Waterproof durable light wall material and preparation method thereof

A light-weight wall and durable technology, applied in the field of wall materials, can solve the problems of blocking capillary channels, increasing construction difficulty, sacrificing strength, etc., and achieves the effects of reducing water absorption, water resistance and UV degradation, and improving anti-seepage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

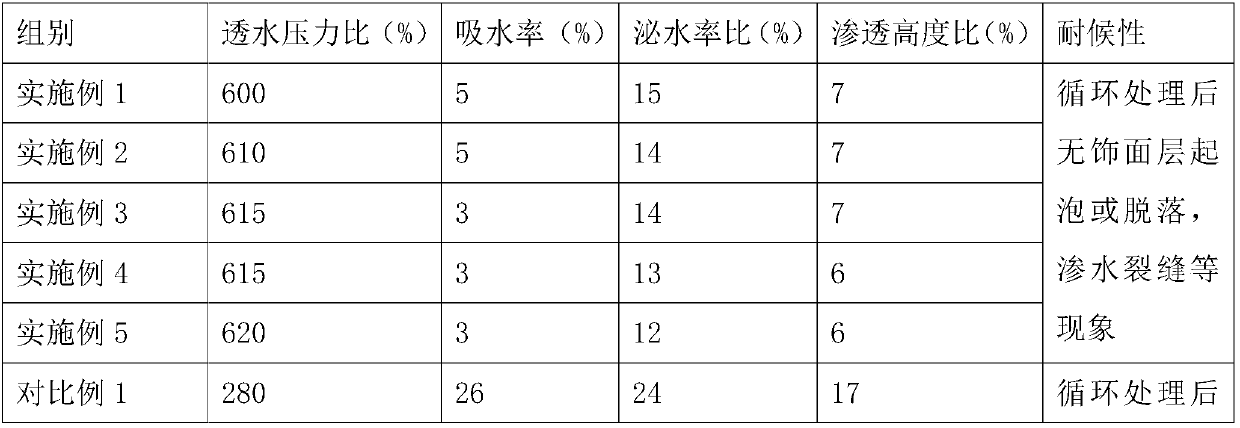

Examples

Embodiment 1

[0022] Composition of raw materials (parts by weight): 50 parts of expanded polystyrene, 25 parts of glass fiber reinforced cement, 15 parts of perlite, 15 parts of slag, 10 parts of yellow sand, 10 parts of clay, 5 parts of diatom mud, organic silicon microcapsules 5 parts of waterproofing agent, 2 parts of strengthening agent, 3 parts of water reducing agent, 1 part of antioxidant and 30 parts of water.

[0023] The silicone microcapsule waterproofing agent is prepared by the following method: 50g of liquid silicone is mixed with 21g of inorganic mineral filler and 103g of water-soluble polymer film-forming wall material, and after stirring, a homogeneous emulsified embedding material solution is formed. It is dried and pulverized to obtain a silicone microcapsule waterproofing agent.

[0024] The liquid organosilicon is a mixture of methylene siloxane and octyltriethoxysilane in a mass ratio of 1:1; the inorganic mineral filler is a mixture of calcium oxide and aluminum sil...

Embodiment 2

[0027] Composition of raw materials (parts by weight): 70 parts of expanded polystyrene, 40 parts of glass fiber reinforced cement, 20 parts of perlite, 20 parts of slag, 20 parts of yellow sand, 25 parts of clay, 15 parts of diatom mud, organic silicon microcapsules 10 parts of waterproofing agent, 7 parts of strengthening agent, 8 parts of water reducing agent, 5 parts of antioxidant and 50 parts of water.

[0028] The silicone microcapsule waterproofing agent is prepared by the following method: 50g of liquid silicone is mixed with 21g of inorganic mineral filler and 103g of water-soluble polymer film-forming wall material, and after stirring, a homogeneous emulsified embedding material solution is formed. It is dried and pulverized to obtain a silicone microcapsule waterproofing agent.

[0029] The liquid organosilicon is a mixture of methylene siloxane and octyltriethoxysilane in a mass ratio of 1:1; the inorganic mineral filler is a mixture of calcium oxide and aluminum ...

Embodiment 3

[0032]Composition of raw materials (parts by weight): 55 parts of expanded polystyrene, 27 parts of glass fiber reinforced cement, 16 parts of perlite, 16 parts of slag, 12 parts of yellow sand, 15 parts of clay, 7 parts of diatom mud, organic silicon microcapsules 6 parts of waterproofing agent, 3 parts of strengthening agent, 4 parts of water reducing agent, 2 parts of antioxidant and 35 parts of water.

[0033] The silicone microcapsule waterproofing agent is prepared by the following method: 50g of liquid silicone is mixed with 21g of inorganic mineral filler and 103g of water-soluble polymer film-forming wall material, and after stirring, a homogeneous emulsified embedding material solution is formed. It is dried and pulverized to obtain a silicone microcapsule waterproofing agent.

[0034] The liquid organosilicon is a mixture of methylene siloxane and octyltriethoxysilane in a mass ratio of 1:1; the inorganic mineral filler is a mixture of calcium oxide and aluminum sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com