Composite coating diaphragm with uniform pore size and preparation method thereof

A composite coating and coating technology, which is applied to structural parts, electrical components, battery pack parts, etc., can solve the problems of increasing the volume and quality of the diaphragm, reducing the energy density of the battery, and decreasing the electrical performance of the battery, so as to improve the cycle life and charge and discharge efficiency, reduce battery internal resistance, and improve heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

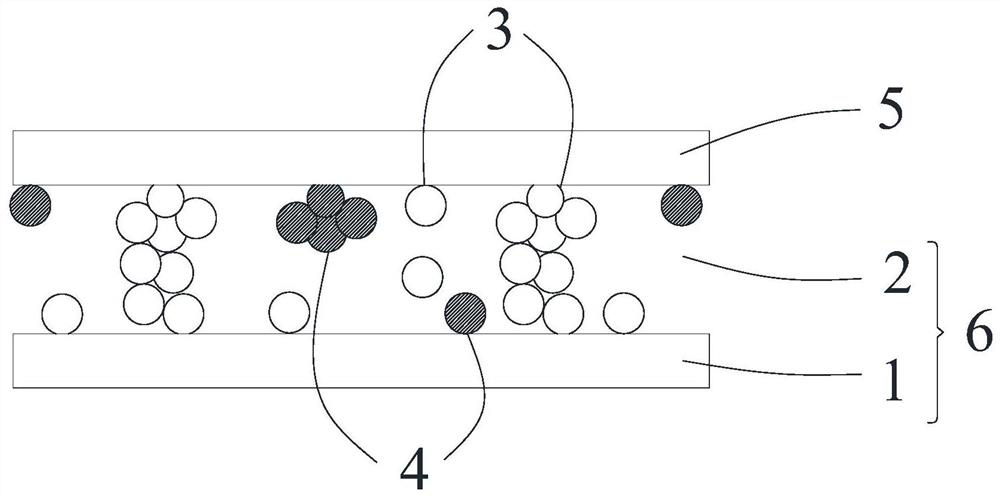

[0023] See figure 1 , the present embodiment 1 provides a composite coated diaphragm, comprising: a base film 1 and a composite coating 2 coated on the surface of the base film; and the composite coating 2 contains polymer composite particles 3 and a ceramic composite Particles 4, so that the pore size of the micropores in the composite coating 2 is consistent with that of the base film 1.

[0024] Optionally, the mass ratio of the polymer composite particles 3 to the ceramic composite particles 4 is 1:(0.5-20), optionally 1:5 or 1:10.

[0025] Optionally, the base film 1 includes a polypropylene film, a polyethylene film or a multilayer composite film of the two; and the base film contains micropores with a pore size of 0.01 μm-0.8 μm.

[0026] Optionally, the polymer composite particles 3 include: polymer particles of at least two particle sizes, the particle size ranges are 0.1 μm-4 μm and 4-8 μm respectively; and the mass ratio of the two is 1:(0.1-10 ). The polymer com...

Embodiment 2

[0030] like figure 2 As shown, on the basis of Example 1, this Example 2 also provides a method for preparing a composite coating separator, including: preparing a composite coating slurry; coating the composite coating slurry on the surface of the base film; and drying to obtain a composite coated separator.

[0031] Specifically, the composite coating slurry includes the following raw materials in parts by mass: deionized water: 50-95 parts; polymer composite particles: 1-40 parts; ceramic composite particles: 1-45 parts; binder: 1-20 parts; dispersant: 0.1-25 parts; wetting agent: 0.1-15 parts; stabilizer: 0.5-30 parts; and other additives: 0.1-10 parts.

[0032] Optionally, the composite coating slurry includes the following raw materials in parts by mass: deionized water: 80 parts; polymer composite particles: 20 parts; ceramic composite particles: 25 parts; binder: 15 parts; dispersant : 5 parts; wetting agent: 12 parts; stabilizer: 20 parts; and other additives: 8 pa...

Embodiment 3

[0037] 65 parts of deionized water, 0.91 parts of the first polymer particles, 0.19 parts of the second polymer particles, 3.64 parts of the first ceramic particles, 0.36 parts of the second ceramic particles, 4 parts of binders, 3 parts of dispersants, 2 parts Wetting agent, 3 parts of stabilizer, and 3 parts of other additives are mixed uniformly to prepare composite coating slurry.

[0038] The particle size of the first polymer particle is 0.1 μm, the particle size of the second polymer particle is 4 μm, the mass ratio of the two is 1:0.1, the initial particle size of the polymer is 0.1-0.5 μm; the particle size of the first ceramic particle is 0.1 μm, The particle size of the second ceramic particles is 0.6 μm, and the ratio thereof is 1:0.1; wherein, the mass ratio of the polymer particles to the ceramic particles is 1:4.

[0039]The polyethylene film was used as the substrate, and the composite coating slurry was coated by a top coating process, wherein the top coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com