A kind of waterproof grade pvb film and preparation method thereof

A film and antioxidant technology, applied in the direction of adhesives, films/sheets without carriers, non-polymer adhesive additives, etc. The membrane is easy to break and other problems, to achieve significant economic and social benefits, good processability and safety performance, and the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

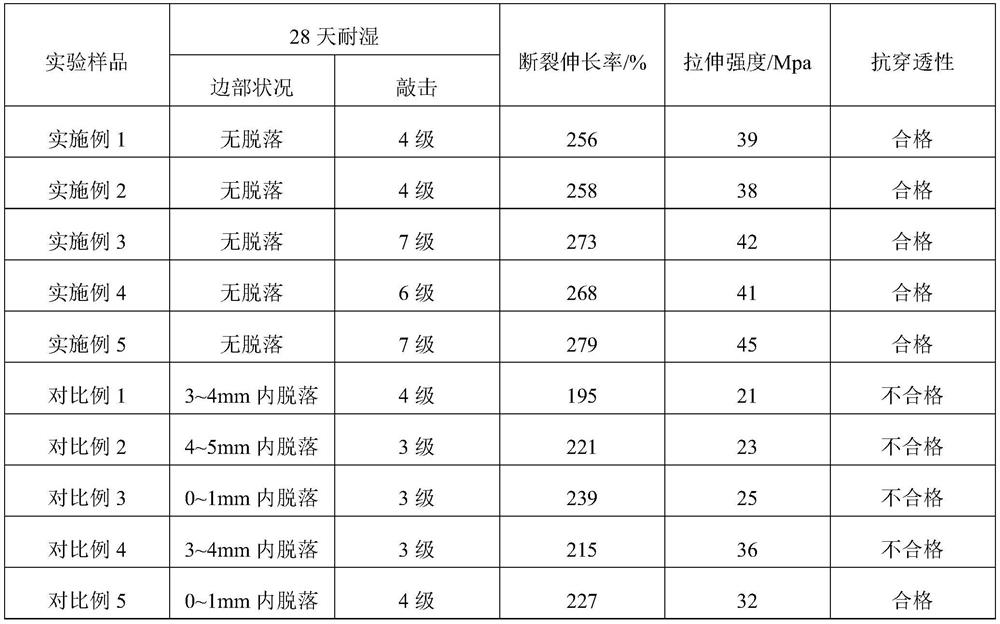

Embodiment 1

[0037] A waterproof grade PVB film, in parts by weight, comprising the following raw materials:

[0038] 65 parts of PVB resin powder, 28 parts of 3GO plasticizer, 0.01 part of antioxidant, 0.01 part of ultraviolet absorber UV-326, 0.01 part of silane coupling agent, 0.001 part of adhesion modifier, 8 parts of SGP;

[0039] Wherein, the hydroxyl content of the resin powder used is 20%, the viscosity of the resin powder is 200cp (20°C), and the melt index is 1.2g / 10min;

[0040] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168; the mass ratio of antioxidant 1010 and antioxidant 168 is 1:1;

[0041] The cohesion regulator is a mixture of magnesium acetate and potassium formate, and the mass ratio of the two is 4:3;

[0042] Described silane coupling agent is the mixture of γ-glycidyl ether oxypropyltriethoxysilane, β-(3,4, epoxycyclohexyl)-ethyltrimethoxysilane, and the consumption ratio of the two is 1:3;

[0043] The preparation method of described water...

Embodiment 2

[0047] A waterproof grade PVB film, in parts by weight, comprising the following raw materials:

[0048] 72 parts of PVB resin powder, 35 parts of 3GO plasticizer, 0.03 part of antioxidant, 0.02 part of ultraviolet absorber UV-326, 0.001 part of silane coupling agent, 0.01 part of adhesion regulator, 0.8 part of SGP;

[0049] Wherein, the hydroxyl content of the resin powder used is 17%, the viscosity of the resin powder is 300cp (20°C), and the melt index is 0.8g / 10min.

[0050] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168; the mass ratio of antioxidant 1010 to antioxidant 168 is 1:4.

[0051] The cohesion modifier is a mixture of magnesium acetate and potassium formate, and the mass ratio of the two is 1:1;

[0052] Described silane coupling agent is the mixture of γ-glycidyl ether oxypropyltriethoxysilane, β-(3,4, epoxycyclohexyl)-ethyltrimethoxysilane, and the consumption ratio of the two is 1:1;

[0053] The preparation method of described water...

Embodiment 3

[0057] A waterproof grade PVB film, in parts by weight, the waterproof grade PVB film comprises the following raw materials: 65 parts of PVB resin powder, 28 parts of 3GO plasticizer, 0.01 part of antioxidant, 0.01 part of ultraviolet absorber UV-326 0.01 part of silane coupling agent, 0.001 part of cohesion regulator, 8 parts of SGP, 2 parts of cresyl butyl phthalate, and 8 parts of triphenyl phosphate.

[0058] Wherein, the hydroxyl content of the resin powder used is 20%, the viscosity of the resin powder is 200cp (20°C), and the melt index is 1.2g / 10min;

[0059] The antioxidant is a mixture of antioxidant 1010 and antioxidant 168; the mass ratio of antioxidant 1010 and antioxidant 168 is 1:1;

[0060] The cohesion regulator is a mixture of magnesium acetate and potassium formate, and the mass ratio of the two is 4:3;

[0061] Described silane coupling agent is the mixture of γ-glycidyl ether oxypropyltriethoxysilane, β-(3,4, epoxycyclohexyl)-ethyltrimethoxysilane, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com