Preparation of antibacterial agent based on MXene quantum dots and antibacterial activity testing method

An antibacterial agent and quantum dot technology, which is applied in the field of semiconductor materials and antibacterial applications, can solve the problems of easy discoloration, difficult manufacturing, complex process, etc., and achieve the effect of simple preparation method, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

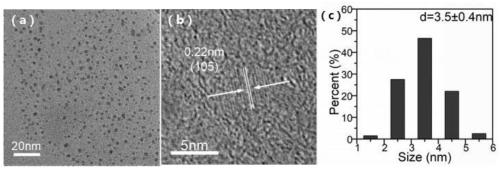

Embodiment 1

[0031] Electrochemical preparation of Ti 3 C 2 QDs as an example, specifically: using bulk commercial Ti 3 AlC 2 As the working electrode, platinum wire as the counter electrode, tetramethylammonium hydroxide (TMA OH) and NH 4 Cl solution was mixed as electrolyte, and MQDs were prepared by two-electrode system constant potential method using CHI 660D electrochemical workstation; the scanning voltage and scanning time were 0.1V and 1h, respectively; the prepared electrolyte was centrifuged at 8000r / min for 15 minutes, Get the supernatant and centrifuge again, repeat several times until there is no precipitation in the solution; the solution is filtered with a 220nm aqueous polyethersulfone syringe filter and continuously dialyzed with a 21mm (MD25) dialysis bag for 3 days to obtain an aqueous solution of MQDs (0.12mg / mL).

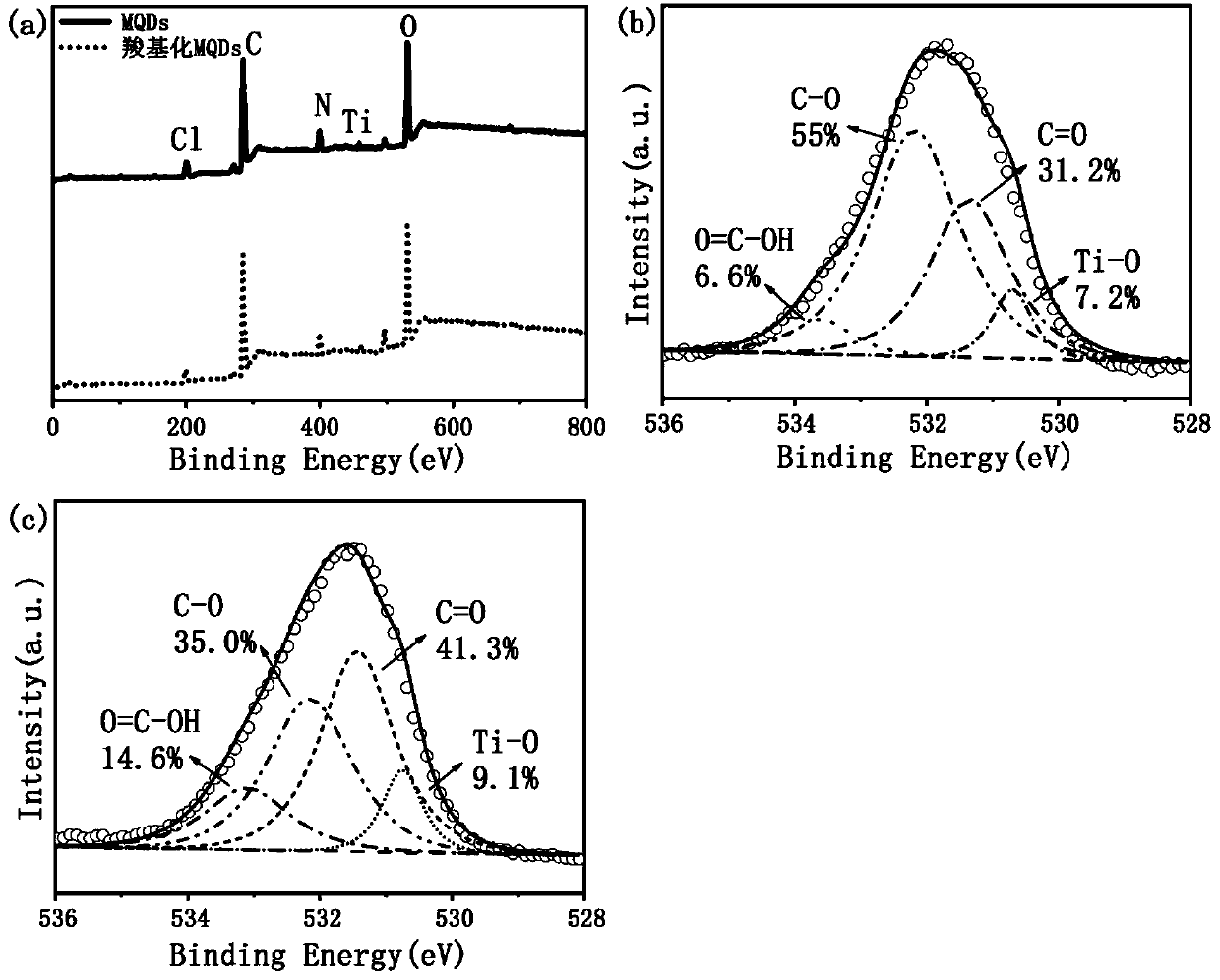

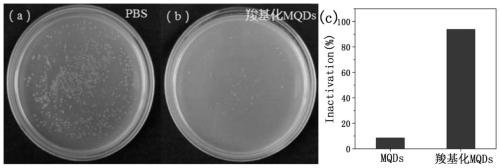

[0032] Then UV / H was applied to the prepared MQDs 2 o 2 Control and prepare carboxylated MQDs, specifically: pour 4 mL of MQDs solution into a 10 mL ...

Embodiment 2

[0039] Preparation of Ti by Electrochemical Method 3 C 2 QDs, specifically: MQDs prepared by a two-electrode system potentiostatic method; bulk commercial Ti 3 AlC 2 As the working electrode, platinum wire as the counter electrode, tetramethylammonium hydroxide (TMA OH) and NH 4 The Cl solution was mixed into an electrolyte, using a CHI 660D electrochemical workstation; the scanning voltage and scanning time were 0.2V and 30 minutes, respectively; the prepared electrolyte was centrifuged at 9000r / min for 5 minutes, the supernatant was taken and centrifuged again, and repeated After several times until there was no precipitation in the solution; the solution was filtered with a 220nm aqueous polyethersulfone syringe filter and continuously dialyzed with a 21mm (MD25) dialysis bag for 3 days to obtain an aqueous solution of MQDs (0.12mg / mL).

[0040] UV / H on the prepared MQDs 2 o 2 Control and prepare carboxylated MQDs, specifically: pour 4 mL of MQDs solution into a 10 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com