Method for efficiently extracting longan seed polyphenols

A longan core and high-efficiency technology, applied in food extraction, medical preparations containing active ingredients, pharmaceutical formulations, etc., can solve the problems of high energy consumption, long time consumption of polyphenols, low extraction rate, etc. The effect of improving efficiency, improving purity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

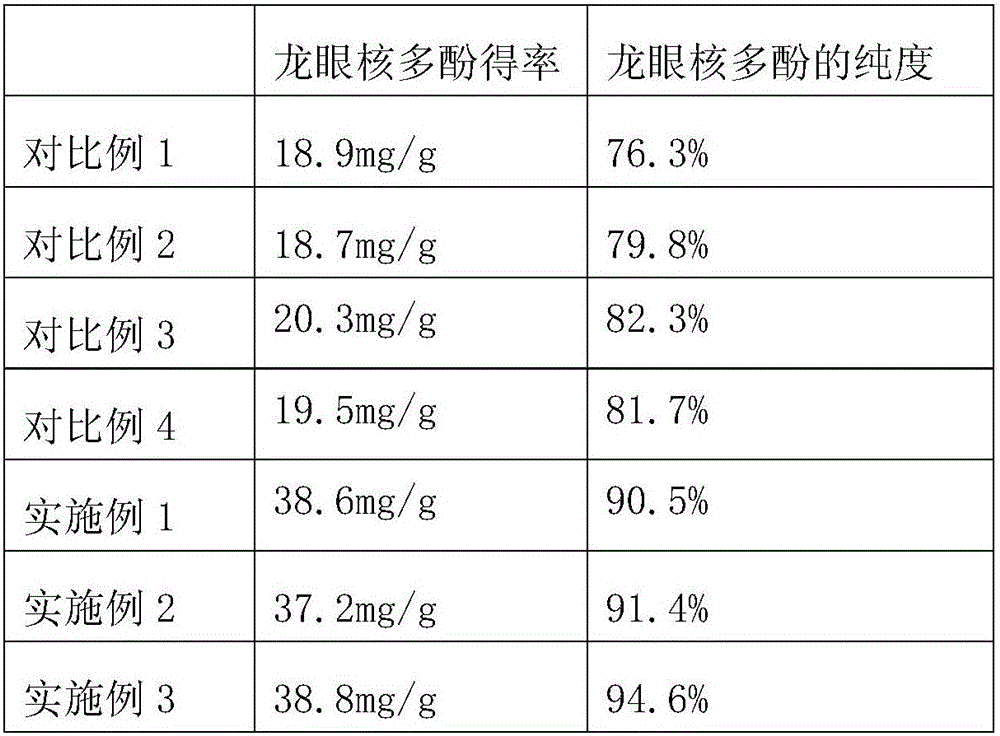

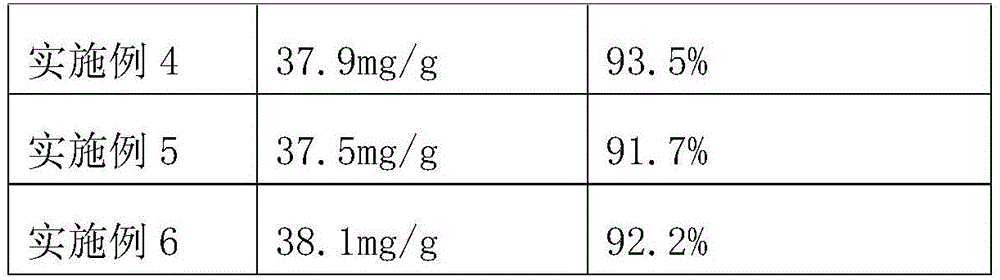

Examples

Embodiment 1

[0047] 1. Preliminary preparation:

[0048] Preparation of compound enzyme accelerator: mix 10g polygalacturonase, 20g pectin lyase, 5g cellulase, 10g pectin esterase, 8g Rhizopus oligosporus and 10g laccase, add 5g twelve Sodium alkylbenzene sulfonate and 80 g of purified water were used to adjust the pH value to 5.5, and shaken in a water bath at a speed of 100 r / min at 25° C. for 18 hours to obtain a compound enzyme accelerator.

[0049] Preparation of dichloromethane-chloroform mixed solution: 300 g of chemically pure grade dichloromethane solution and 100 g of chemically pure grade chloroform solution were uniformly mixed to obtain a dichloromethane-chloroform mixed solution.

[0050] The substances prepared above are used in the following method for extracting longan kernel polyphenols.

[0051] 2. A method for efficiently extracting longan kernel polyphenols, comprising the following steps:

[0052] (1) Pulping and radiation treatment: 100g of fresh longan core and 20...

Embodiment 2

[0057] 1. Preliminary preparation:

[0058] Preparation of compound enzyme accelerator: mix 11g polygalacturonase, 25g pectin lyase, 6g cellulase, 12g pectin esterase, 10g Rhizopus oligosporus and 12g laccase, add 6g twelve Sodium alkylbenzene sulfonate, 1g Tween and 85g purified water, adjust the pH value to 6, and shake in a water bath at 28°C for 19h at a speed of 120r / min to obtain a compound enzyme accelerator.

[0059] Preparation of dichloromethane-chloroform mixed solution: 330 g of chemically pure grade dichloromethane solution and 100 g of chemically pure grade chloroform solution were uniformly mixed to obtain a dichloromethane-chloroform mixed solution.

[0060] The substances prepared above are used in the following method for extracting longan kernel polyphenols.

[0061] 2. A method for efficiently extracting longan kernel polyphenols, comprising the following steps:

[0062] (1) Pulping and radiation treatment: 100g of fresh longan core and 260g deionized wat...

Embodiment 3

[0067] 1. Preliminary preparation:

[0068] Preparation of compound enzyme accelerator: mix 13g polygalacturonase, 25g pectin lyase, 7g cellulase, 12g pectin esterase, 10g Rhizopus oligospora and 11g laccase, add 5g lauric acid , 2g of coconut oil fatty acid monoethanolamide and 90g of purified water, adjust the pH value to 5.9, shake in a water bath at 30°C for 20h at a speed of 115r / min, and obtain a compound enzyme accelerator.

[0069] Preparation of dichloromethane-chloroform mixed solution: 340 g of chemically pure grade dichloromethane solution and 100 g of chemically pure grade chloroform solution were uniformly mixed to obtain a dichloromethane-chloroform mixed solution.

[0070] The substances prepared above are used in the following method for extracting longan kernel polyphenols.

[0071]2. A method for efficiently extracting longan kernel polyphenols, comprising the following steps:

[0072] (1) Pulping and radiation treatment: 100g of fresh longan core and 280g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com