Reduction treatment process for landfill leachate concentrate

A landfill leachate and treatment process technology, which is applied in the field of landfill leachate concentrate reduction treatment process, can solve the problems of weak ozone utilization rate and degradation effect, unfavorable refractory organic matter and salt, and low adverse effects of advanced oxidation method , to achieve the effects of less incineration content, long-term stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

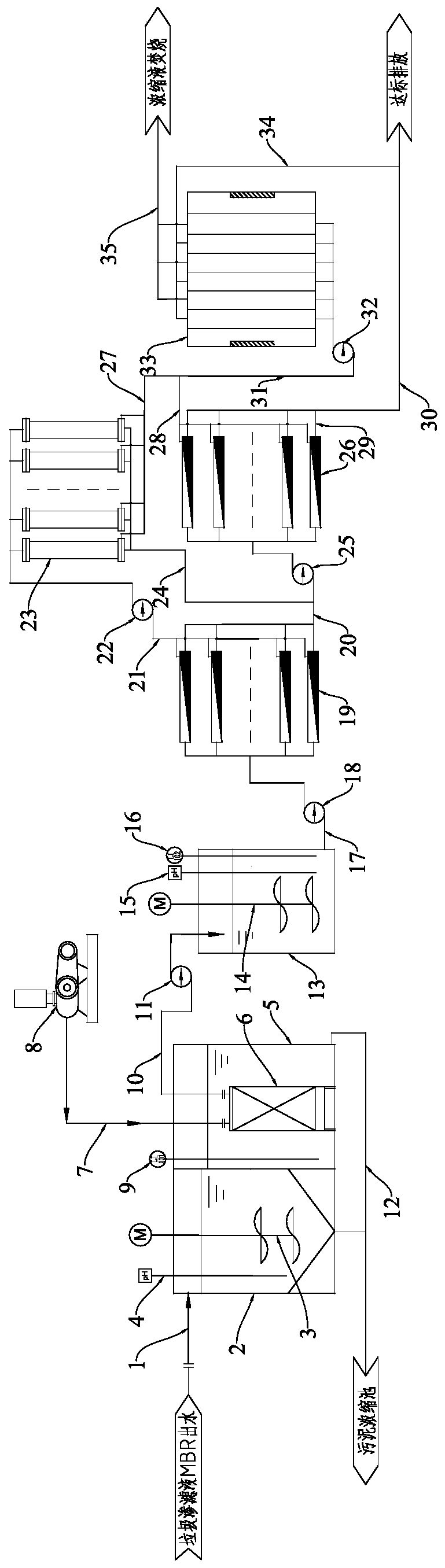

[0046] A process for reducing the amount of landfill leachate concentrate, comprising the following steps:

[0047] Step 1. The landfill leachate MBR effluent enters the first chemical reaction tank in the first chemical dosing system through the MBR water production pipe, and an appropriate amount of lime and soda ash are added to the first chemical reaction tank to adjust the pH to 10;

[0048] Step 2, the reaction liquid in the first chemical reaction tank flows into the MCR pool in the MCR system through the overflow port on the upper part of the first chemical reaction tank;

[0049] Step 3: The produced water of the MCR system enters the second dosing reaction tank in the second dosing system through the MCR produced water pump, and an appropriate amount of sulfuric acid is added to the second dosing reaction tank, and the sulfuric acid and the MCR produced water are evenly stirred by the second agitator , so that the two are fully mixed, and the pH is adjusted to 6.5; ...

Embodiment 2

[0054] The specific method of the present embodiment is the same as that of Example 1, and only the operating parameters are changed as follows: add an appropriate amount of lime and soda ash in the first medicament reaction tank, and adjust the pH to 11; the second dosing reaction tank adds an appropriate amount of sulfuric acid to adjust the pH to 7.

Embodiment 3

[0056] The specific method of the present embodiment is the same as that of Example 1, and only the operating parameters are changed as follows: add an appropriate amount of lime and soda ash in the first chemical reaction tank, and adjust the pH to 12; 6.

[0057] After the treatment in the above examples, the water produced by the EDR system and the RO membrane system was mixed and then tested. The test results were compared with my country's "Standards for Pollution Control of Domestic Waste Landfill" (GB16889-2008), see Table 1 for details:

[0058] Table 1 Influent and effluent water quality indicators

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com