ZrO2@SiO2 catalyst with core-shell structure, preparation method and application thereof

A technology of core-shell structure and catalyst, which is applied in the field of core-shell structure ZrO2@SiO2 catalyst and its preparation, and can solve problems such as ignoring catalyst configuration design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

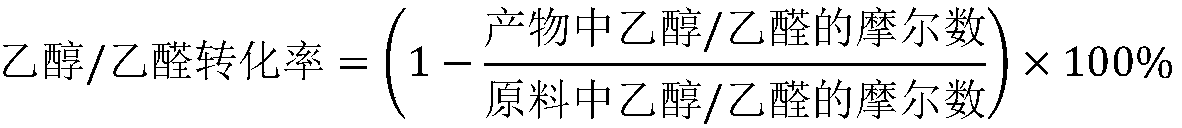

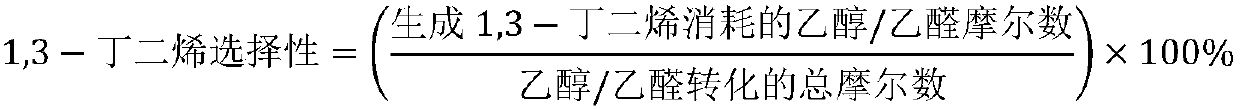

Examples

Embodiment 1

[0091] The preparation of embodiment 1 catalyst

[0092] Weigh 0.2576g of zirconium oxychloride and dissolve it in deionized water, add 8ml of 10mol / L sodium hydroxide solution, and stir evenly. The volume was adjusted to 60 ml with deionized water, and then the solution was transferred to a Teflon-lined autoclave and kept in an oven at 150 °C for 10 h. Naturally cooled to room temperature, the product was collected by centrifugation, washed thoroughly with absolute ethanol and deionized water, and then dispersed into 100ml of absolute ethanol, followed by adding 20ml of deionized water and 6.0g of ammonia water, stirring evenly and adding 6.24g of silicon Acid tetraethyl ester, kept stirring at room temperature for 18 hours, centrifuged to separate the solid product, washed thoroughly with absolute ethanol and deionized water, dried at 70°C, and roasted at 600°C for 3 hours in an air atmosphere to obtain a non-porous shell Silica ZrO 2 @SiO 2 Catalyst, denoted as sample 1 ...

Embodiment 2

[0093] The preparation of embodiment 2 catalyst

[0094]Weigh 0.3432g of zirconium nitrate and dissolve it in deionized water, add 8ml of 10mol / L sodium hydroxide solution, and stir evenly. The volume was adjusted to 60 ml with deionized water, and then the solution was transferred to a Teflon-lined autoclave and kept in an oven at 150 °C for 10 h. Naturally cooled to room temperature, the product was collected by centrifugation, washed thoroughly with absolute ethanol and deionized water, and then dispersed into 100ml of absolute ethanol, followed by adding 20ml of deionized water and 6.0g of ammonia water, stirring evenly and adding 6.24g of silicon Acid tetraethyl ester, kept stirring at room temperature for 18 hours, centrifuged to separate the solid product, washed thoroughly with absolute ethanol and deionized water, dried at 70°C, and roasted at 600°C for 3 hours in an air atmosphere to obtain a non-porous shell Silica ZrO 2 @SiO 2 Catalyst, denoted as sample 2 # . ...

Embodiment 3

[0095] The preparation of embodiment 3 catalyst

[0096] Weigh 0.1864g of zirconyl nitrate and dissolve it in deionized water, add 8ml of 10mol / L sodium hydroxide solution, and stir evenly. The volume was adjusted to 60 ml with deionized water, and then the solution was transferred to a Teflon-lined autoclave and kept in an oven at 150 °C for 10 h. Naturally cooled to room temperature, the product was collected by centrifugation, washed thoroughly with absolute ethanol and deionized water, and then dispersed into 100ml of absolute ethanol, followed by adding 20ml of deionized water and 6.0g of ammonia water, stirring evenly and adding 6.24g of silicon Acid tetraethyl ester, kept stirring at room temperature for 18 hours, centrifuged to separate the solid product, washed thoroughly with absolute ethanol and deionized water, dried at 70°C, and roasted at 600°C for 3 hours in an air atmosphere to obtain a non-porous shell Silica ZrO 2 @SiO 2 Catalyst, denoted as sample 3 # . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com