Packaged perovskite solar cell and packaging method

A technology of solar cells and packaging methods, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of perovskite decomposition, perovskite layer decomposition, perovskite material destruction, etc., to improve stability and reduce attenuation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

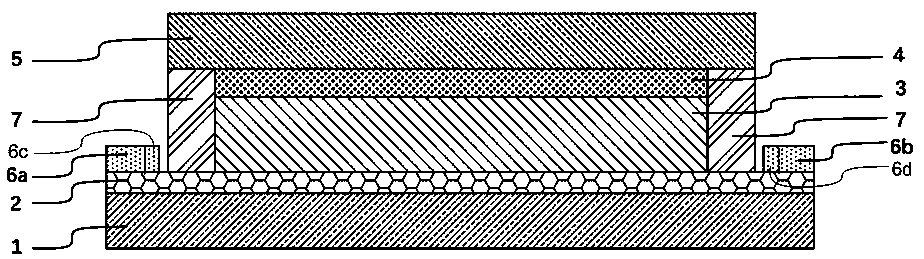

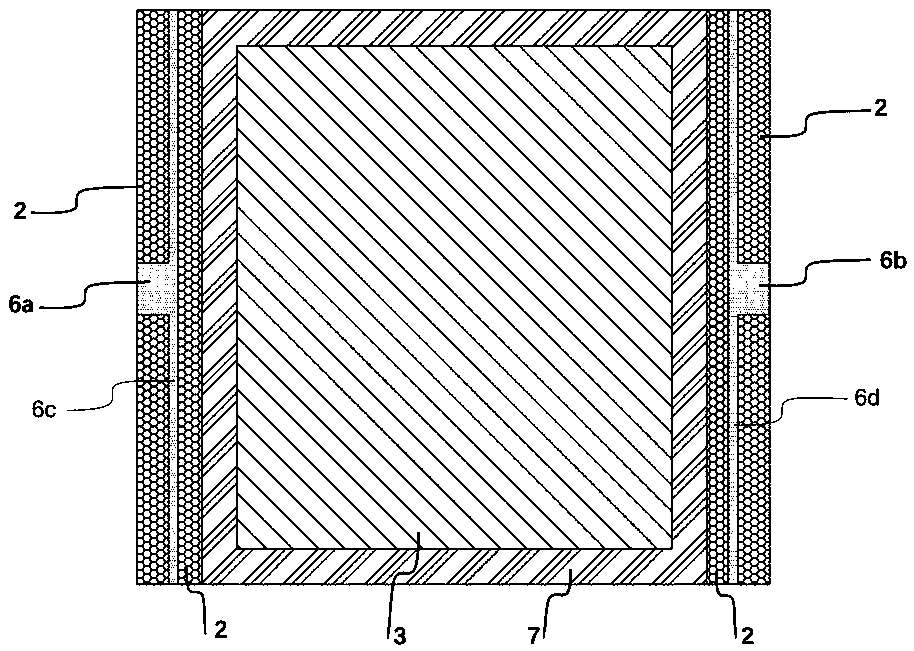

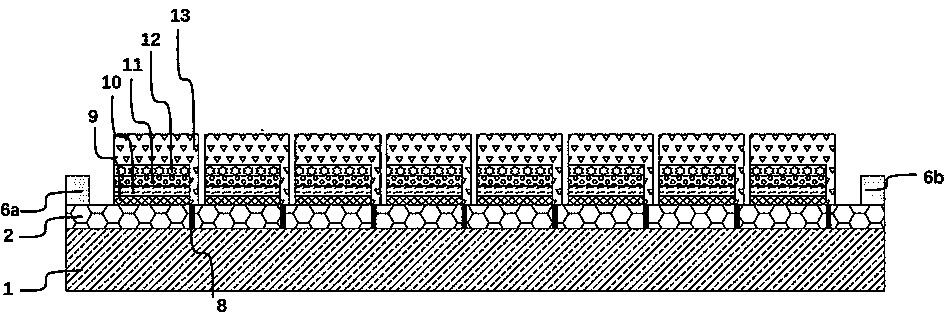

[0071] MAPbI 3 The packaging of perovskite solar cell modules is an example. Among them, the perovskite solar cell module 3 includes 8 perovskite solar cell units, each unit includes an FTO layer (transparent conductive layer 2), a hole blocking layer 9, an electron transport layer 10, a MAPbI 3 Perovskite layer (perovskite light-absorbing layer 11), hole transport layer 12, carbon counter electrode layer (counter electrode layer 13), wherein, MAPbI 3 The perovskite layer is arranged between the electron transport layer and the carbon counter electrode layer; the FTO layers of adjacent battery cells are separated by etching lines 8, and the counter electrode layers are connected to the FTO layers of adjacent unit cells across the etching lines to realize 8 battery cells connected in series.

[0072] Such as figure 1 , figure 2 with image 3 As shown, this embodiment relates to a packaged perovskite solar cell module, the front of the cell module is a transparent substrat...

Embodiment 2

[0090] This embodiment provides a perovskite solar cell unit structure different from that of Embodiment 1, such as Figure 4 As shown, it includes a hole blocking layer 9, an electron transport layer 10 located on the upper surface of the hole blocking layer 9, an insulating layer 14 located on the upper surface of the electron transport layer 10, and a perovskite light absorbing layer located on the upper surface of the insulating layer 14. Layer 11, a counter electrode layer 13 located on the upper surface of the perovskite light-absorbing layer 11, wherein the counter electrode layer 13 also covers one side of the perovskite solar cell unit. Since the perovskite light-absorbing layer 11 can transport both holes and electrons, in order to prevent the holes in the perovskite light-absorbing layer 11 from being transferred to the electron-transporting layer 10, an insulating layer 14 needs to be added to block hole transport. Wherein, the perovskite precursor solution penetra...

Embodiment 3

[0104] This example utilizes CsPbI 2 Br perovskite layer (perovskite light-absorbing layer) replaces MAPbI in Example 1 3 The perovskite layer, and the set temperature of the laminator was changed to 150° C., and the rest of the structure and packaging steps were the same as in Embodiment 1, and will not be repeated here.

[0105] Table 5 shows the perovskite solar cells before and after lamination packaging in this embodiment at AM1.5, 100mW / cm 2 The photoelectric conversion parameters measured under the light source.

[0106] The perovskite solar cell performance parameters (AM1.5, 100mW / cm 2 )

[0107]

[0108] Among them, Voc is the open circuit voltage, Jsc is the short circuit current, FF is the fill factor, and Eff is the photoelectric conversion efficiency.

[0109] The packaging method of the present invention is used to package the above-mentioned battery. After packaging, the efficiency of the battery does not decrease, but is slightly improved. It proves tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com