Application of thermal tackifying emulsion polymer, and fracturing fluid sand carrying agent and slickwater drag reducer based on thermal tackifying emulsion polymer

A kind of emulsion polymer and polymer technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of poor sand carrying performance or drag reduction efficiency, cumbersome liquid preparation process, etc., and achieve the goal of shortening the dissolution time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

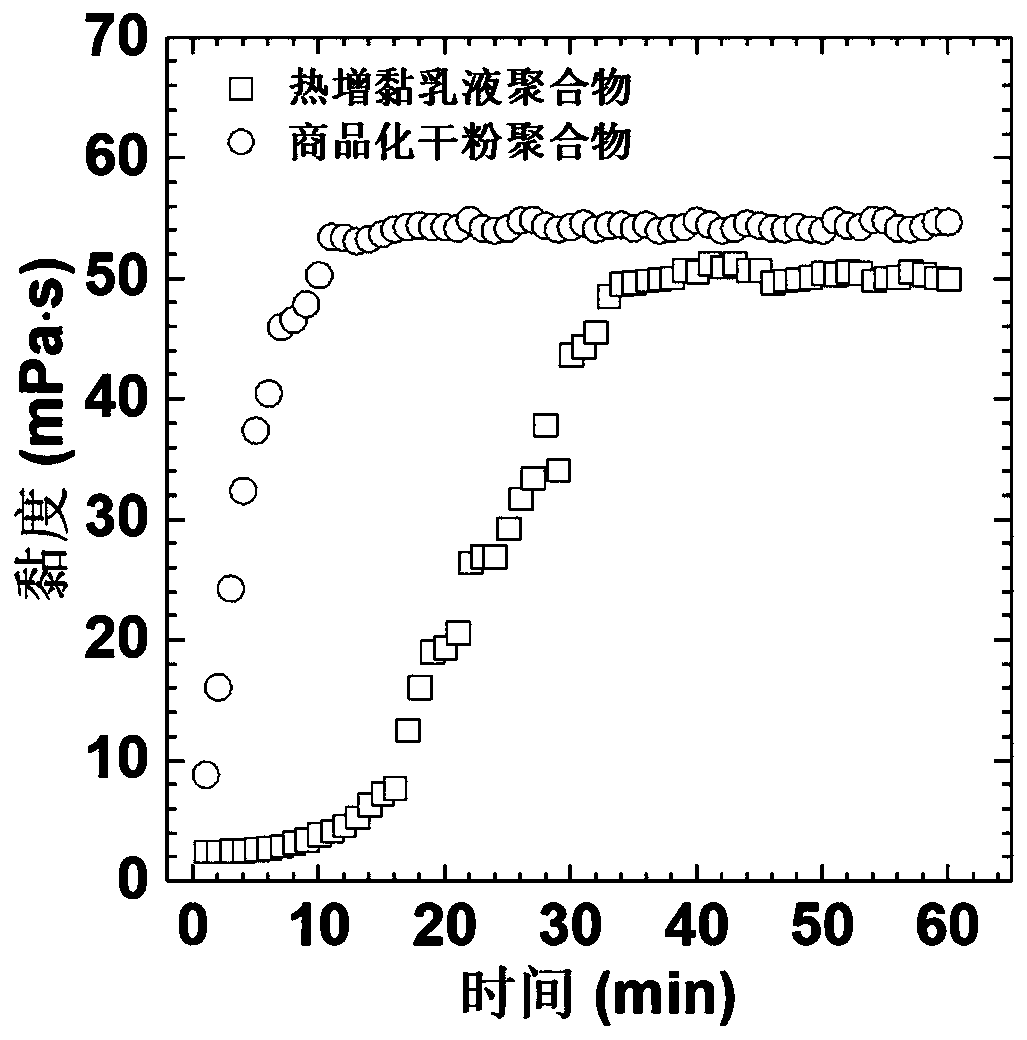

[0046] A heat-increased slick water drag reducer provided in this embodiment comprises, by mass percentage: 0.1% heat-increased polymer, 0.01% phase inverting agent and the balance of water.

[0047] The heat-adhesive polymer is added in the form of a heat-adhesive emulsion polymer (the following examples are the same), and the heat-adhesive emulsion polymer is made of Pluronic (BASF company's product model) block polyether temperature-sensitive macromolecule, anion Monomer and acrylamide monomer obtained by polymerization. The Pluronic thermosensitive macromolecule is block polyether F108. The anionic monomer is a mixture of sodium acrylate and 2-acrylamide-2-methylpropanesulfonic acid neutralized salt. The anti-phase agent is a mixture of ethoxylated long-chain fatty alcohol and nonylphenol polyoxyethylene ether.

[0048] The heat-tackifying emulsion polymer is prepared by the following method: 31.7% (w / w, the same below) of acrylamide, 9.5% of sodium acrylate and 2-acryla...

Embodiment 2

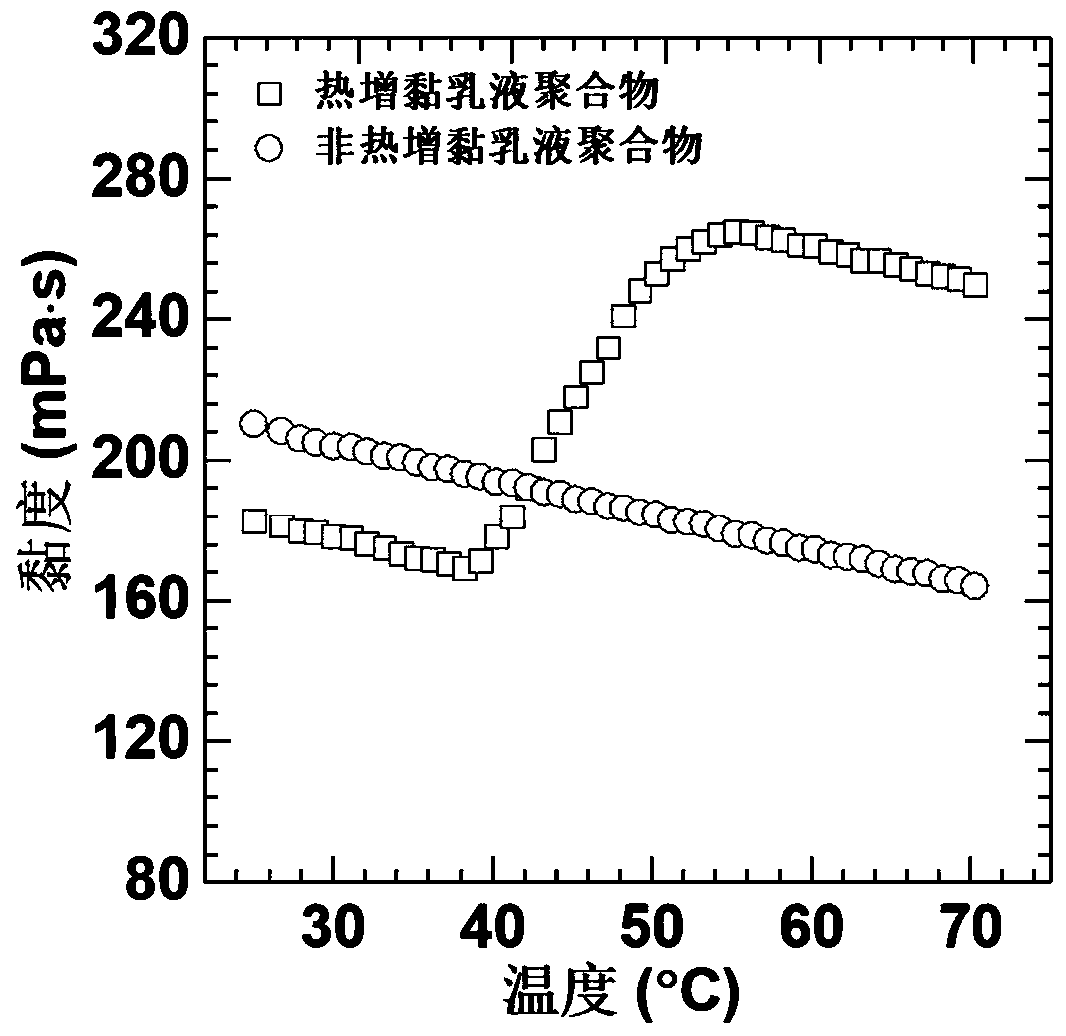

[0053] The thermal viscosity-increasing suspension sand-carrying agent provided in this embodiment comprises, by mass percentage, raw materials: 0.2% thermal viscosity-increasing polymer, 0.02% phase inverting agent and the balance of water.

[0054] The heat-tackifying emulsion polymer is prepared by the following method: the sand-carrying agent of the heat-tackifying emulsion polymer is a polymer of Pluronic block polyether temperature-sensitive macromolecule, anionic monomer and acrylamide monomer. The Pluronic macromolecule is block polyether F127. The anionic monomer is acrylic acid. The anti-phase agent is a mixture of ethoxylated long-chain fatty alcohol and alcohol polyoxyethylene ether.

[0055] Dissolve 31.7% (w / w, the same below) of acrylamide, 9.5% of acrylic acid, 8.6% of F127, and 5.0% of sodium chloride in deionized water (accounting for 45.2% of the total mass of the water phase), and adjust the pH =7.0, formulated as an aqueous phase. Dissolve 14.0% emulsif...

Embodiment 3

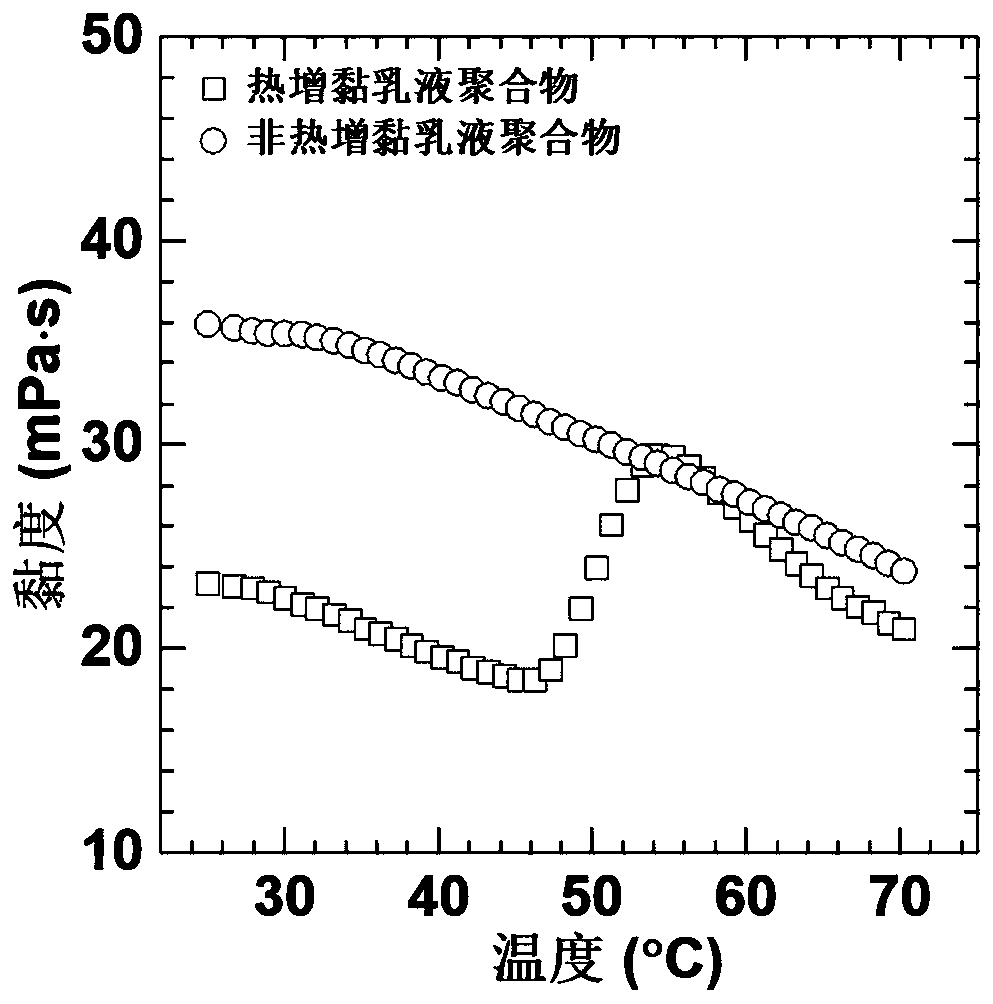

[0061] The heat-increased slick water drag reducer provided in this embodiment comprises, by mass percentage, raw materials: 0.03% heat-increased polymer, 0.003% phase inverting agent and the balance of water.

[0062] The thermal viscosity-increasing emulsion polymer is a polymer of Pluronic block polyether temperature-sensitive macromolecule, anion monomer and acrylamide monomer. The Pluronic macromolecule is block polyether F127. The anionic monomer is sodium acrylate. The reverse phase agent is ethoxylated long-chain fatty alcohol.

[0063]The heat-tackifying emulsion polymer was prepared by the following method: 23.7% (w / w, the same below) of acrylamide, 9.5% of acrylic acid, 16.6% of F127, 5.0% of sodium chloride were dissolved in deionized In water (accounting for 45.2% of the total mass of the water phase), adjust the pH=7.0 to form the water phase. Dissolve 14.0% emulsifier HB246 in mineral oil (accounting for 86.0% of the total mass of the oil phase), heat to 50°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com