Intrinsic thermoplastic thiophene derivative copolymer heat-conducting material as well as preparation method and application thereof

A technology of thiophene derivatives and thermally conductive materials, applied in the field of thermally conductive polymer materials, can solve the problems of harsh processing technology, narrow application range, single shape of high thermal conductivity materials, and achieve balanced and stable mechanical properties, mild preparation conditions, and fewer material defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

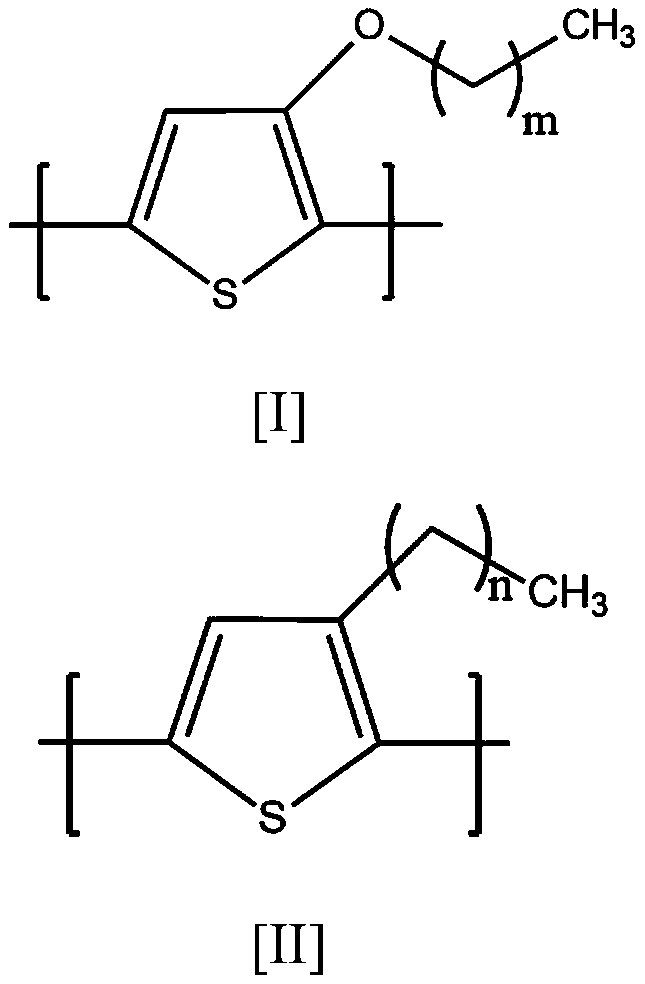

[0032] (1) Weigh 11.4g of 3-methoxythiophene, 10g of n-pentanol, and 0.12g of sodium bisulfate and add them to a three-necked flask equipped with a magnetic stirrer, a thermometer, and a reflux condenser. React for 3 hours, cool to room temperature, and pour into saturated sodium chloride solution. Then the solution was transferred to a separatory funnel, and the organic layer was separated, and the obtained light yellow liquid was 3-pentoxythiophene.

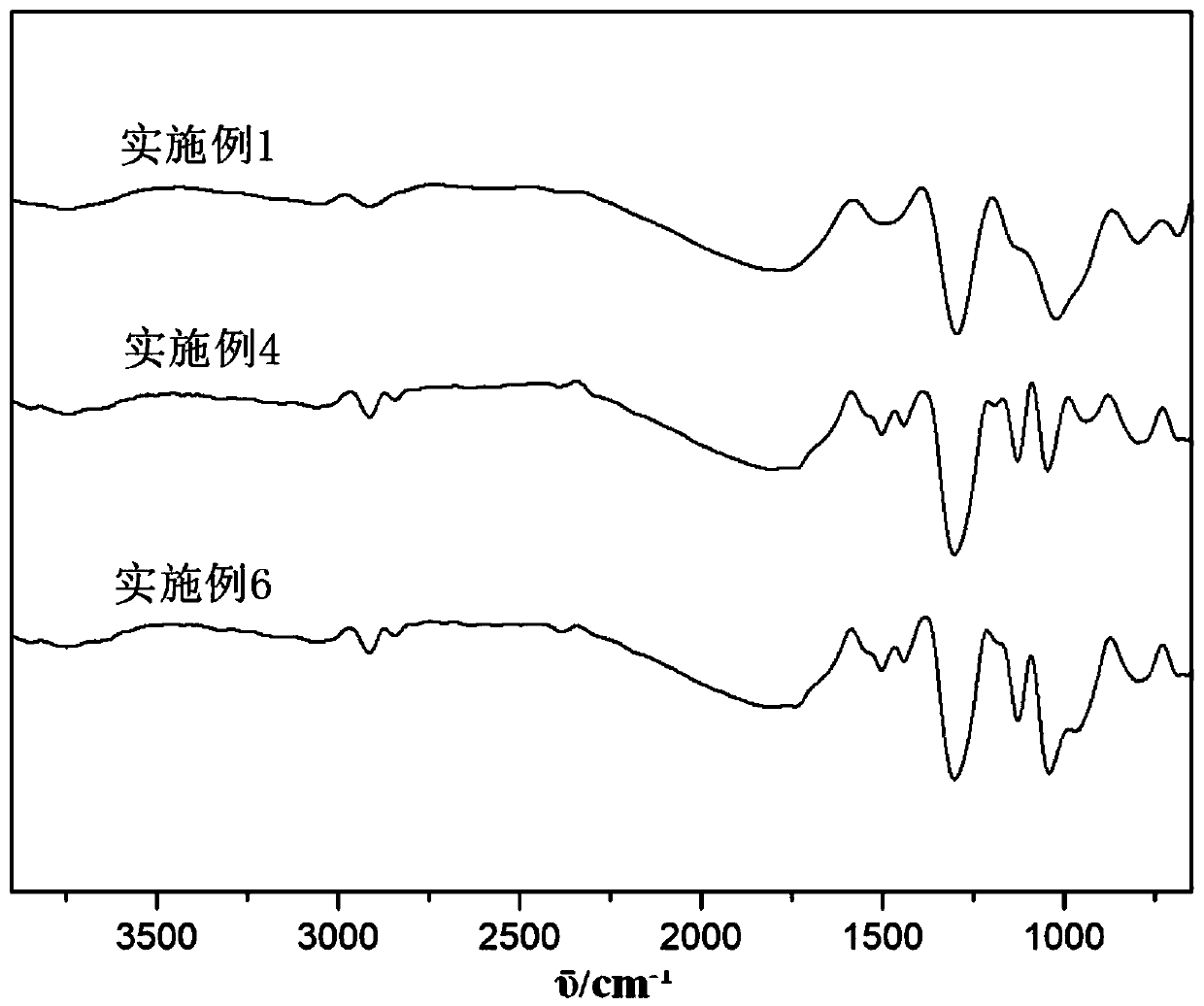

[0033] Gained 3-pentoxythiophene structural formula is: Its H NMR spectrum is as figure 1 shown.

[0034] (2) Put 0.02mol 3-pentyloxythiophene, 0.08mol 3-hexylthiophene, 0.25mol ferric chloride, and 100ml chloroform in a three-necked flask, and under the protection of nitrogen flow, carry out a copolymerization reaction at a constant temperature of 25°C for 24 hours, then Turn off the nitrogen, pour the solution into 500ml of methanol and let it stand for 30min. After suction filtration, the resulting solid was placed in a...

Embodiment 2

[0040] (1) Take by weighing 16.4g 3-methoxythiophene, 13.95g n-amyl alcohol, 0.173g sodium bisulfate and join in the three-necked flask that magnetic stirrer, thermometer, reflux condenser are housed, under the protection of nitrogen stream 115 °C for 3 hours, cooled to room temperature, and poured into saturated sodium chloride solution. Then the solution was transferred to a separatory funnel, and the organic layer was separated, and the obtained light yellow liquid was 3-pentoxythiophene.

[0041] Gained 3-pentoxythiophene structural formula is: Its H NMR spectrum is as figure 1 shown.

[0042] (2) Put 0.03mol 3-pentyloxythiophene, 0.07mol 3-hexylthiophene, 0.28mol iron sulfate, and 120ml toluene in a three-necked flask, and under the protection of nitrogen flow, carry out a copolymerization reaction at a constant temperature of 30°C for 26 hours, then shut down Nitrogen, the solution was poured into 600ml of methanol and allowed to stand for 30min. After suction filtr...

Embodiment 3

[0047] (1) Weigh 22.8g of 3-methoxythiophene, 20g of n-pentanol, and 0.26g of potassium bisulfate into a three-necked flask equipped with a magnetic stirrer, a thermometer, and a reflux condenser, and place them at 120°C under the protection of a nitrogen stream. React for 4 hours, cool to room temperature, and pour into saturated sodium chloride solution. Then the solution was transferred to a separatory funnel, and the organic layer was separated, and the obtained light yellow liquid was 3-pentoxythiophene.

[0048] Gained 3-pentoxythiophene structural formula is: Its H NMR spectrum is as figure 1 shown.

[0049] (2) Put 0.04mol 3-pentyloxythiophene, 0.06mol 3-hexylthiophene, 0.30mol ferric nitrate, and 130ml chloroform in a three-necked flask, and under the protection of nitrogen flow, carry out a copolymerization reaction at a constant temperature of 35°C for 28 hours, then shut down Nitrogen, the solution was poured into 650ml of methanol and allowed to stand for 30mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com