Method for extracting shikimic acid and quinic acid from ginkgo leaves

A technology of shikimic acid and ginkgo biloba, which is applied in the separation/purification of carboxylic acid compounds, organic chemistry, bulk chemical production, etc., can solve the problems of large amount of wastewater treatment, environmental pollution, cumbersome operation, etc. The effect of reducing environmental pollution and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

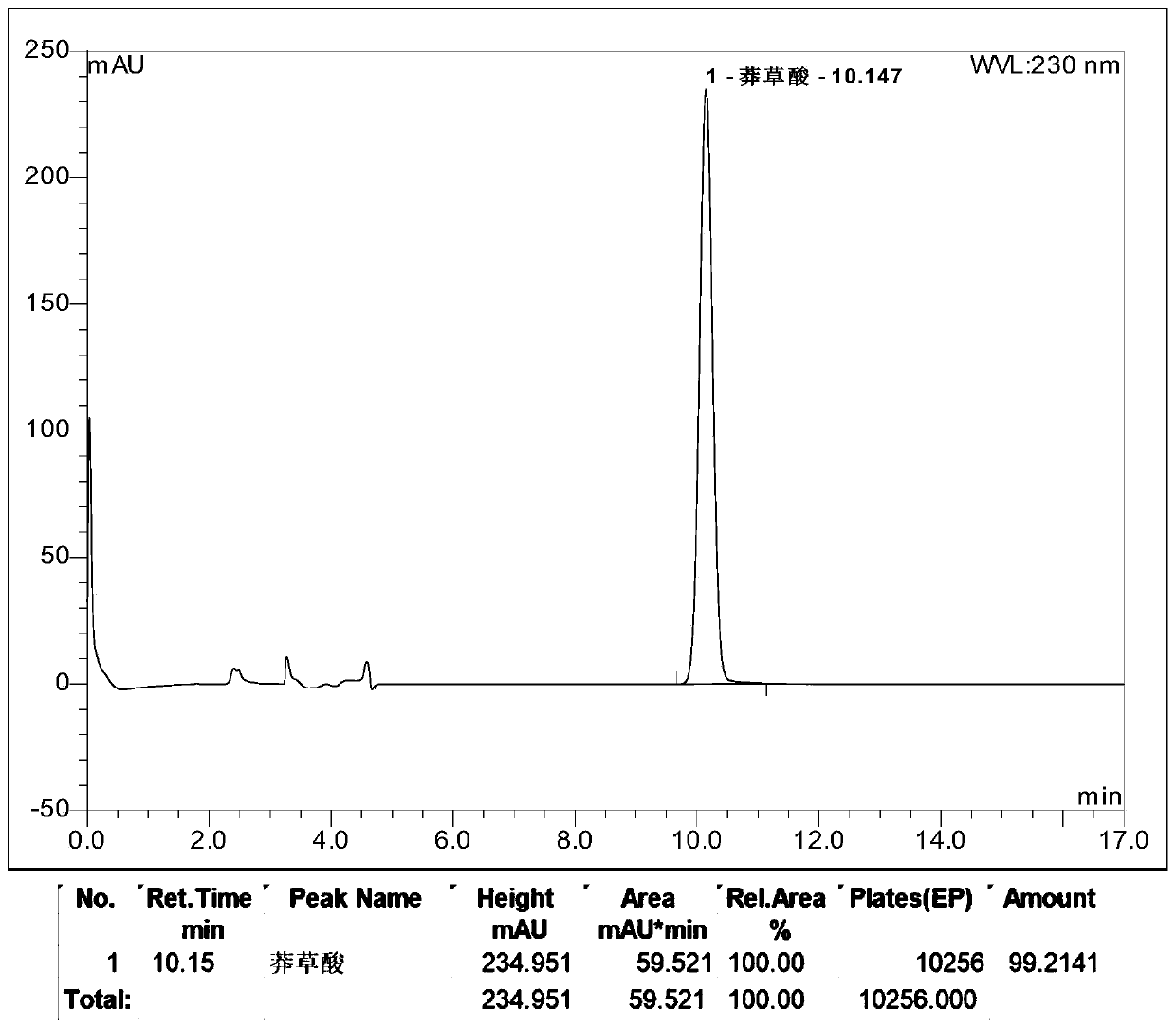

Embodiment 1

[0055] Cut 5 kg of fresh ginkgo leaves into pieces and add them to the extraction kettle. Use 5LpH=8 acetone solution as the entrainer. The pressure of the extraction kettle is 28MPa, the extraction temperature is 55°C, the extraction time is 1.5h, the pressure of No. 45°C, No. 2 separation tank pressure 6MPa, temperature 40°C. The extract (A) is obtained from No. 1 separation tank, the extract (A) is rich in chlorophyll, and the purification of product I chlorophyll can be continued. The extraction residue (B) is obtained in the extraction kettle. The extraction residue (B) is digested with alkaline water to inactivate the enzyme. For example, 5 times the amount of sodium bicarbonate aqueous solution can be used to cook at 100 ° C. After inactivating the enzyme, take it out, extract it twice with ethanol, combine the extracts, and concentrate the extracts to neutral. Filter the supernatant. Add polyamide to the supernatant [the mass ratio of supernatant to polyamide is 3:1]...

Embodiment 2

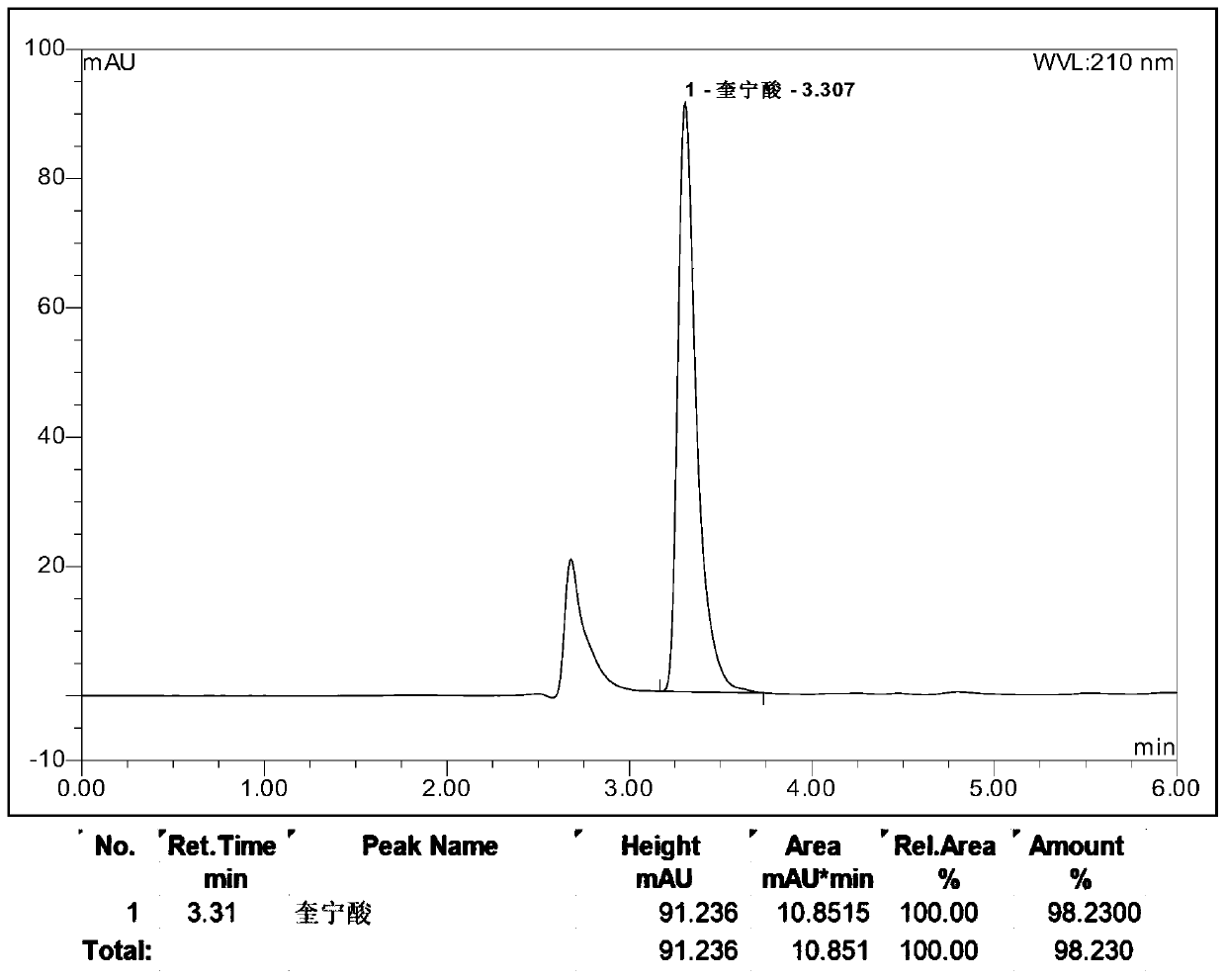

[0060] Cut 5 kg of fresh ginkgo leaves into pieces, add them to the extraction kettle, use 10LpH=8.5 acetone solution as the entrainer, the pressure of the extraction kettle is 30MPa, the temperature of the extraction kettle is 50°C, the extraction time is 2h, the pressure of No. 1 separation kettle is 8MPa, the temperature 40°C, No. 2 separation kettle pressure 6MPa, temperature 40°C. The extract (A) is obtained from No. 1 separation tank, the extract (A) is rich in chlorophyll, and the purification of product I chlorophyll can be continued. The extraction residue (B) is obtained in the extraction kettle. The extraction residue (B) is digested with alkaline water to inactivate the enzyme. After inactivating the enzyme, take out and extract twice with ethanol, combine the extracts, concentrate the extracts to be neutral, and filter to obtain the supernatant. Add polyamide to the supernatant [the mass ratio of supernatant to polyamide is 3:1], stir for 30 minutes and filter t...

Embodiment 3

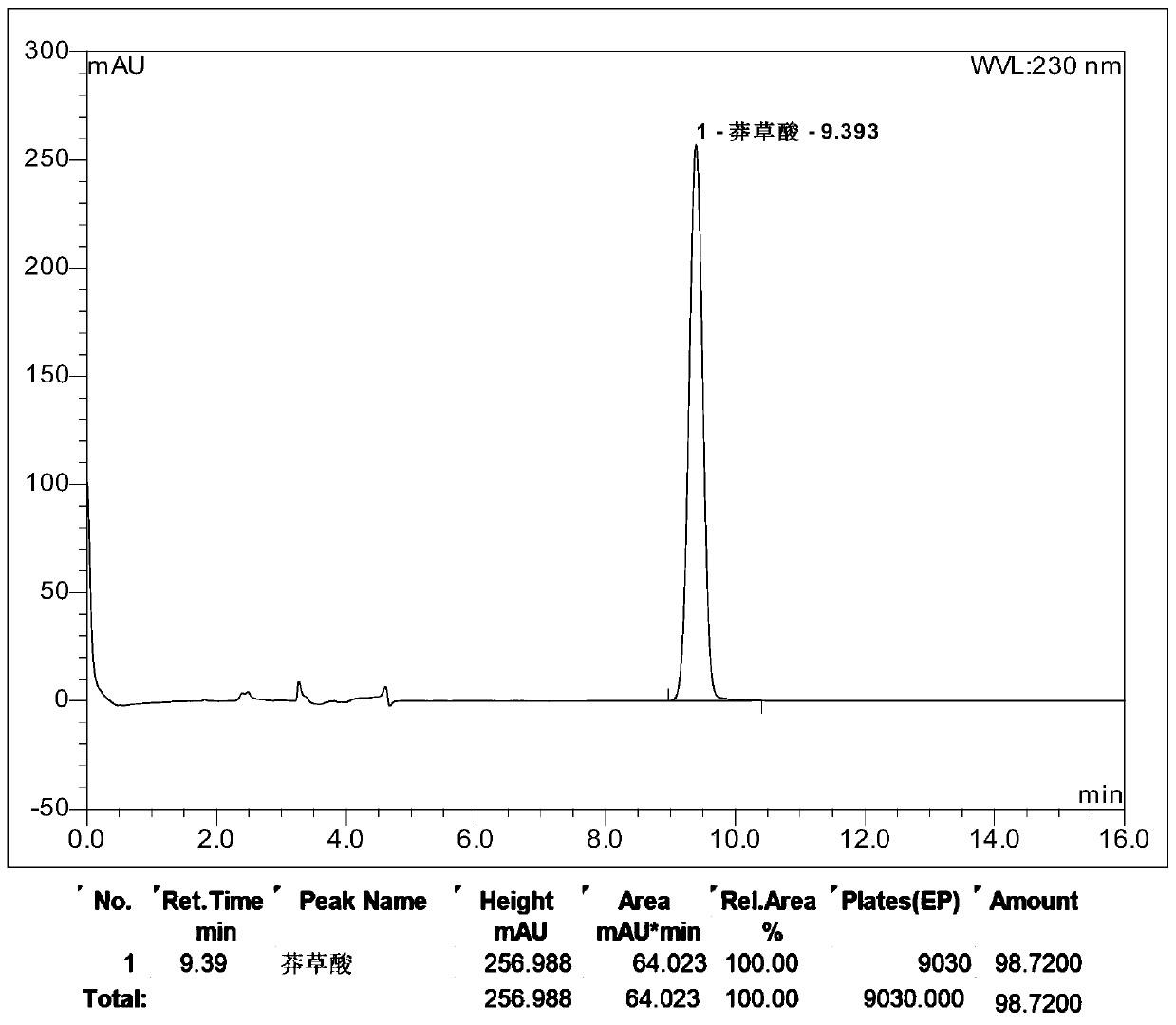

[0063] Cut 5 kg of fresh ginkgo leaves into pieces, add them to the extraction kettle, use 8LpH=8 acetone solution as the entrainer, the pressure of the extraction kettle is 28MPa, the extraction temperature is 50°C, the extraction time is 1.5h, the pressure of No. 1 separation kettle is 8MPa, and the temperature 45°C, No. 2 separation tank pressure 6MPa, temperature 40°C. The extract (A) is obtained from No. 1 separation tank, the extract (A) is rich in chlorophyll, and the purification of product I chlorophyll can be continued. The extraction residue (B) is obtained in the extraction kettle. The extraction residue (B) is digested with alkaline water to inactivate the enzyme. After inactivating the enzyme, take out and extract twice with ethanol, combine the extracts, concentrate the extracts to be neutral, and filter to obtain the supernatant. Add polyamide to the supernatant [the mass ratio of supernatant to polyamide is 3:1] to obtain filtrate (C) (for standby) and preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com