Glycyrrhetinic acid derivative ASBT as well as preparation method and application thereof

A technology of glycyrrhetinic acid and derivatives, applied in the direction of drug combination, pharmaceutical formula, steroidal compounds, etc., to achieve the effect of mild reaction conditions, excellent performance, and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

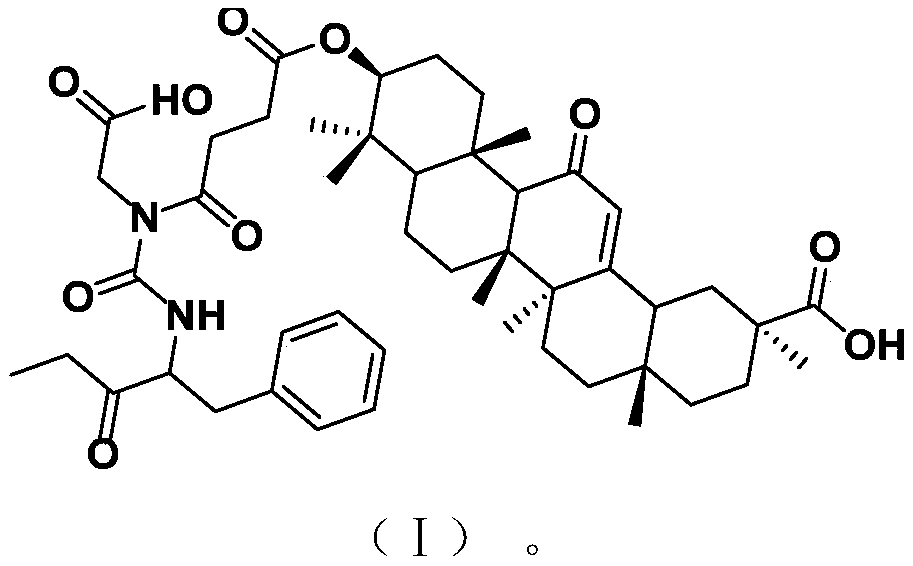

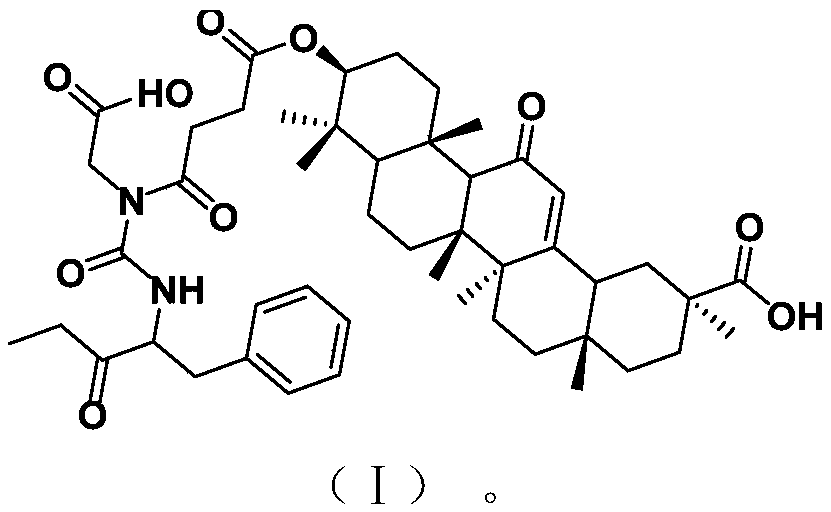

[0025] A kind of glycyrrhetinic acid derivative ASBT of the present invention has the structure shown in general formula I:

[0026]

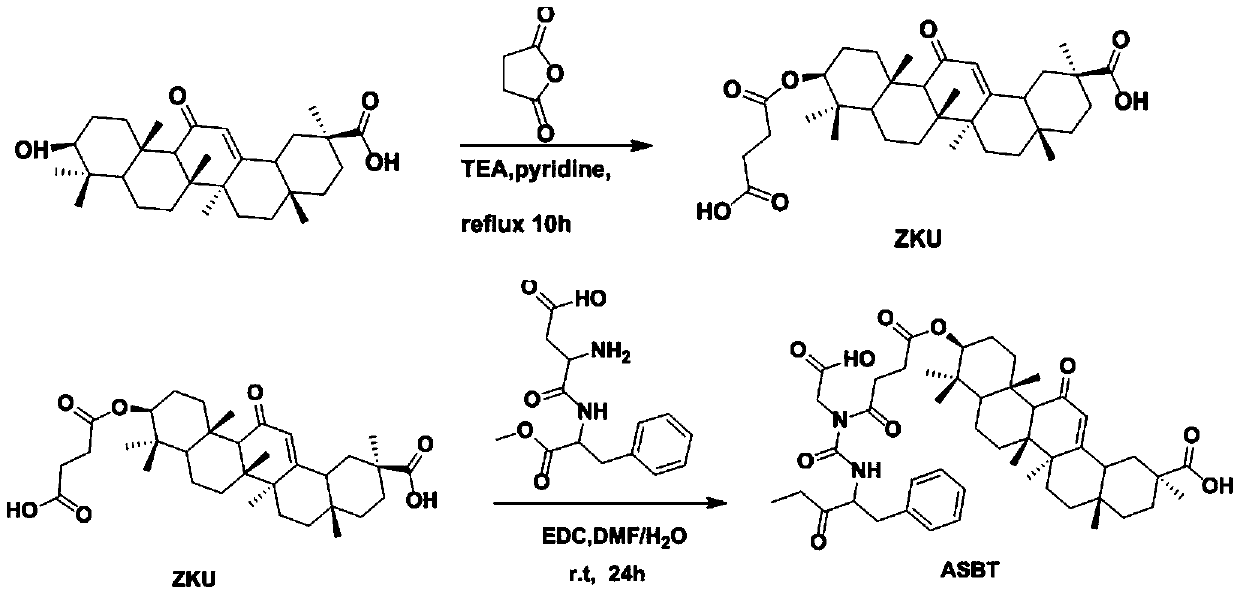

[0027] The preparation method of glycyrrhetinic acid derivative ASBT of the present invention comprises the following steps:

[0028]

[0029] (1) Dissolve glycyrrhetinic acid and succinic anhydride in triethylamine, reflux for 14 hours, after the reaction is completed, dilute with cold water, adjust the pH value of the system to 4 with hydrochloric acid, filter to obtain a brown-black solid, wash the precipitate with hot water, and column layer Analyze and isolate the product to obtain the acidified ZKU of pale yellow solid glycyrrhetinic acid; the molar ratio of glycyrrhetinic acid to succinic anhydride is 1:4. The molar volume ratio of glycyrrhetinic acid to triethylamine is 1:10mol / l, and the volume ratio of triethylamine to cold water is 1:6. In the column chromatography, the volume ratio of ethanol to ethyl acetate is 10:3.

[003...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is:

[0034] In step (1), dissolve glycyrrhetinic acid and succinic anhydride in triethylamine, reflux for 15 hours, after the reaction is completed, dilute with cold water, adjust the pH value of the system to 3 with hydrochloric acid, filter to obtain a brown-black solid, wash with hot water Precipitate, and separate the product by column chromatography to obtain ZKU, an acidified product of glycyrrhetinic acid as a pale yellow solid.

[0035] In step (2), dissolve aspartame in distilled water to prepare a mixed solution, dissolve the acidified ZKU of glycyrrhetinic acid in 30ml of dimethylformamide and add it dropwise to the mixed solution, then 1-ethyl -(3-Dimethylaminopropyl)carbodiimide hydrochloride was added dropwise to the above system, and reacted at 65°C for 25h. The precipitate was washed to obtain the glycyrrhetinic acid derivative ASBT.

[0036] The application of the glycyrrhetinic acid derivative ASB...

Embodiment 3

[0038] The difference between embodiment 3 and embodiment 1 is:

[0039] In step (1), glycyrrhetinic acid and succinic anhydride are dissolved in triethylamine, refluxed for 14-15h, after the reaction is completed, dilute with cold water, adjust the pH value of the system to 3.5 with hydrochloric acid, filter to obtain a brown-black solid, heat The precipitate was washed with water, and the product was separated by column chromatography to obtain ZKU, an acidified compound of glycyrrhetinic acid as a pale yellow solid.

[0040] In step (2), dissolve aspartame in distilled water to prepare a mixed solution, dissolve the acidified ZKU of glycyrrhetinic acid in 30ml of dimethylformamide and add it dropwise to the mixed solution, then 1-ethyl -(3-Dimethylaminopropyl)carbodiimide hydrochloride was added dropwise to the above system, and reacted at 60°C for 30h. The precipitate was washed to obtain the glycyrrhetinic acid derivative ASBT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com