Zinc-nickel flow battery negative electrode and its application and zinc-nickel flow battery

A flow battery, zinc-nickel technology, applied in battery electrodes, fuel cells, regenerative fuel cells, etc., can solve the problems of system stability hazards, multi-zinc element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Negative electrode preparation: the substrate is 36cm 2 Carbon felt, impregnated in 1.0mol / L zinc acetate solution, impregnated for 30min at a temperature of 30°C; dried at 60°C, transferred to a tube furnace, and burned at 400°C for 3h in an oxygen atmosphere to obtain the desired negative electrode.

[0020] The positive pole is loaded with 5mg / cm 2 Carbon Felt of Nickel Hydroxide.

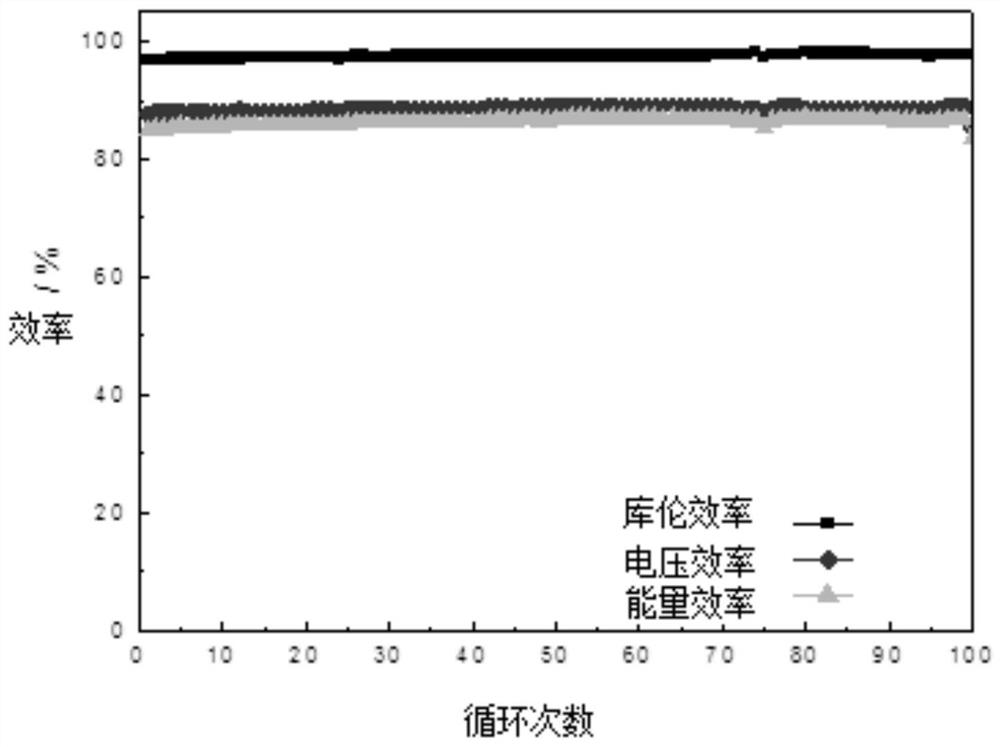

[0021] Use it to assemble the battery, the negative electrode electrolyte is 6L of alkaline solution of 4mol / L potassium hydroxide containing 0.5 mol / L zinc ion; the positive electrode electrolyte is the alkaline solution of potassium hydroxide containing 0.5 mol / L zinc ion 6L; using 10mA / cm 2 The current density for charging, 40mA / cm 2 The current density of the discharge cycle is carried out. The charging cut-off condition of the battery is that the voltage is not higher than 2.0V, and the discharge cut-off condition is that the voltage is not lower than 2V. from figure 1 It can b...

Embodiment 2

[0023] The base is 36cm 2 Carbon felt, impregnated in 2.0mol / L zinc sulfate solution, soaked for 60min at a temperature of 50°C; dried at 80°C, transferred to a tube furnace, and burned at 300°C for 5h in an oxygen atmosphere. Get the required samples.

Embodiment 3

[0025] The base is 36cm 2 Carbon felt, impregnated in 1.5mol / L zinc nitrate solution, soaked for 40min at a temperature of 40°C; after drying at 70°C, transferred to a tube furnace, and burned at 350°C for 4h in an oxygen atmosphere. Get the required samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com