High-molecular-weight and ultrahigh-molecular-weight maleic anhydride-styrene monomer alternating copolymer and preparation method thereof

An alternating copolymer and ultra-high molecular weight technology, which is applied in the field of maleic anhydride-styrene monomer alternating copolymer and its preparation, can solve the problems of upper limit temperature limitation and the like, and achieves easy operation, simple post-processing process, Conducive to the effect of industrial application and commercial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a kind of preparation method of maleic anhydride-styrene monomer alternating copolymer, comprising the following steps:

[0068] Under the action of Lewis acid and the condition of anhydrous and oxygen-free, maleic anhydride monomers and styrene monomers are copolymerized in a reaction medium to obtain alternating copolymers of maleic anhydride-styrene monomers.

[0069]In principle, the present invention has no particular limitation on the specific selection of the Lewis acid. Those skilled in the art can select and adjust according to the actual preparation situation, product performance and quality requirements. The present invention ensures that under the condition of high molecular weight, it has better The structure of strict alternating copolymerization increases the glass transition temperature of the alternating copolymer, which is more conducive to subsequent applications. The Lewis acid preferably includes alkyl aluminum, al...

Embodiment 1

[0093] Under anhydrous and oxygen-free conditions, maleic anhydride (3.6mmol, 0.353g), styrene (3.6mmol, 3.75g) and 1.5mL toluene were added to the reaction vessel, and after stirring at room temperature, triethylaluminum (0.2mL×0.5M) was injected into the reaction solution. Then, the polymerization reactor was placed in a 50° C. oil bath to react for 3.5 hours. Then, isopropanol was added to terminate the reaction, washed several times with isopropanol and diethyl ether, and dried in a vacuum oven at 60° C. to constant weight to obtain a white solid powder with a yield of 72.7%.

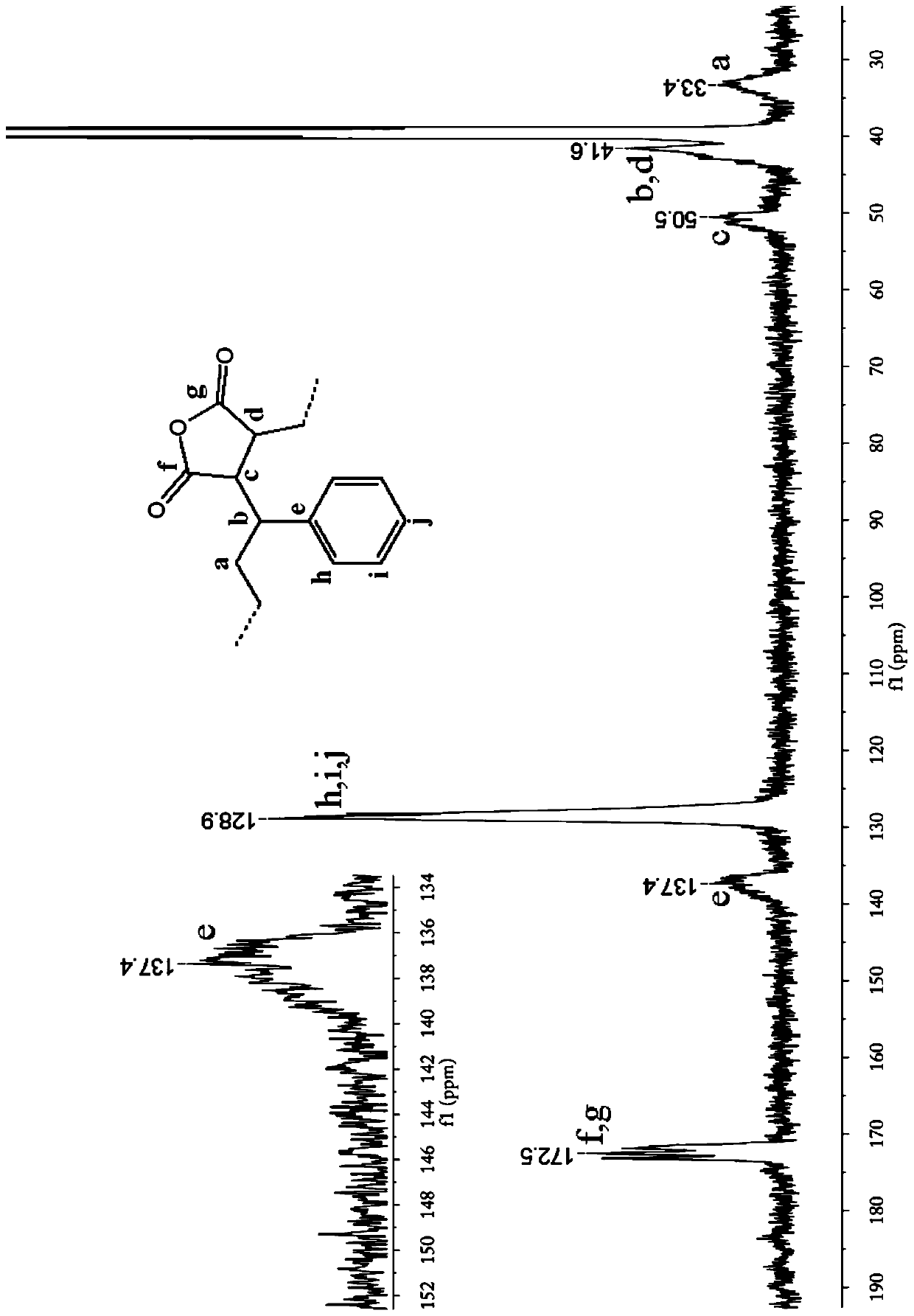

[0094] The maleic anhydride-styrene copolymer prepared in Example 1 of the present invention was characterized.

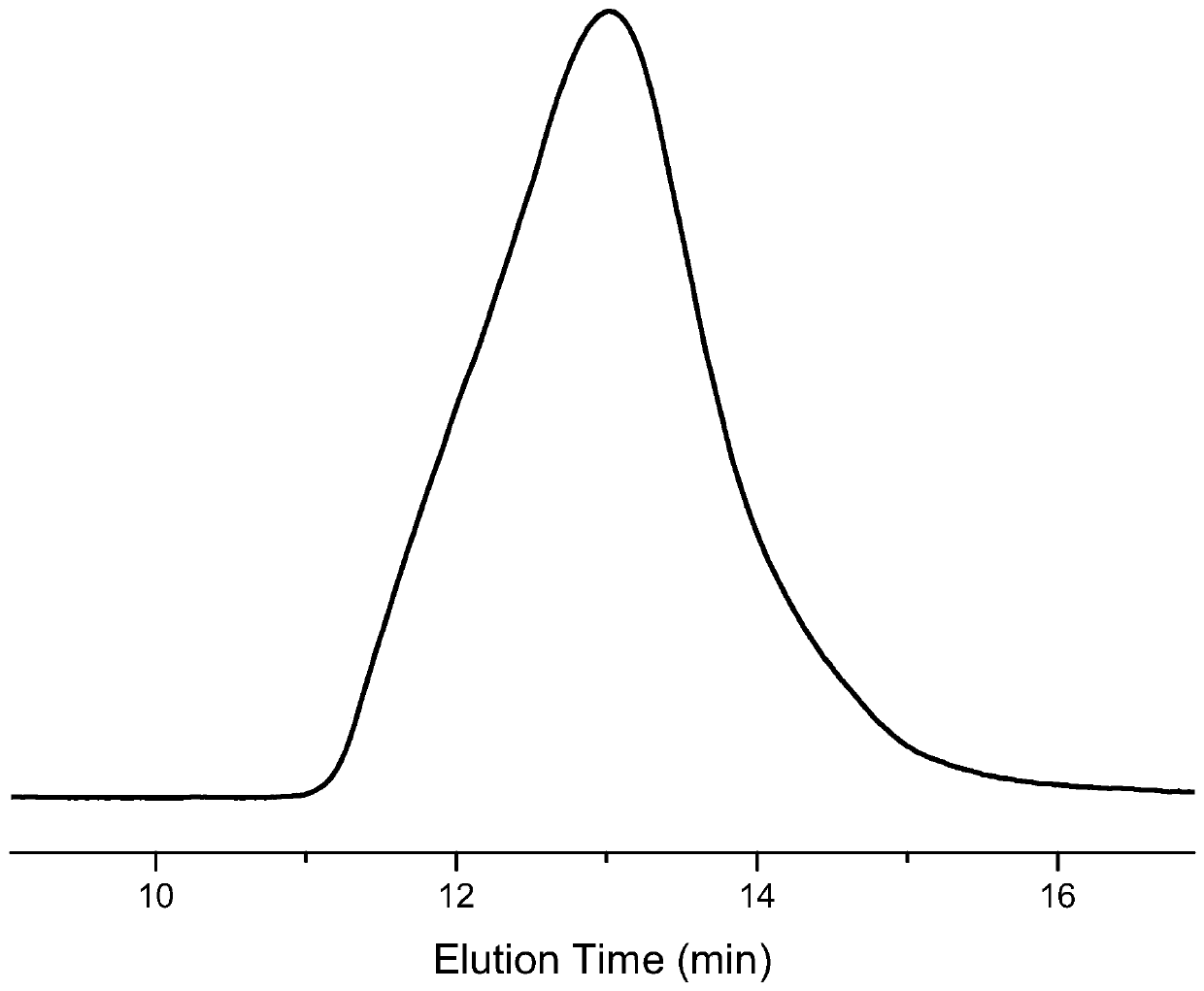

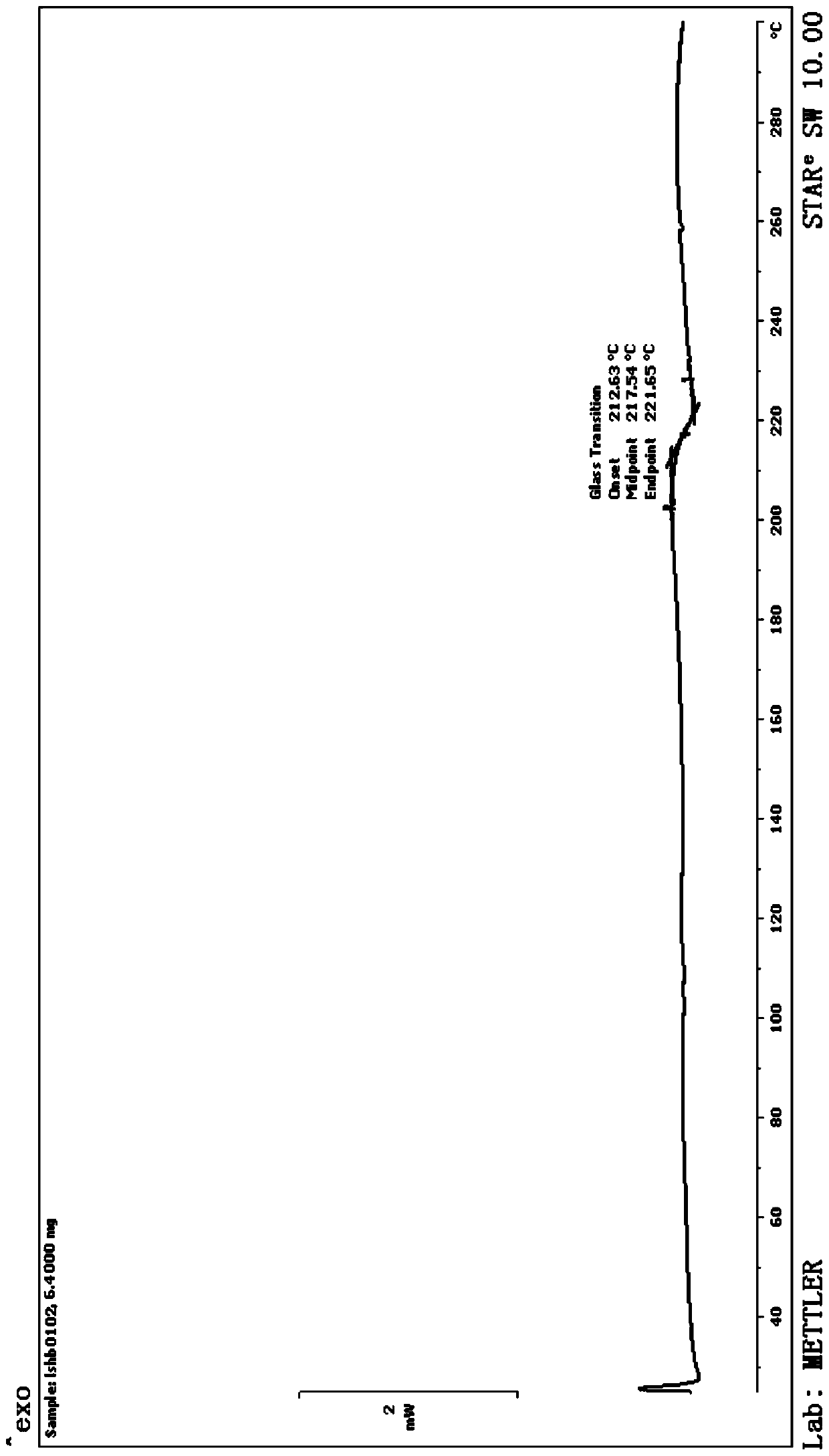

[0095] Gained polymkeric substance is through proton nuclear magnetic resonance spectrum, carbon spectrum, elemental analysis characterizes, shows maleic anhydride-styrene copolymer, maleic anhydride content 49.8mol%, Mw=129.4 * 10 4 g / mol, PDI = 1.36, Tg = 214.2.

Embodiment 2~31

[0097] Referring to Tables 1-4, Tables 1-4 are the polymerization conditions of Examples 1-31. Embodiments 2-31 except the conditions described in the table, other polymerization conditions are identical with embodiment 1.

[0098] Table 1

[0099]

[0100] PS: polymerization temperature, 50°C; polymerization time, 3.5 hours; amount of Lewis acid, 0.1 mmol.

[0101] Table 2

[0102]

[0103] PS: maleic anhydride, 3.6mmol; styrene, 3.6mmol; 100μAlEt 3 , 0.1 mmol.

[0104] table 3

[0105]

[0106]

[0107] PS: Tri-n-octyl aluminum AlOctly 3 The dosage is 0.1 mmol; the polymerization temperature is 50° C.; the polymerization time is 3.5 hours.

[0108] Table 4

[0109] Example Comonomer Yield(g) Conv.(%) M n (×10 4 )

m w (x10 4 )

m w / M n

T g (℃)

26 a 0.596 76.6 92.4 134.0 1.45 – 27 b 0.628 75.7 104.2 142.8 1.37 – 28 c 0.714 85.3 135.9 184.8 1.36 204 29 d 0.232 26.0 89.8 137.4 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com