A method for producing short-medium-chain polyhydroxyalkanoate pha and functional derivatives thereof

A technology of chain polyhydroxyalkanoates and derivatives, which is applied in the fields of biotechnology and materials, can solve the problems of large consumption, incompleteness, and easy contamination of bacteria, and achieves the effect of low energy consumption and no need for sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The preparation method of the seed liquid in the following examples is as follows: 1) strain activation: get the strain glycerol tube stored in the -80°C refrigerator, and inoculate it into the 60-LB medium containing 25mg / L chloramphenicol plate, cultured at 37°C for 24-36h. 2) First-class seeds: Pick a single colony from the plate that completed step 1, inoculate it in 20 mL of liquid 60-LB medium containing 25 mg / L chloramphenicol, and culture it with shaking at 37°C and 200 rpm for 24 hours. 3) Secondary seed: Take the primary seed liquid obtained in step 2, inoculate it into 20 mL liquid 60-LB medium containing 25 mg / L chloramphenicol according to the inoculum size of 1%, and culture it with shaking at 37° C. and 200 rpm for 8-10 hours.

[0093] The fermentation culture method in the following examples is specifically as follows: 1) Preparation of seed liquid: refer to the preparation method of the above-mentioned seed liquid. 2) Preparation of fermentation medium...

Embodiment 1

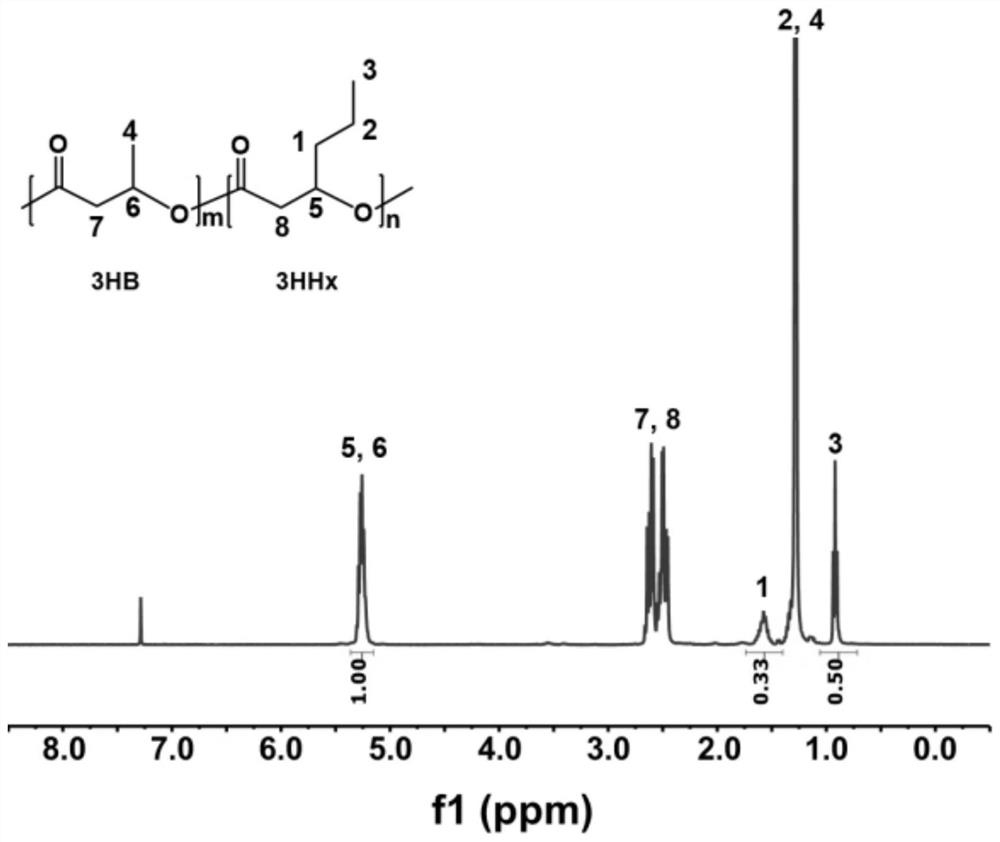

[0105] Example 1. Controllable production of short and medium chain PHA [P(3HB-co-3HHx)] using recombinant Halomonas

[0106] 1. Construction of Recombinant Halomonas

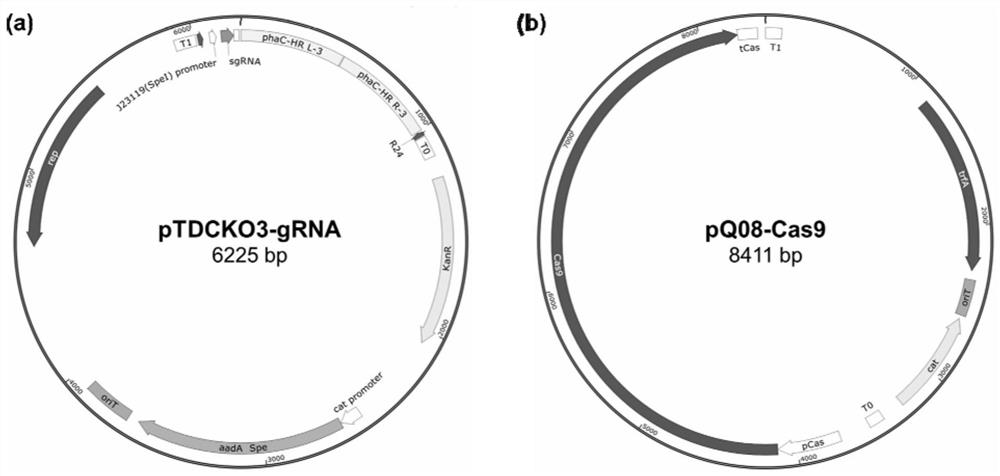

[0107] 1. Construction of endogenous phaC gene-deficient strain H. bluephagenesis TDCKO3

[0108] 1) Extract the genomic DNA of Halomonas H. bluephagenesis TD01, and use it as a template to clone homologous fragments phaC-HR-L-3 and phaC-HR-R-3 with a length of 500 bp, respectively. It is located upstream and downstream of the phaC gene of H. bluephagenesis TD01.

[0109] 2) Using pQ31 (construct the backbone plasmid for CRISPR / Cas9 knockout gRNA [Qin, Q., Ling, C., Zhao, Y.Q., Yang, T., Yin, J., Guo, Y.Y., and Chen, G.Q. (2018) CRISPR / Cas9 editing genome of extremophile Halomonas spp., Metab.Eng.47, 219-229.]) as a template, the two homologous fragments and the backbone fragment of pQ31 were amplified by PCR, and constructed by One-spot method pTDCKO3-donor plasmid, based on the correct pTDCKO3-donor plasmi...

Embodiment 2

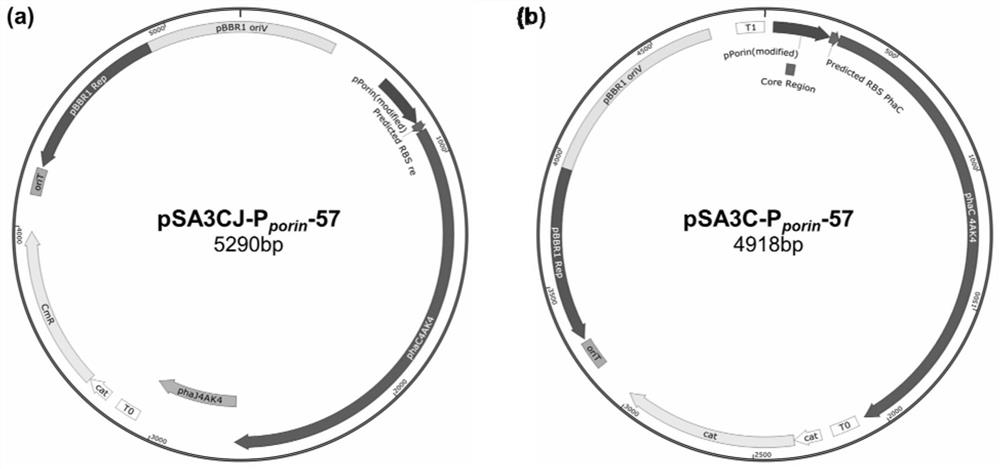

[0162] Example 2. Controllable production of short and medium chain functional PHA [P(3HB-co-3HHxE)] using recombinant Halomonas

[0163] 1. Preparation of recombinant Halomonas H. bluephagenesis TDCKO3 (pSA3CJ-P porin -57) seed solution.

[0164] 2. Fermentation with glucose and different concentrations of hexenoic acid as dual carbon sources

[0165] Get 2.5mL of the recombinant Halomonas H.bluephagenesis TDCKO3 (pSA3CJ-P porin -57) Seed solution, inoculated in a 500 mL shake flask containing 47.5 mL of shake flask culture medium, cultured with shaking at 37° C. and 200 rpm for 48 hours.

[0166] Shake flask medium is any of the following:

[0167] Shake flask medium 10G+0.25HEA: 60-MM medium containing 25mg / L chloramphenicol, 10g / L glucose and 0.25g / L 5-hexenoic acid;

[0168] Shake flask medium 10G+0.5HEA: 60-MM medium containing 25mg / L chloramphenicol, 10g / L glucose and 0.5g / L 5-hexenoic acid;

[0169] Shake flask medium 10G+1HEA: 60-MM medium containing 25mg / L chlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com