Bifunctional water electrolysis catalyst and preparation method and application thereof

A water electrolysis and dual-function technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrolytic components, etc., can solve the problems of limited reports and achieve the effect of rich morphology, simple and convenient operation, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

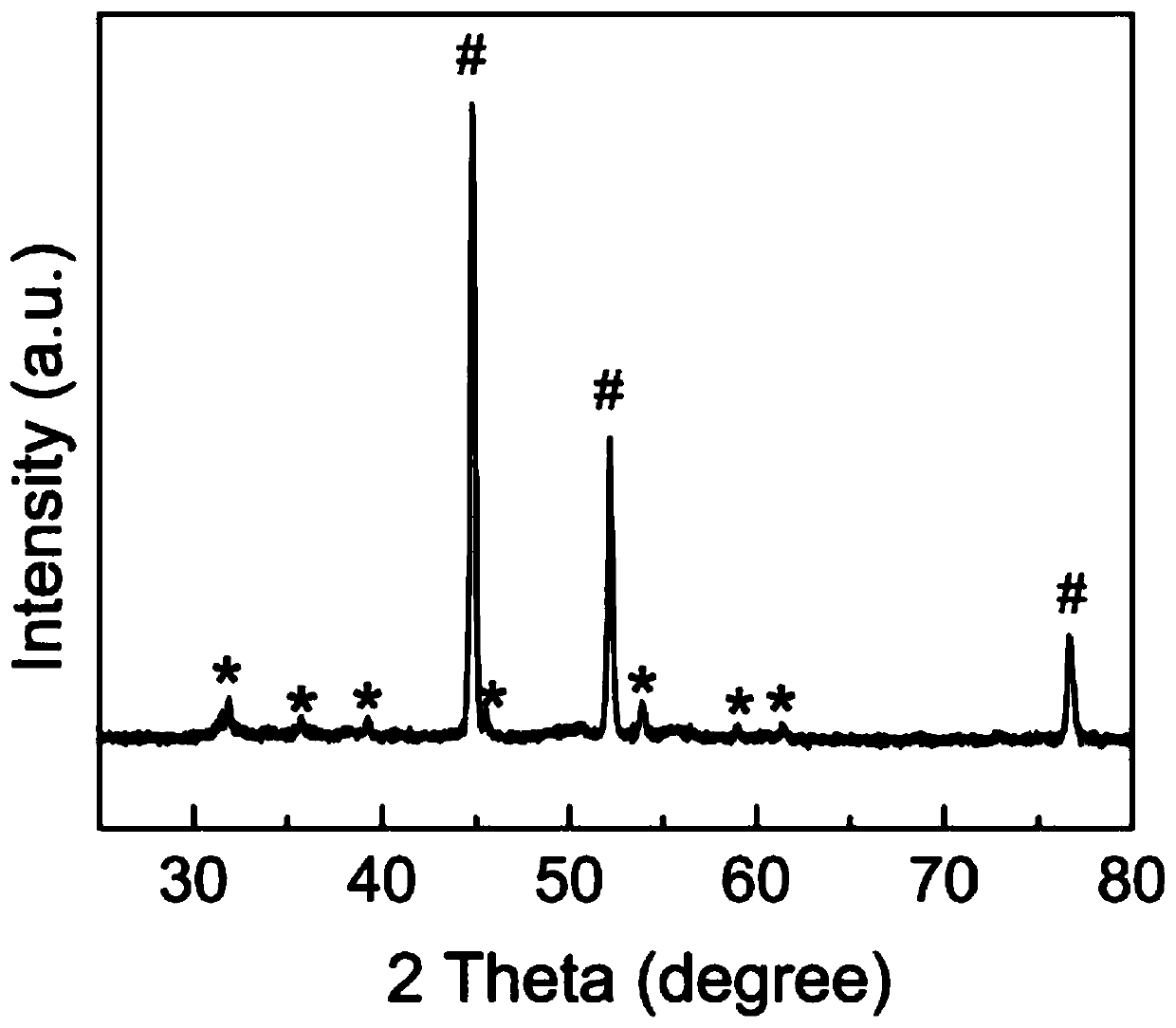

[0027] NeS 2 The growth of the nanotube material was accomplished as follows: 0.2 mmol nickel chloride (NiCl 2 ·6H 2 O), 0.5 mmol sodium thiosulfate (Na 2 S 2 o 3 ·6H 2 O) and 0.11g of polyvinylpyrrolidone were dissolved in 60mL of deionized water to obtain an aqueous reaction solution; the aqueous reaction solution was transferred to a 100mL polytetrafluoroethylene autoclave, and the treated foamed nickel (size 1 × 3cm) was put into the reaction in the cauldron. Keep the reactor at 150°C for 10h, after cooling to room temperature, wash the nickel foam thoroughly with deionized water and ethanol, and then dry it at 70°C for 10h to obtain a bifunctional electrolytic water catalyst.

Embodiment 2

[0029] NeS 2 The growth of the nanotube material was accomplished as follows: 0.2 mmol nickel chloride (NiCl 2 ·6H 2 O), 0.5 mmol sodium thiosulfate (Na 2 S 2 o 3 ·6H 2 O) and 0.11g of polyvinylpyrrolidone were dissolved in 70mL of deionized water to obtain a reaction aqueous solution; the reaction solution was transferred to a 100mL polytetrafluoroethylene autoclave, and the treated foamed nickel (size 1 × 3cm) was put into the reaction in the cauldron. Keep the reactor at 155°C for 10h, after cooling to room temperature, wash the nickel foam thoroughly with deionized water and ethanol, and then dry it at 70°C for 10h to obtain a bifunctional electrolytic water catalyst.

Embodiment 3

[0031] NeS 2 The growth of the nanotube material was accomplished as follows: 0.2 mmol nickel chloride (NiCl 2 ·6H 2 O), 0.5 mmol sodium thiosulfate (Na 2 S 2 o 3 ·6H 2 O) and 0.11g of polyvinylpyrrolidone were dissolved in 76mL of deionized water to obtain an aqueous reaction solution; the aqueous reaction solution was transferred to a 100mL polytetrafluoroethylene autoclave, and the treated foamed nickel (size 1 × 3cm) was put into the reaction in the cauldron. Keep the reactor at 150°C for 10h, after cooling to room temperature, wash the nickel foam thoroughly with deionized water and ethanol, and then dry it at 70°C for 10h to obtain a bifunctional electrolytic water catalyst.

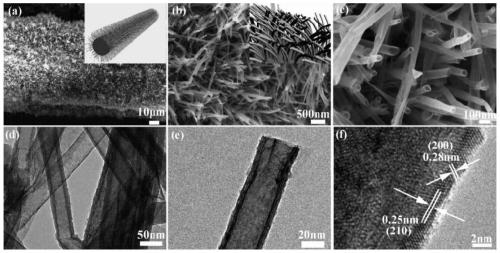

[0032] In the prepared bifunctional electrolytic water catalyst, NiS 2 The nanotubes grow approximately vertically on the nickel foam substrate in the form of arrays, with a diameter of 20-80nm and a length of 100-500nm.

[0033]The process of using the bifunctional electrolytic water catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com