Method for removing trace diquat in water

A diquat and trace technology, which is applied in separation methods, chemical instruments and methods, water pollutants, etc., can solve the problems of small volume of water samples, high cost of solid-phase extraction cartridges, and difficulty in popularization, etc., so as to save consumption, Remarkable processing effect, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

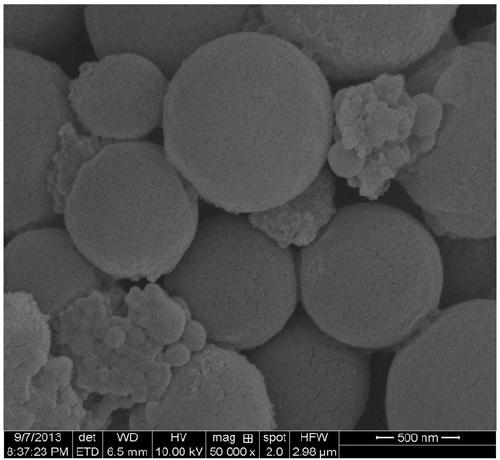

[0034] In a 200mL beaker, add 1.0g of Fe(NO 3 ) 3 ·9H 2 O, 1.0g of Mn(NO 3 ) 2 ·4H 2 O and 1.0g of ZrCl 4 After mixing, add 5.0mL of 0.1mol / L hydrochloric acid and 80mL of DMF and stir to dissolve. After the dissolution is complete, add 2.0g of 2-aminoterephthalic acid, stir and mix, and transfer to a 250mL pressure-resistant closed reactor after dissolution. After cooling, the reaction solution was transferred to a 100mL centrifuge tube and centrifuged at 3000rpm to obtain a crude product. The product was washed twice with 20mL DMF and 20mL ethanol, and then the product powder was placed Put it in a 50mL colorimetric tube with a stopper, soak in absolute ethanol for 72 hours, and finally vacuum dry at room temperature to obtain Fe / Zr / Mn-MOFs. The SEM image is shown in figure 1 , The particle size is about 100-300μm.

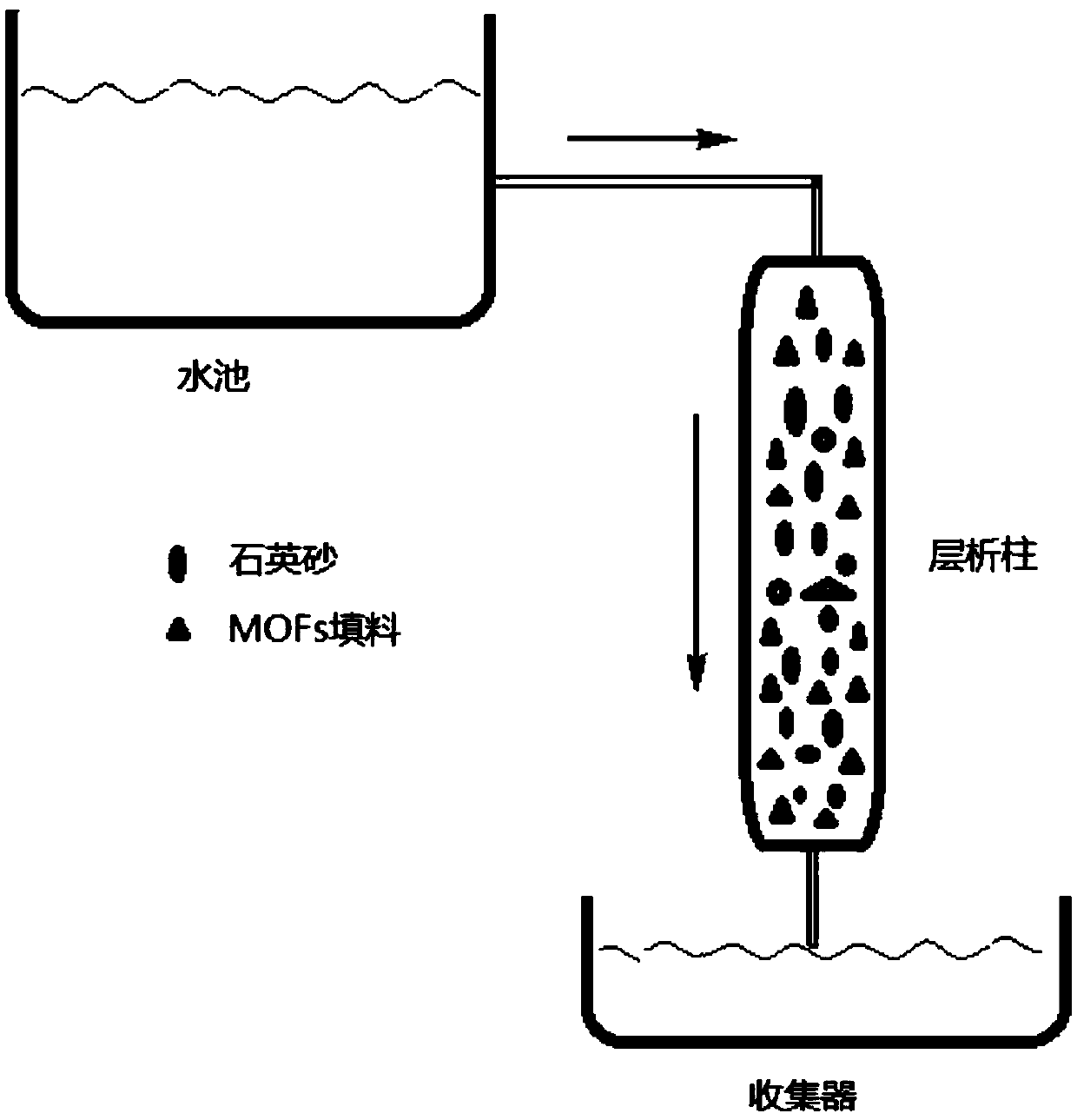

[0035] The prepared Fe / Zr / Mn-MOFs material is mixed with quartz sand with a particle size of 0.05mm~0.1mm in a weight ratio of 2:1 and then uniformly filled in the ...

Embodiment 2

[0037] In a 200mL beaker, add 1.0g of Fe(NO 3 ) 3 ·9H 2 O, 2.0g of Mn(NO 3 ) 2 ·4H 2 O and 1.5g of ZrCl 4 After mixing, add 5.0mL of 0.1mol / L hydrochloric acid and 80mL of DMF and stir to dissolve. After the dissolution is complete, add 2.5g of 2-aminoterephthalic acid, stir and mix, and then transfer to 250mL pressure-resistant airtight reaction after dissolution In the kettle, react at 90°C for 15 hours. After cooling, transfer the reaction solution to a 100 mL centrifuge tube and centrifuge at 3000 rpm to obtain a crude product. Wash the product twice with 20 mL DMF and 20 mL ethanol. The 50mL colorimetric tube of the stopper was soaked in absolute ethanol for 72 hours, and finally dried under vacuum at room temperature to obtain Fe / Zr / Mn-MOFs material with a particle size of about 100-300 μm.

[0038] The Fe / Zr / Mn-MOFs material obtained is mixed with quartz sand with a particle size of 0.1mm~0.5mm at a weight ratio of 3:1 and then uniformly filled in the chromatography filter ...

Embodiment 3

[0040] In a 200mL beaker, add 1.0g of Fe(NO 3 ) 3 ·9H 2 O, 2.5g of Mn(NO 3 ) 2 ·4H 2 O and 0.5g of ZrCl 4 After mixing, add 5.0mL of 0.1mol / L hydrochloric acid and 80mL of DMF and stir to dissolve. After the dissolution is complete, add 1.5g of 2-aminoterephthalic acid, stir and mix, and then transfer to 250mL pressure-resistant airtight reaction In the kettle, react at 100°C for 18 hours. After cooling, transfer the reaction solution to a 100mL centrifuge tube, centrifuge at 3000rpm to obtain a crude product, and rinse it with 20mL DMF and 20mL ethanol twice. The product powder is placed in A 50mL colorimetric tube with a stopper was soaked in absolute ethanol for 72 hours, and finally dried in a vacuum at room temperature to obtain Fe / Zr / Mn-MOFs with a particle size of about 100-300 μm.

[0041] Mix the obtained Fe / Zr / Mn-MOFs material with quartz sand with a particle size of 0.1mm~0.5mm at a weight ratio of 4:1 and evenly fill it in the chromatography filter column. At the same ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com