A pressurized fluid extraction system and method for removing metal ions from carbon materials

A technology of pressurized fluid and metal ions, applied in the direction of material excitation analysis, solid solvent extraction, preparation of test samples, etc., can solve the problem of using a large amount of removal effect, achieve the effect of improving efficiency and reducing the number of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

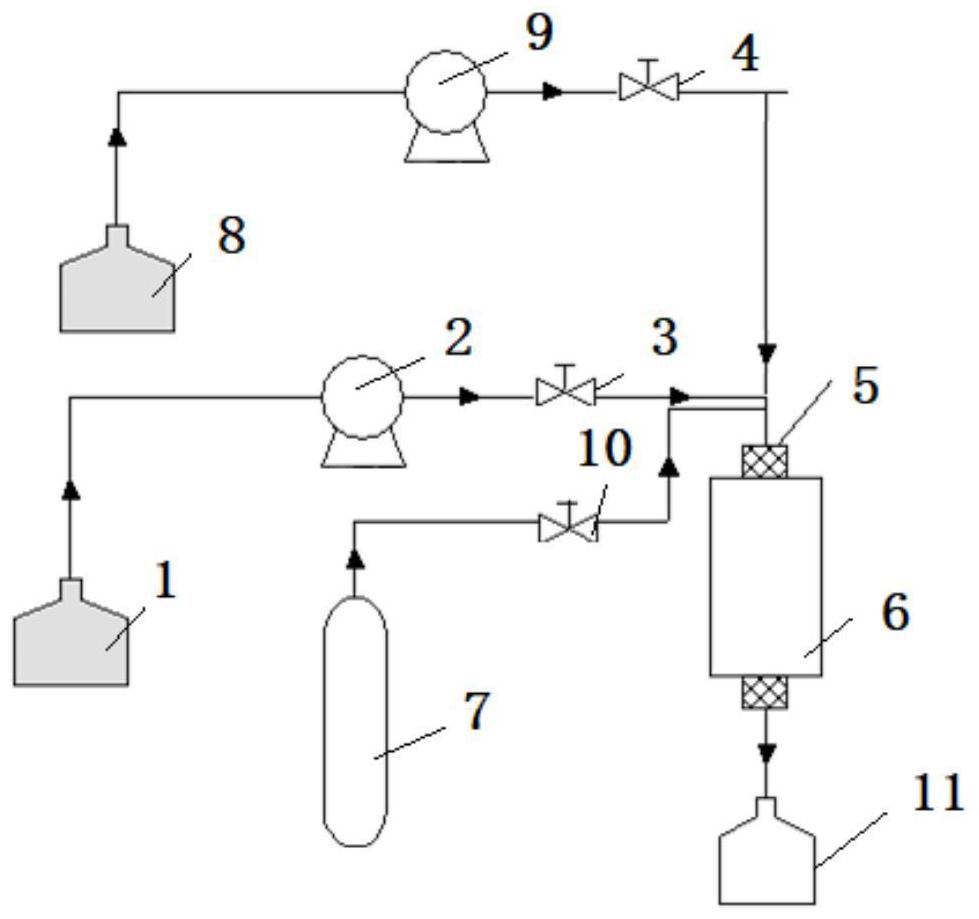

Method used

Image

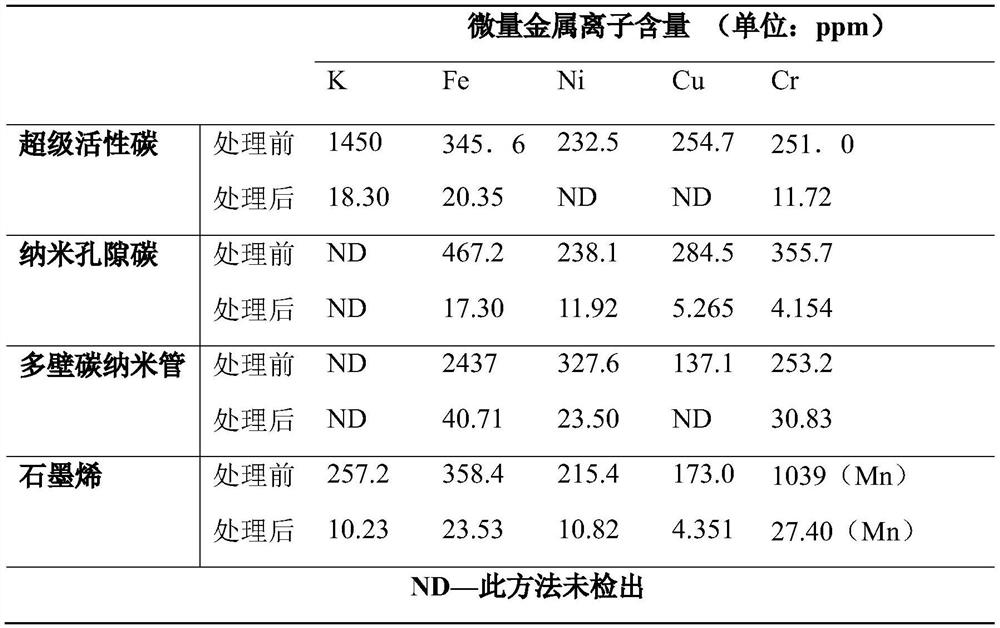

Examples

Embodiment 1

[0051] Step 1. The carbon material raw material is pre-oxidized in air at 420°C for 10 minutes, and cooled to room temperature in nitrogen;

[0052] Step 2, 100 grams of pre-oxidized carbon material raw material and 150 mesh quartz sand are mixed according to the mass ratio of 1:1, and then put into the pressurized fluid extraction pipe 5;

[0053] Step 3. Heat the extraction unit to 100°C. The first pressurized pump 2 injects the eluent 1 into the extraction unit at a working pressure of 5.0 MPa. The time for a single pressurized extraction is 10 minutes, and the eluent is injected 5 times in 1 minute. In extraction tube 5;

[0054] Step 4, the eluent 1 is a polyacrylic acid solution with a concentration of 0.5wt%, and the average molecular weight of polyacrylic acid is 3000. The extracted unit after treatment is injected with deionized water under the same working conditions as in step 3, and the single cleaning time The cleaning time is 8 minutes, and the cleaning times ar...

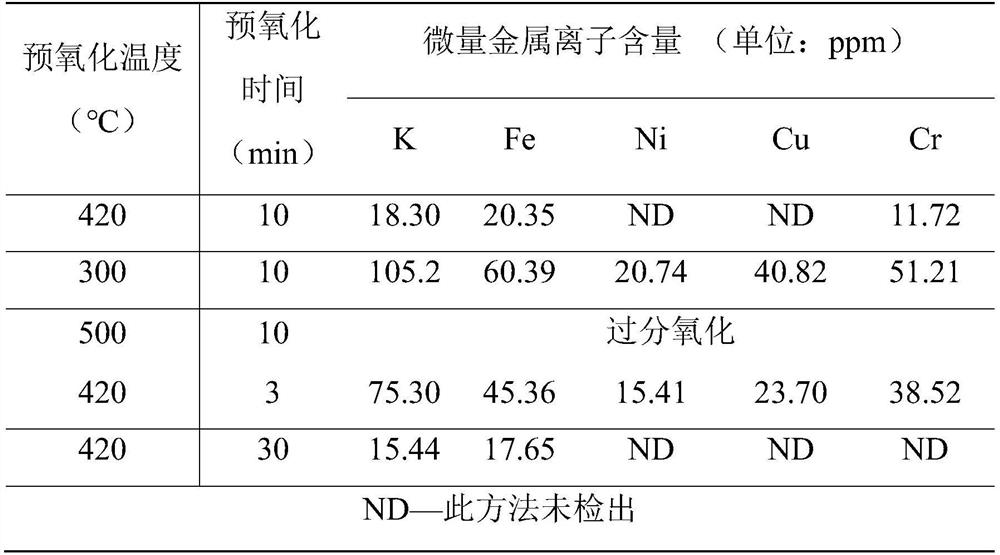

Embodiment 2

[0059] Step 1, the activated carbon sample is pre-oxidized by heating in air (treatment conditions are as shown in Table 2), and cooled to room temperature in nitrogen;

[0060] Step 2. Mix 100 grams of pre-oxidized carbon material raw materials with 150 mesh quartz sand in a mass ratio of 1:1 and put them into the pressurized fluid extraction tube 5;

[0061] Step 3. The extraction unit is heated to 100°C, and the first pressurized pump 2 injects the eluent 1 into the extraction unit at a working pressure of 5.0 MPa. The time for a single pressurized extraction is 10 minutes, and the eluent 1 can be pressurized and injected in 5 times ;

[0062] Step 4. The eluent 1 is a polyacrylic acid solution with a concentration of 0.5 wt%, and the average molecular weight of the polyacrylic acid is 3000. The treated extraction unit was injected with deionized water for cleaning under the same working conditions, and the single cleaning time was 8 minutes, and the cleaning times were 3 ...

Embodiment 3

[0067] Step 1. Pre-oxidize the raw materials by heating in air at 420°C for 10 minutes, and cool to room temperature in nitrogen;

[0068] Step 2. Mix 100 grams of pre-oxidized carbon material raw materials with 150 mesh quartz sand at a mass ratio of 1:1 and put them into the pressurized fluid extraction pipe 5 .

[0069] Step 3. The extraction unit is heated to the working temperature, and the first booster pump 2 injects the eluent 1 into the extraction unit according to the working pressure (the extraction operating conditions are shown in Table 3).

[0070] Step 4, the eluent 1 is a polyacrylic acid solution with a concentration of 0.5%, and the average molecular weight of the polyacrylic acid is 3000. The treated extraction unit was injected with deionized water for cleaning under the same working conditions, and the single cleaning time was 8 minutes, and the cleaning times were 3 times. Afterwards, nitrogen gas is introduced to remove the liquid, the solid material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com