stir at 80°C for 12 h, hydrazine hydrate will The graphene oxide is partially reduced to obtain a reduced graphene oxide dispersion.

[0039] (2) Mix 2.86 g of 4-aminobenzonitrile and 22.09 g of tetrafluoroboric acid solution with a mass fraction of 48%, stir at 0°C for 10 min, then slowly add sodium nitrite solution (1.5 g of sodium nitrite solution solution in 10 mL of water), and continued to stir at 0°C for 30 min to form a 4-cyanodiazonium tetrafluoroborate solution.

[0040] (3) Slowly add the 4-cyanodiazobenzenetetrafluoroborate solution obtained in step (2) dropwise into the reduced graphene oxide dispersion obtained in step (1), then vigorously stir at room temperature for 2 h, after the reaction Centrifuge to remove the supernatant, wash the remaining solid with acetone and water for 1-3 times, and place i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com