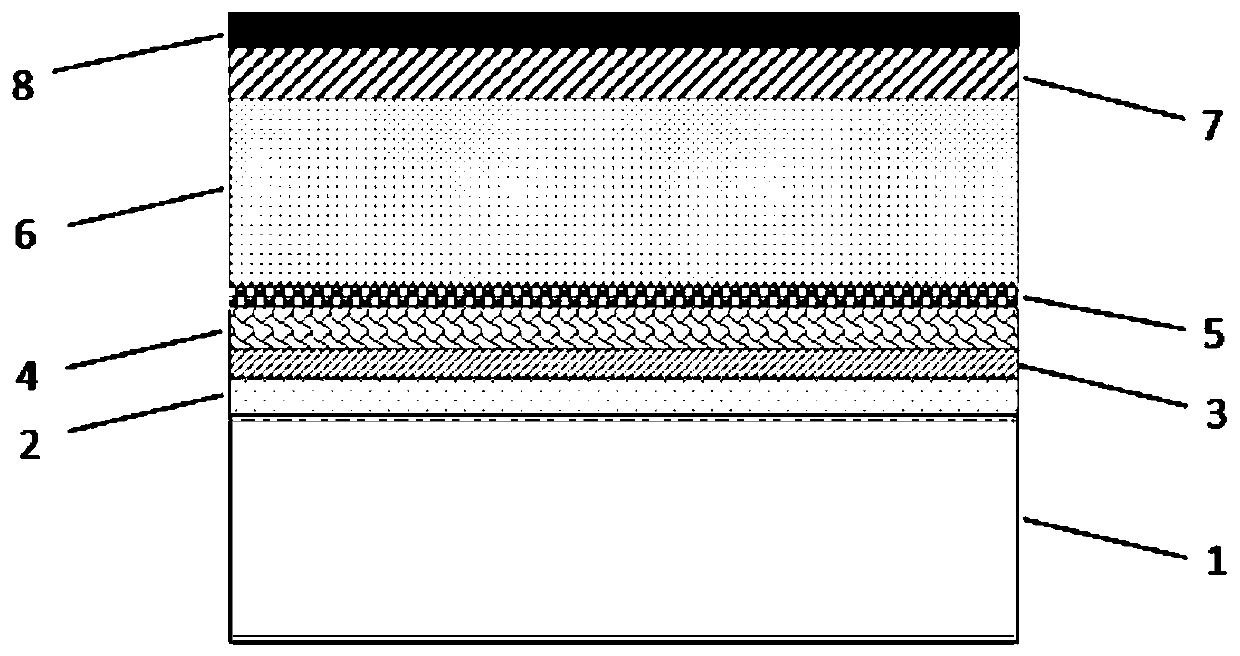

Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of insufficient light absorption in the active layer, easy reaction, battery temperature rise, etc., and achieve the effect of increasing light absorption efficiency, improving efficiency, and increasing numerical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

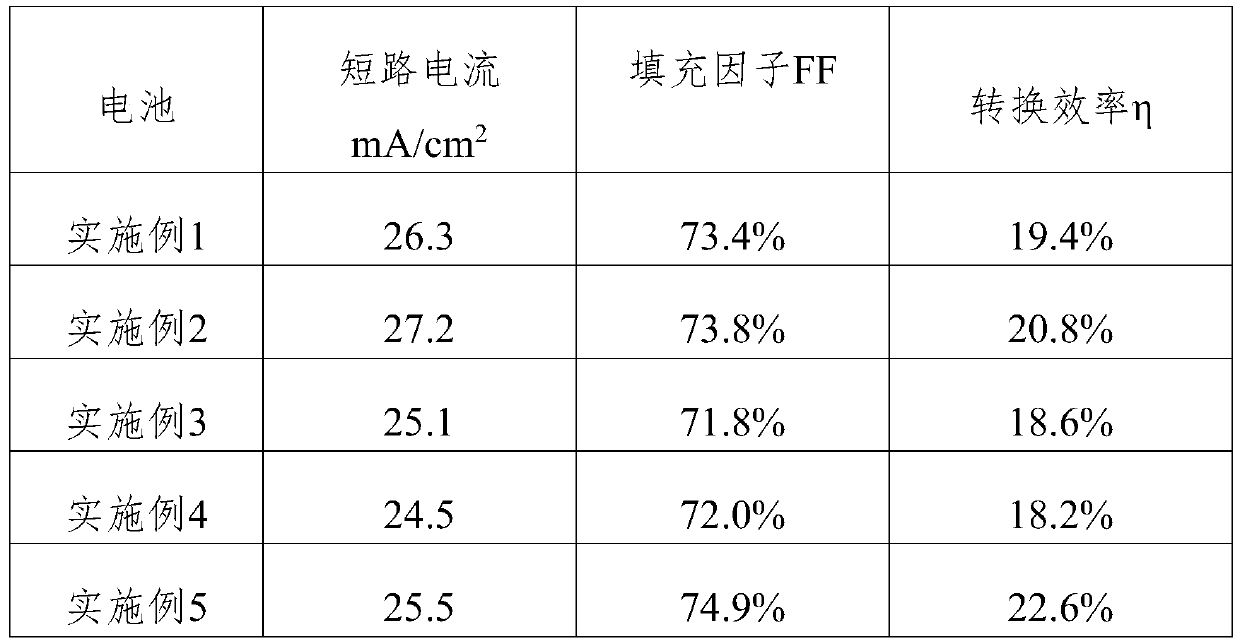

Embodiment 1

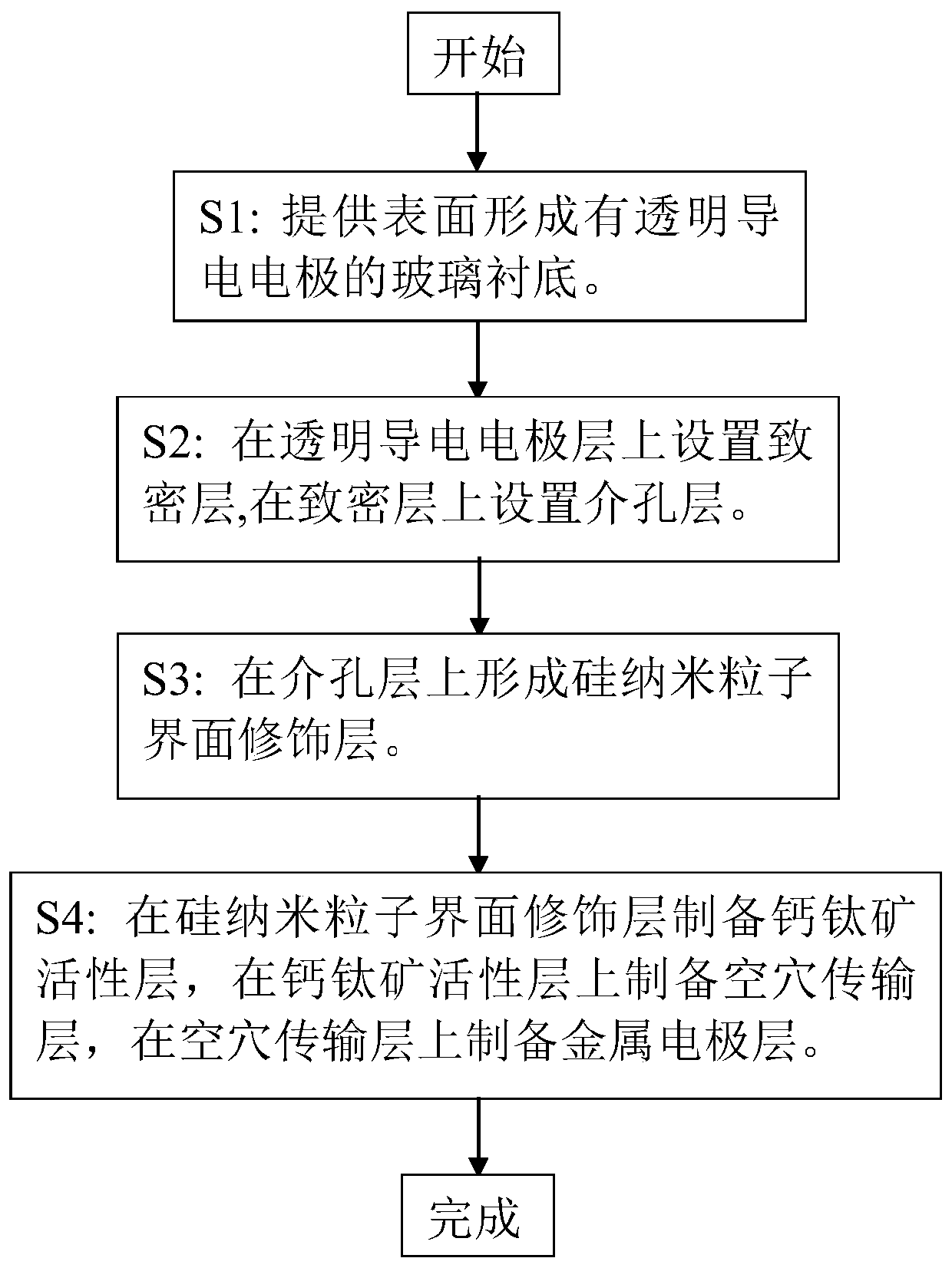

[0069] according to figure 2 The flow chart of the preparation method is shown to prepare the perovskite solar cell of this embodiment.

[0070] S1: Acetone, deionized water, and isopropanol were used to ultrasonically clean the glass substrate with the transparent conductive electrode ITO in sequence.

[0071] S2: sequentially prepare 80 nm dense layer TiO on the ITO electrode 2 , 300 nm mesoporous TiO 2 , and dried and sintered at 450°C.

[0072] S3: The preparation concentration is 1.5×10 -9 mol / L silicon nanoparticle / toluene suspension, wherein the silicon nanoparticle used is spherical, with an average diameter of 150 nanometers; then the silicon nanoparticle / toluene suspension is spin-coated on the mesoporous layer by spin coating , dried at 70°C for 10 minutes; then spin-coated the silicon nanoparticle / toluene suspension solution again, dried at 70°C for 10 minutes, and repeated this cycle for 3 times, and finally dried at 80°C for 50 minutes. The thickness of the...

Embodiment 2

[0075] according to figure 2 The flow chart of the preparation method is shown to prepare the perovskite solar cell of this embodiment.

[0076] S1: Acetone, deionized water, and isopropanol were used to ultrasonically clean the glass substrate with the transparent conductive electrode ITO in sequence.

[0077] S2: sequentially prepare a 100 nm dense layer of TiO on the ITO electrode 2 , 400 nm mesoporous TiO 2 , and dried and sintered at 450°C.

[0078] S3: The preparation concentration is 1×10 -9 mol / L silicon nanoparticle / toluene suspension, wherein the silicon nanoparticle used is spherical and has an average diameter of 120 nanometers; then the silicon nanoparticle / toluene suspension is spin-coated on the mesoporous layer by spin coating , dried at 80°C for 10 minutes; then spin-coated the silicon nanoparticle / toluene suspension solution again, dried at 80°C for 10 minutes, repeated 5 times in this way, and finally dried at 80°C for 60 minutes, the prepared silicon ...

Embodiment 3

[0081] according to figure 2 The flow chart of the preparation method is shown to prepare the perovskite solar cell of this embodiment.

[0082] S1: Acetone, deionized water, and isopropanol are used to ultrasonically clean the glass substrate with the transparent conductive electrode FTO in sequence.

[0083] S2: Sequentially prepare a 50 nm dense layer of TiO on the FTO electrode 2 , 200 nm mesoporous TiO 2 / ZrO 2 , and dried and sintered at 450°C.

[0084] S3: The preparation concentration is 2×10 -9 mol / L silicon nanoparticle / toluene suspension, wherein the silicon nanoparticle used is spherical, with an average diameter of 80 nanometers; then the silicon nanoparticle / toluene suspension is spin-coated on the mesoporous layer by spin coating , dried at 50°C for 10 minutes; then spin-coated silicon nanoparticles / toluene suspension solution again, dried at 50°C for 10 minutes, and cycled 5 times, and finally dried at 80°C for 30 minutes, the prepared silicon The thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap