Intelligent steel rail drilling machine based on torque shell pushing cover cap of clamp base

A technology of clamp holder and drilling machine, which is applied in boring/drilling, drilling/drilling equipment, rails, etc., can solve the problem of low working efficiency of rail drilling machine, unqualified rail inspection, and high cost. Problems such as manpower and labor, to facilitate the two-way potential control work and improve the effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

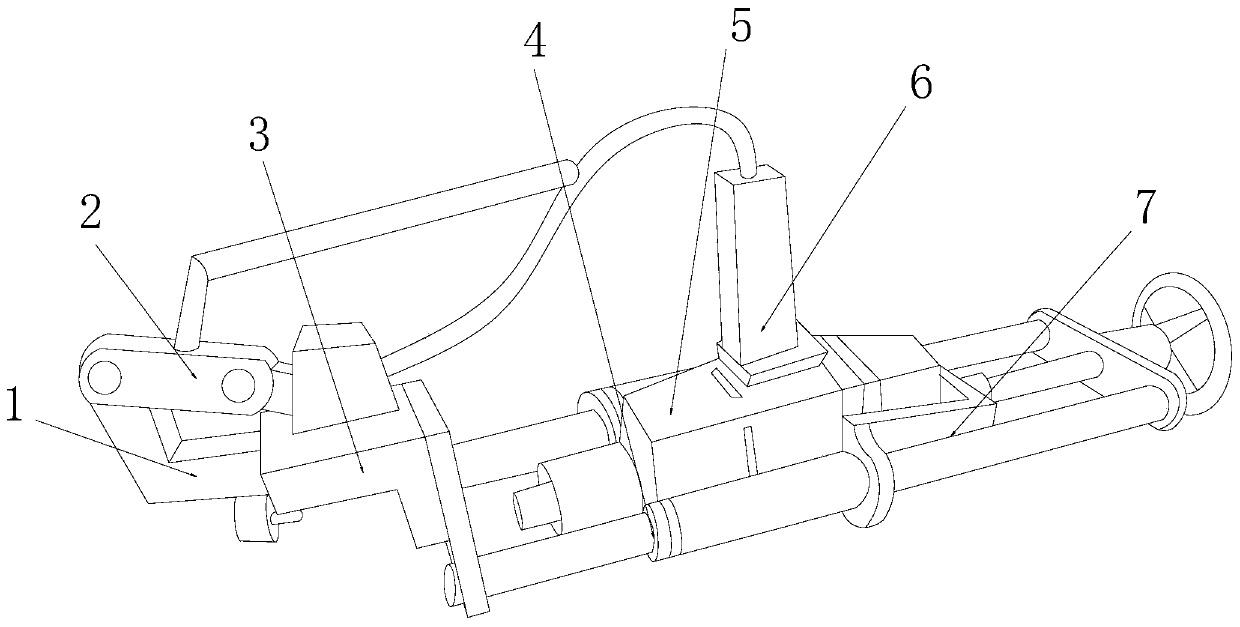

[0032] see Figure 1-Figure 7 , the present invention provides a kind of intelligent rail drilling machine based on the torque push shell cap of the clamp clamp seat, its structure includes: a pin rod folding support arm 1, a portable pressing rod seat 2, a torque push cover plate seat 3, a hydraulic cylinder Column frame 4, axial motor 5, power distribution seat 6, three-bar pressure bearing frame 7, the torque push cover plate seat 3 is nested on the left side of the hydraulic cylinder column frame 4, and the pin rod folding support arm 1 is welded On the left side of the torque push cover plate seat 3, the pin rod folding support arm 1 is mechanically connected with the portable pressing bar seat 2 and is on the same vertical plane, and the hydraulic cylinder column frame 4 is provided with two and respectively close On the front and rear sides of the shaft motor 5, the power distribution base 6 is inserted on the top of the shaft motor 5 and is perpendicular to each other....

Embodiment 2

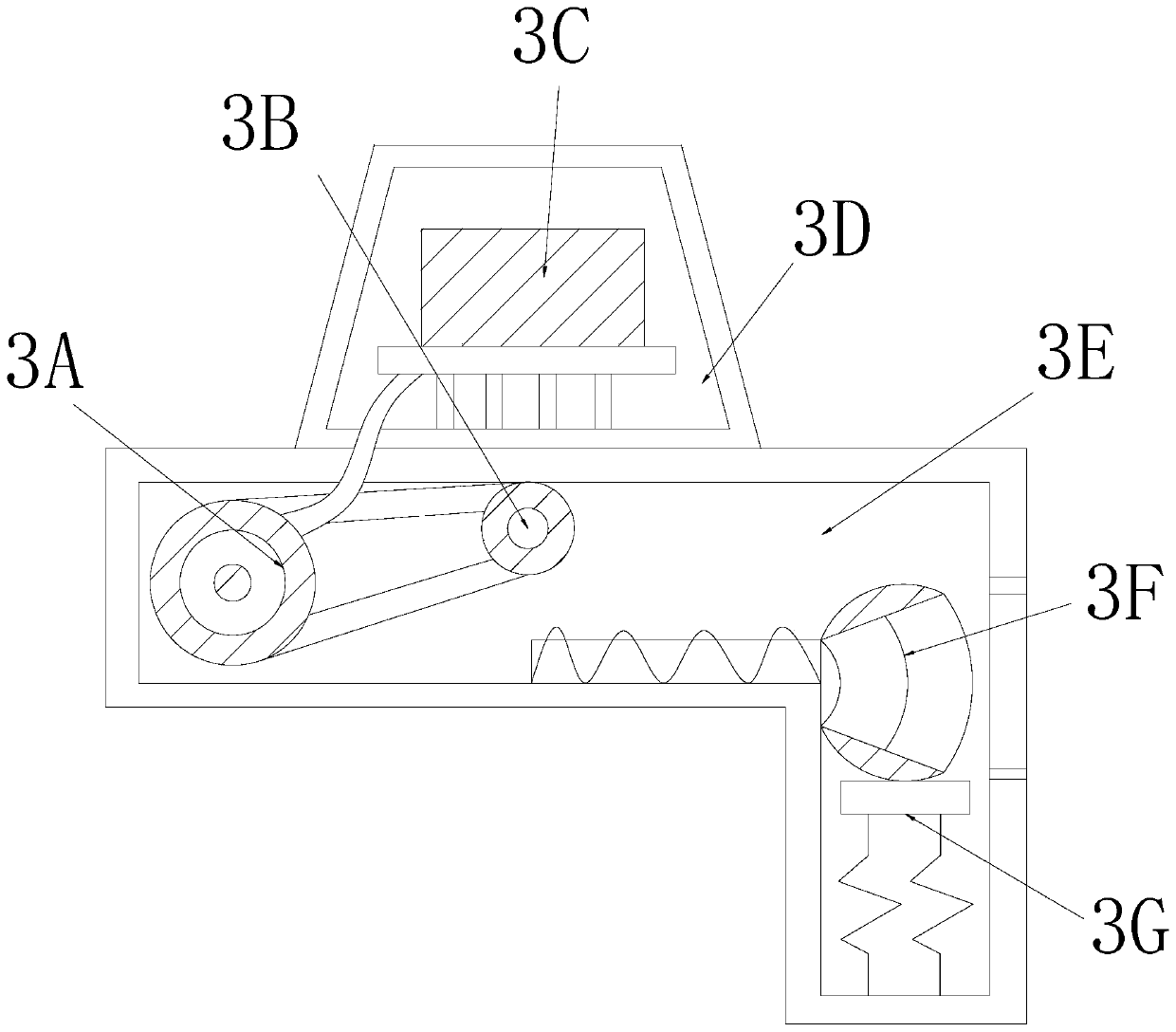

[0038] see Figure 1-Figure 7 , the present invention provides a kind of intelligent rail drilling machine based on the torque of the clamp clamp seat to push the shell cap, other aspects are the same as embodiment 1, the difference is:

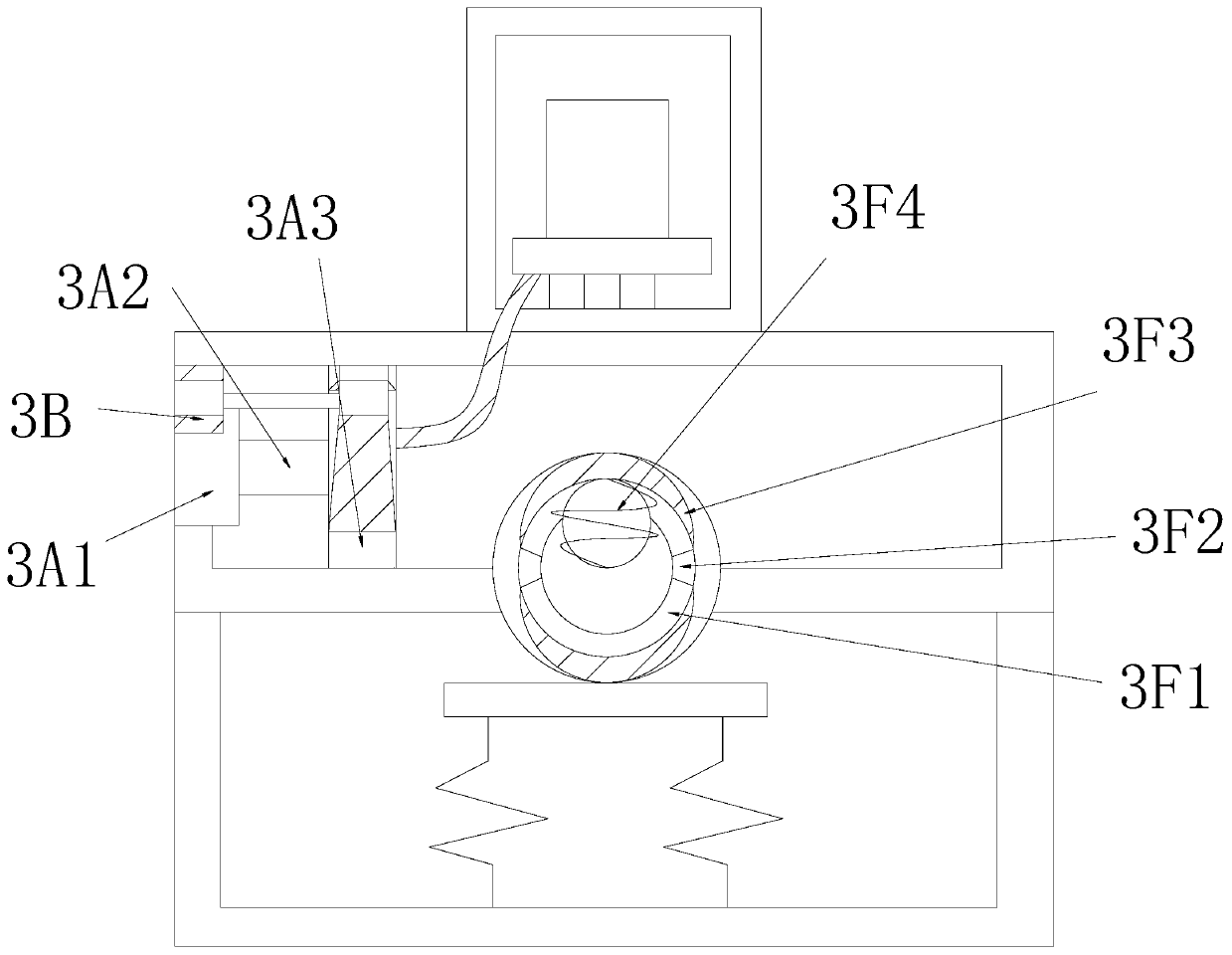

[0039] see Figure 5 , the suction stick clamp wheel 3B is composed of eccentric suction cup groove 3B1, internal pressure arc groove pad 3B2, clamp wheel frame ring 3B3, air bag bar groove 3B4, and described eccentric suction cup groove 3B1 and internal pressure arc groove pad 3B2 are all provided with six and alternately close together around the center of the clamp wheel frame ring 3B3, the airbag strip groove 3B4 is fastened together with the clamp wheel frame ring 3B3 and is on the same vertical plane, and the airbag strip groove 3B4 is pointed and narrow up and down. The wide and thick tapered airbag groove structure with arc plate in the middle achieves the airbag operation that the ring surface is tightly pressed separately, ensuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com