Preparation method of synchronously-stretched polypropylene high-temperature-resistant film for wireless charging

A technology of synchronous stretching and wireless charging, which is applied in the field of polypropylene film, can solve the problems that polypropylene film cannot be mass-produced, ultra-thin films cannot be solved, and longitudinal thermal shrinkage is large, so as to improve film-forming property and thickness uniformity , the effect of large adjustment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

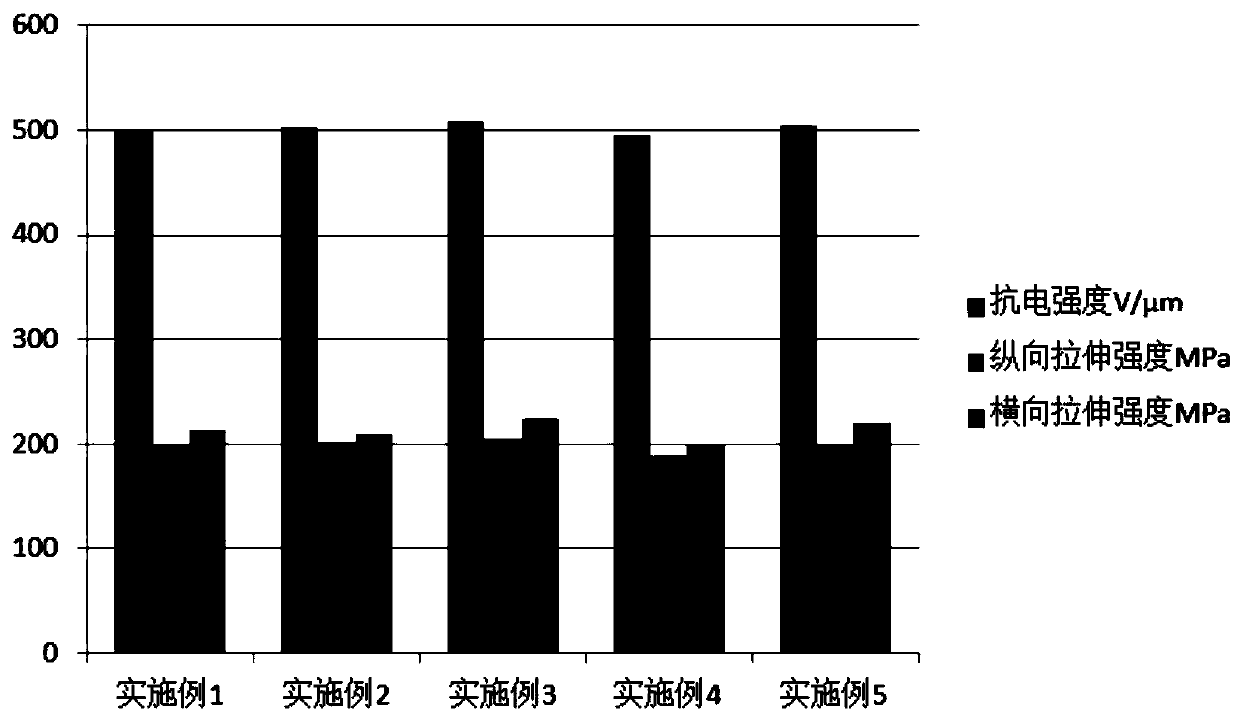

Examples

Embodiment 1

[0031] A method for preparing a synchronously stretched polypropylene high temperature resistant film for wireless charging

[0032] Include the following steps:

[0033] Step I, raw material preparation: dry the raw material for 3 hours at a temperature of 100° C., and set aside; wherein, the raw material is polypropylene with an isotacticity of 98.1% and an ash content of 15 ppm, p-dimethyldibenzylidene sorbitol and Modified silica; the mass ratio of polypropylene, p-dimethyldibenzylidene sorbitol and modified silica is 10:0.01:0.65; the preparation process of modified silica is as follows: the mass fraction is 1.5% Add silicon dioxide to the modified agent solution and stir and mix for 3 minutes, then grind and disperse for 2 hours, and finally filter and dry to obtain the modified silicon dioxide; wherein, in the modified agent solution, sodium lauryl sulfate, dopamine, The mass ratio of propylene glycol and water is 1:0.6:3:15; the mass ratio of modifier solution to sili...

Embodiment 2

[0039] A method for preparing a synchronously stretched polypropylene high temperature resistant film for wireless charging

[0040] Include the following steps:

[0041]Step I, raw material preparation: dry the raw material for 4 hours at a temperature of 120° C., and set aside; wherein, the raw material is polypropylene with an isotacticity of 98.9% and an ash content of 20 ppm, p-dimethyldibenzylidene sorbitol and Modified silica; the mass ratio of polypropylene, p-dimethyldibenzylidene sorbitol and modified silica is 10:0.02:0.65; the preparation process of modified silica is as follows: the mass fraction is 3.5% Add silicon dioxide to the modified agent solution and stir and mix for 5 minutes, then grind and disperse for 6 hours, and finally filter and dry to obtain the modified silicon dioxide; wherein, in the modified agent solution, sodium lauryl sulfate, dopamine, The mass ratio of propylene glycol and water is 2:0.6:3:15; the mass ratio of modifier solution to silic...

Embodiment 3

[0047] A method for preparing a synchronously stretched polypropylene high temperature resistant film for wireless charging

[0048] Include the following steps:

[0049] Step 1, raw material preparation: the raw material is dried under the condition of 105 ℃ for 4 hours and set aside; wherein, the raw material is polypropylene with isotacticity of 98.3% and ash content of 16ppm, p-dimethyldibenzylidene sorbitol and Modified silica; the mass ratio of polypropylene, p-dimethyldibenzylidene sorbitol and modified silica is 10:0.02:0.65; the preparation process of modified silica is as follows: the mass fraction is 2.0% Add silicon dioxide to the modifying agent solution and stir and mix for 5 minutes, then grind and disperse for 3 hours, and finally filter and dry to obtain the modified silicon dioxide; wherein, in the modifying agent solution, sodium lauryl sulfate, dopamine, The mass ratio of propylene glycol and water is 1.2:0.6:3:15; the mass ratio of modifier solution to si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com