A ti-doped α-fe 2 o 3 Nanorod composite mofs heterojunction photoanode and its preparation method and application

A -fe2o3, heterojunction technology, applied in photosensitive equipment, photovoltaic power generation, capacitors, etc., can solve the problems of limiting photoanode water splitting performance, difficult operation, complicated process, etc., and achieve good photoelectric catalytic water splitting ability and good conduction The effect of carriers and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

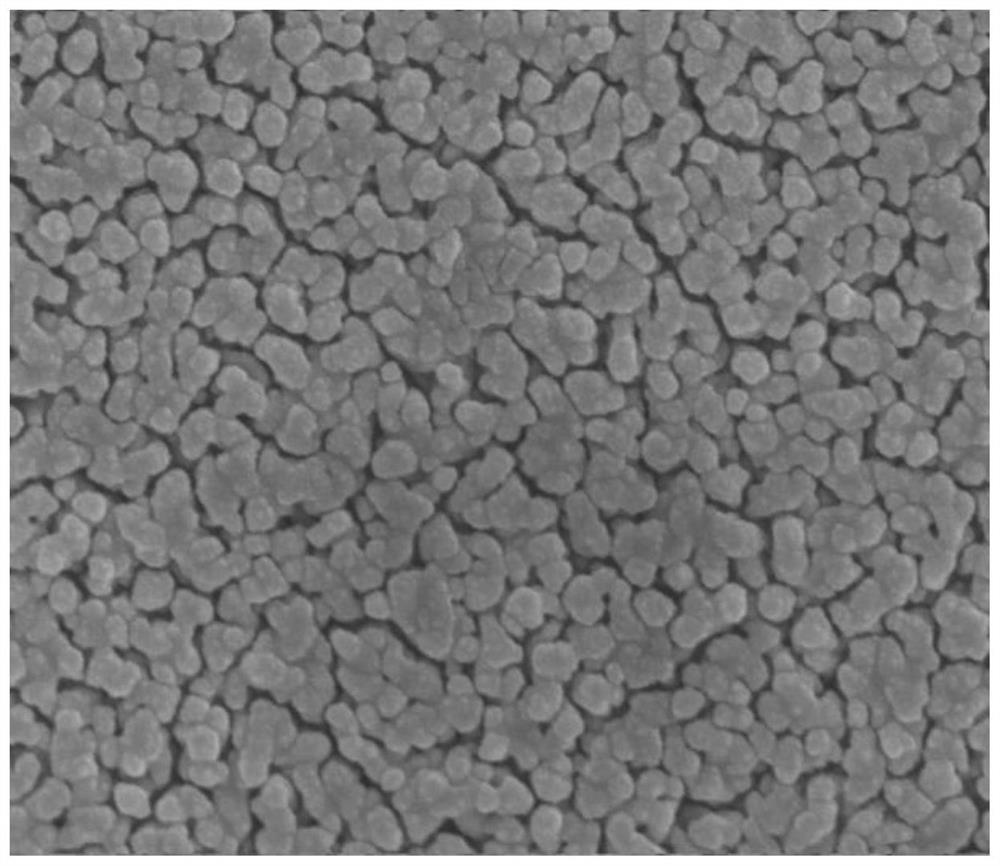

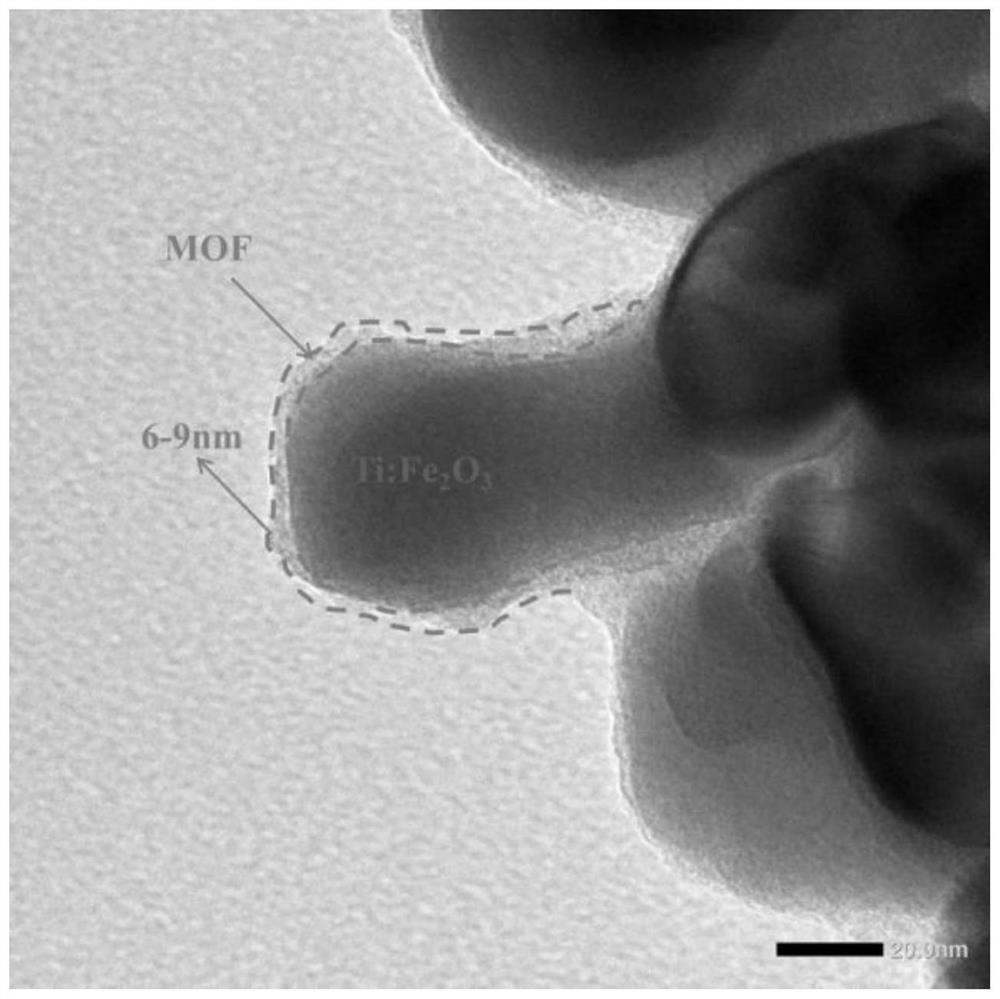

[0033] In this example, Ti doped with α-Fe 2 o 3 A method for preparing a nanorod composite MOFs heterojunction photoanode, comprising the following steps:

[0034] 1) To Ti 3 AlC 2 Hydrofluoric acid was slowly added dropwise into the solution, Ti 3 AlC 2 The solid-to-liquid mass ratio with hydrofluoric acid is 1:5, and the stirring is continued for 24 hours to obtain Ti 3 C 2 solution;

[0035] 2) Ti will be obtained 3 C 2 The solution was cleaned by centrifugation with deionized water, and dried in a vacuum oven to obtain Ti 3 C 2 powder;

[0036] 3) 0.5 parts by mass of ferric chloride hexahydrate, 0.01 parts by mass of Ti 3 C 2 and 0.1 mass parts of urea were dissolved in 50 mass parts of deionized water, and stirred for 5 min to obtain Ti-doped α-Fe 2 o 3 precursor solution;

[0037] 4) Conductive glass is placed in the reactor, the conductive surface of the conductive glass faces the inner wall of the reactor; then the Ti doped α-Fe 2 o 3 The precursor ...

Embodiment 2

[0041] In this example, Ti doped with α-Fe 2 o 3 A method for preparing a nanorod composite MOFs heterojunction photoanode, comprising the following steps:

[0042] 1) To Ti 3 AlC 2 Hydrofluoric acid was slowly added dropwise into the solution, Ti 3 AlC 2 The solid-to-liquid mass ratio with hydrofluoric acid is 1:10, and the stirring is continued for 36 hours to obtain Ti 3 C 2 solution;

[0043] 2) Ti will be obtained 3 C 2 The solution was cleaned by centrifugation with deionized water, and dried in a vacuum oven to obtain Ti 3 C 2 powder;

[0044] 3) 1 mass part of ferric chloride hexahydrate, 0.02 mass part of Ti 3 C 2 and 0.5 parts by mass of urea were dissolved in 50 parts by mass of deionized water and stirred for 20 min to obtain Ti-doped α-Fe 2 o 3 precursor solution;

[0045] 4) Conductive glass is placed in the reactor, the conductive surface of the conductive glass faces the inner wall of the reactor; then the Ti doped α-Fe 2 o 3 The precursor sol...

Embodiment 3

[0050] In this example, Ti doped with α-Fe 2 o 3 A method for preparing a nanorod composite MOFs heterojunction photoanode, comprising the following steps:

[0051] 1) To Ti 3 AlC 2 Hydrofluoric acid was slowly added dropwise into the solution, Ti 3 AlC 2 The solid-to-liquid mass ratio with hydrofluoric acid is 1:20, and the stirring is continued for 48 hours to obtain Ti 3 C 2 solution;

[0052] 2) Ti will be obtained 3 C 2 The solution was cleaned by centrifugation with deionized water, and dried in a vacuum oven to obtain Ti 3 C 2 powder;

[0053] 3) 0.75 parts by mass of ferric chloride hexahydrate, 0.03 parts by mass of Ti 3 C 2 and 0.3 parts by mass of urea were dissolved in 50 parts by mass of deionized water, and stirred for 30 min to obtain Ti-doped α-Fe 2 o 3 precursor solution;

[0054] 4) Conductive glass is placed in the reactor, the conductive surface of the conductive glass faces the inner wall of the reactor; then the Ti doped α-Fe 2 o 3 The p...

PUM

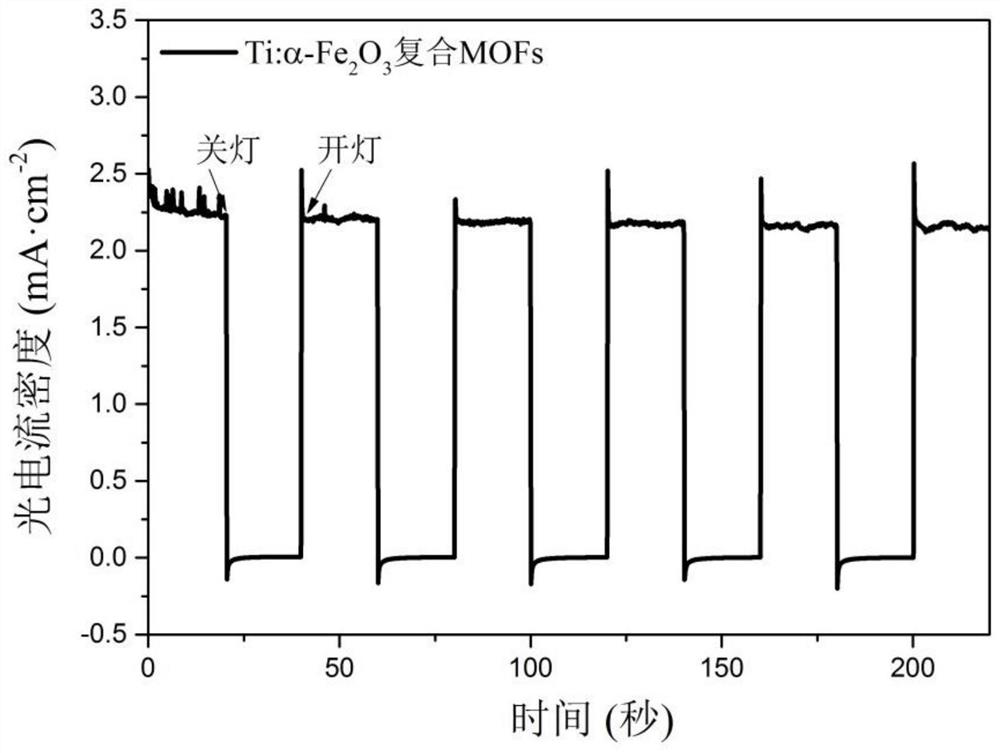

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com