Composite metal oxide catalyst and application thereof

A composite metal and catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve problems such as shortage and low conversion rate, and achieve large specific surface area , Improve catalytic efficiency, solve the effect of pore blockage and deactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of the present embodiment comprises the following steps:

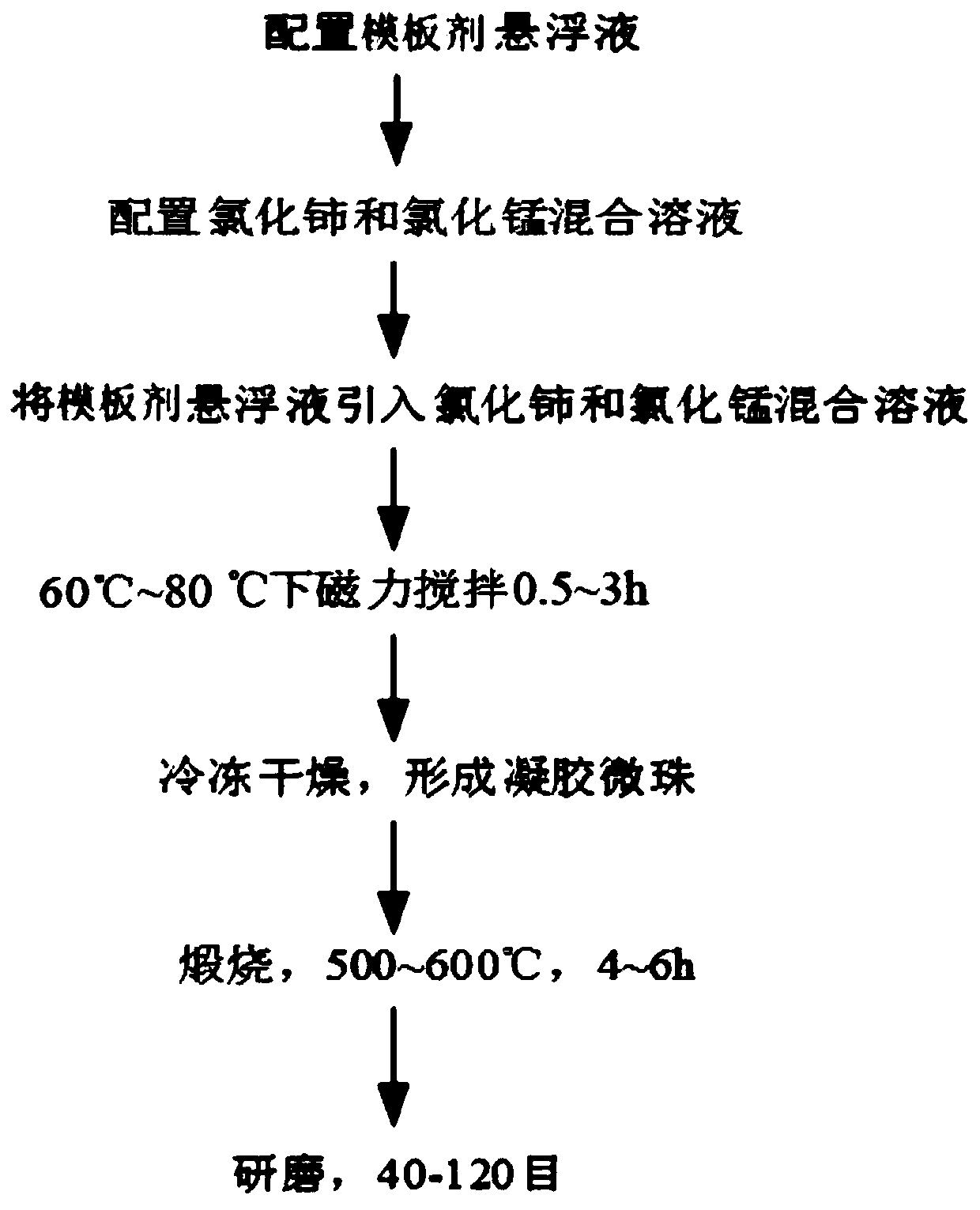

[0047] The preparation of a kind of directional ketosis composite metal oxide catalyst comprises the following steps, as figure 1 Shown:

[0048] (1) Weigh 1.0wt% sodium alginate and 1.0wt% cellulose nanofibers into a beaker, then pour distilled water into the beaker, and configure carbohydrate suspension as a template material;

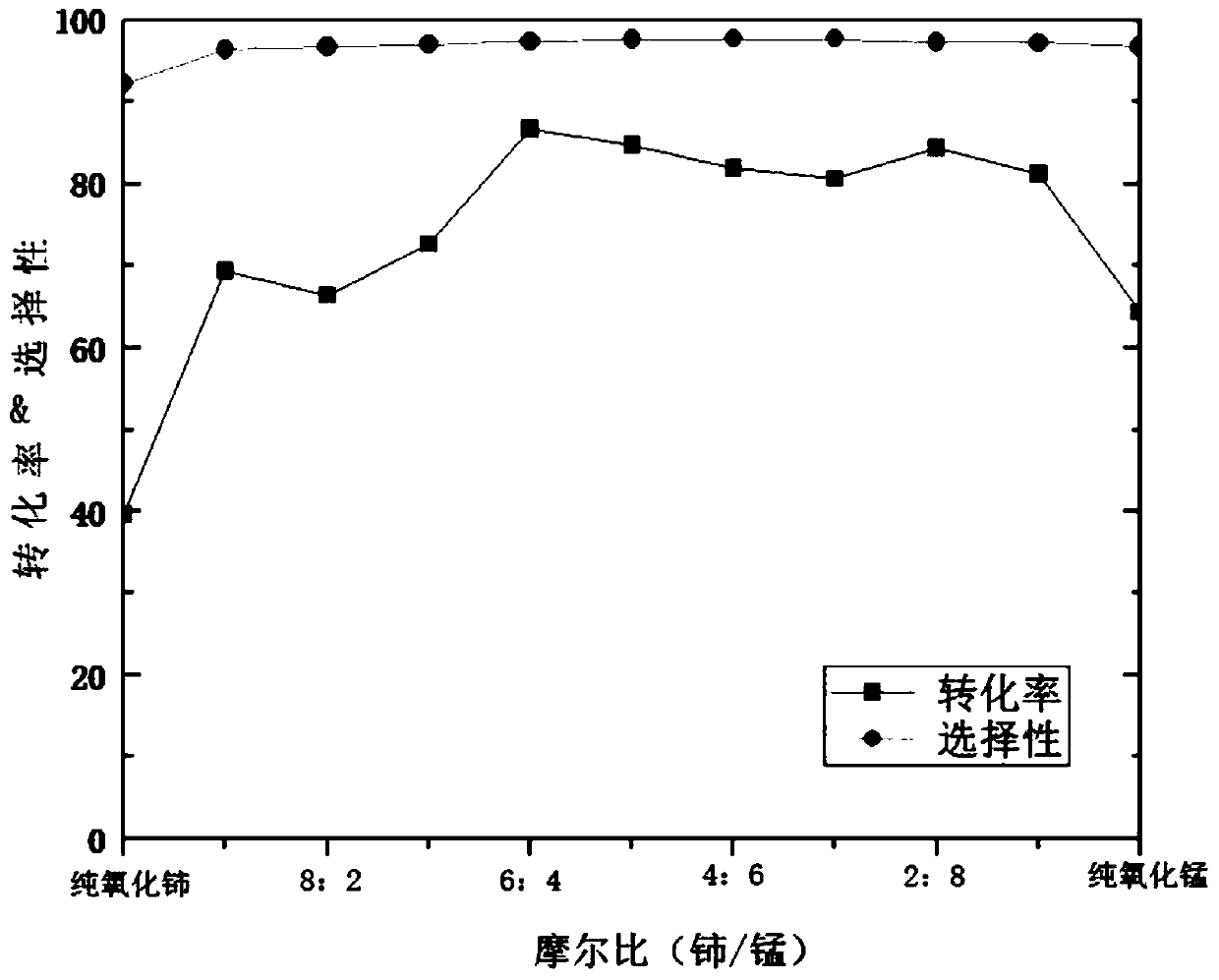

[0049] (2) Weigh a total of 50g of cerium chloride and manganese chloride, put them into a beaker, add 500mL of deionized water, stir to dissolve them completely, and configure a mixed solution of cerium chloride and manganese chloride, in which cerium ions and manganese ions The molar ratio of cerium chloride and manganese chloride is 9:1, and the total molar concentration of cerium chloride and manganese chloride is 10%;

[0050] (3) Use a pipette to introduce the templating agent suspension into the mixed solution of cerium chloride and manganese chloride, w...

Embodiment 2

[0062] The preparation method of the catalyst is the same as in Example 1, except that in the (3) step of the catalyst preparation method, the volume ratio of the templating agent suspension and the cerium-containing manganese ion mixed solution becomes 5:1; in the (4) step, the oil bath temperature In step (5), the freezing temperature is -15°C; in step (6), the calcination temperature is changed to 600°C, and the time is changed to 6 hours. Finally, black catalyst particles are obtained.

[0063] The application process of the catalyst is the same as in Example 1, except that the temperature is changed to 380° C. and the holding time is 3 hours. Finally, a colorless transparent aqueous liquid was obtained.

Embodiment 3

[0065] The preparation method of the catalyst is the same as in Example 1, except that the volume ratio of the templating agent suspension and the cerium-containing manganese ion mixed solution is changed to 3:1 in the step (3); the step (4) of the catalyst preparation method changes the temperature of the oil bath to to 60°C, and the time was changed to 1h; the freezing temperature in step (5) was -10°C, and the calcination temperature in step (6) was changed to 550°C, and the time was changed to 5h. Finally, black catalyst particles are obtained.

[0066] The application process of the catalyst is the same as in Example 1, except that the temperature is changed to 350° C. and the holding time is 1 h. Finally, a colorless transparent aqueous liquid was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com