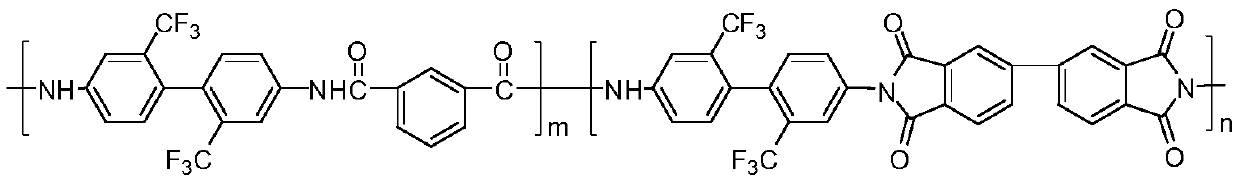

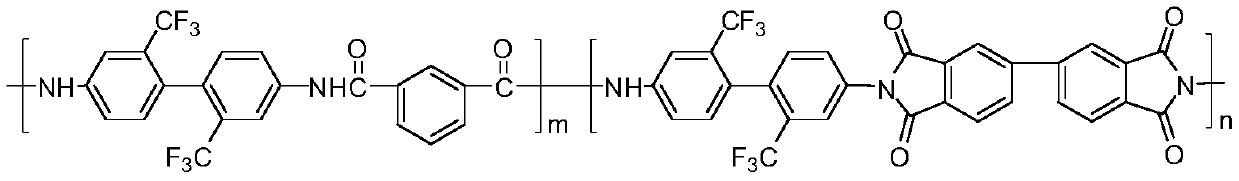

Thermoplastic polyimide resin with low thermal expansion coefficient and preparation method thereof

A technology of polyimide resin and low thermal expansion coefficient, which is applied in the field of thermoplastic polyimide resin with low thermal expansion coefficient and its preparation, can solve the problems of complex preparation process, solvent corrosion resistance, degradation of hydrolysis resistance, etc. Improve the effect of thermoplastic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

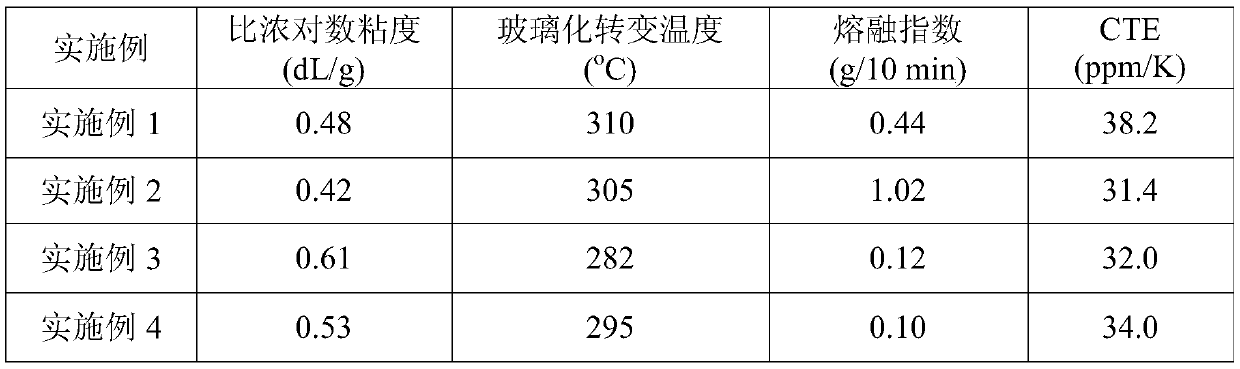

Embodiment 1

[0031] The preparation method (add catalyst) of low coefficient of thermal expansion thermoplastic polyimide resin is as follows:

[0032] Under the protection of nitrogen, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl (9.6072g, 30.0mmol) and 25mL of N,N-dimethylacetamide to the reaction flask at room temperature Stir to dissolve, then add trimethylchlorosilane (3.2592g, 30.0mmol), pyridine (2.1350g, 27.0mmol) and 4-dimethylaminopyridine (0.3665g, 3.0mmol), stir at room temperature for 15 minutes, then cool to 0 ℃, add isophthaloyl dichloride (4.0929, 20.16mmol) and 4,4-biphenyldianhydride (2.5420g, 8.64mmol), then add 25mL of N,N-dimethylacetamide, naturally warm to room temperature, Stir for 12 hours, then add phthalic anhydride (0.3554g, 2.4mmol) to cap, continue to react for 2 hours, then add a mixture of acetic anhydride (120mmol) and pyridine (60mmol), and react at 80°C for 2 hours. Drop the reaction solution into ethanol to obtain fibrous polyimide precipitates, and...

Embodiment 2

[0034] The preparation method (do not add catalyst) of low coefficient of thermal expansion thermoplastic polyimide resin is as follows:

[0035]Under the protection of nitrogen, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl (9.6072g, 30.0mmol) and 25mL of N,N-dimethylacetamide to the reaction flask at room temperature Stir to dissolve, then cool to 0°C, add isophthaloyl dichloride (4.0929, 20.16mmol) and 4,4-biphenyldianhydride (2.5420g, 8.64mmol), add 25mL of N,N-dimethylethane Amide, naturally warmed to room temperature, stirred for 12 hours, then added phthalic anhydride (0.3554g, 2.4mmol) capping, continued to react for 2 hours, then added a mixture of acetic anhydride (120mmol) and pyridine (60mmol), and reacted at 80°C for 2 hours. Hour. Drop the reaction solution into ethanol to obtain fibrous polyimide precipitates, and dry to obtain polyimide powder. See Table 1 for performance measurements.

Embodiment 3

[0037] Under the protection of nitrogen, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl (9.6072g, 30.0mmol) and 25mL of N,N-dimethylacetamide to the reaction flask at room temperature Stir to dissolve, then add trimethylchlorosilane (3.2592g, 30.0mmol), pyridine (2.1350g, 27.0mmol) and 4-dimethylaminopyridine (0.3665g, 3.0mmol), stir at room temperature for 15 minutes, then cool to 0 ℃, add isophthaloyl dichloride (1.7542g, 8.64mmol) and 4,4-biphenyl dianhydride (5.9315g, 20.16mmol), add 25mL of N,N-dimethylacetamide, naturally warm to room temperature , stirred for 12 hours, then added phthalic anhydride (0.3554g, 2.4mmol) to block, continued the reaction for 2 hours, then added a mixture of acetic anhydride (120mmol) and pyridine (60mmol), and reacted at 80°C for 2 hours. Drop the reaction solution into ethanol to obtain fibrous polyimide precipitates, and dry to obtain polyimide powder. See Table 1 for performance measurements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com