Broad-spectrum antiviral bactericidal paper and application thereof

A technology of anti-virus and sterilizing paper, which is applied in the field of papermaking, can solve the problems of lack of anti-virus and sterilizing functions, and achieve the effect that is beneficial to the health of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

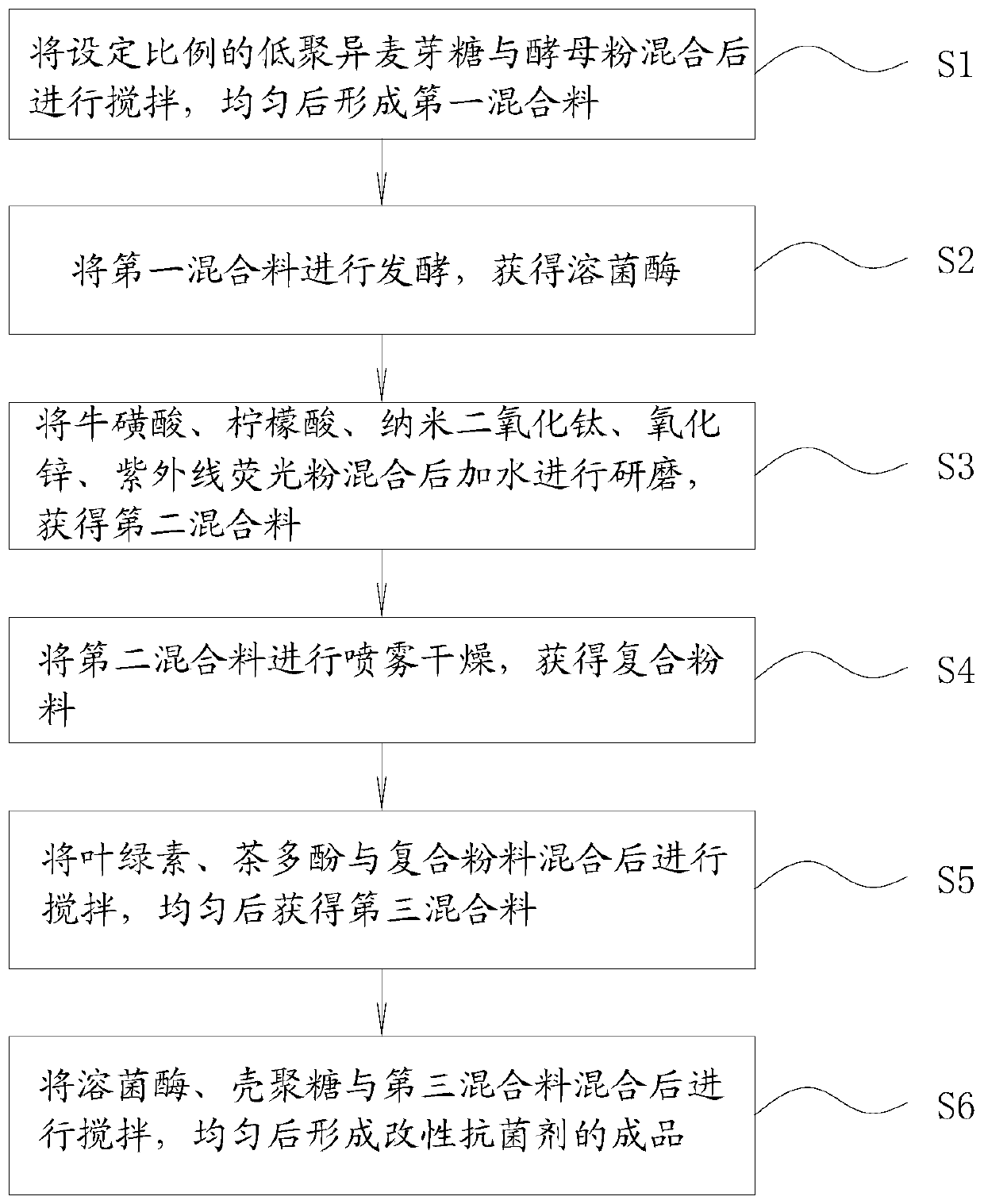

[0035] The preparation method of this modified antimicrobial agent, see attached figure 1 , including the following steps:

[0036] S1: Mix the isomaltooligosaccharide and the yeast powder in a set ratio and then stir to form the first mixture after being uniform;

[0037] S2: fermenting the first mixed material to obtain lysozyme;

[0038] S3: mixing taurine, citric acid, nano-titanium dioxide, zinc oxide, and ultraviolet fluorescent powder, adding water and grinding to obtain a second mixture;

[0039] S4: Spray drying the second mixture to obtain a composite powder;

[0040] S5: Stir after mixing the chlorophyll, tea polyphenols and the composite powder, and obtain the third mixture after uniformity;

[0041] S6: After mixing the lysozyme, chitosan and the third mixture, stirring, and uniformly forming a finished product of the modified antibacterial agent.

[0042] Further, step S2 specifically includes: fermenting the first mixed material in a stainless steel fermente...

Embodiment 1

[0046] S1: Mix 12 parts of isomalto-oligosaccharide and 0.9 part of yeast powder and then stir to form the first mixture;

[0047] S2: ferment the first mixed material in a stainless steel fermentation tank to obtain lysozyme; the fermentation time is controlled at 168 hours;

[0048] S3: After mixing 10 parts of taurine, 0.9 parts of citric acid, 38 parts of nano-titanium dioxide, 4 parts of zinc oxide, and 4.5 parts of ultraviolet fluorescent powder, add pure water to grind in a sander to obtain the second mixture; the grinding time is 3 hours;

[0049] S4: Spray drying the second mixture to obtain a composite powder;

[0050] S5: Mix 9 parts of chlorophyll, 9 parts of tea polyphenols with the composite powder and stir to obtain a third mixture;

[0051] S6: Mix lysozyme, 6 parts of chitosan and the third mixture, then stir, and evenly form a finished product of the modified antibacterial agent.

Embodiment 2

[0053] S1: Mix 10 parts of isomaltooligosaccharide and 1 part of yeast powder and then stir to form the first mixture;

[0054] S2: ferment the first mixed material in a stainless steel fermentation tank to obtain lysozyme; the fermentation time is controlled at 168 hours;

[0055] S3: After mixing 10 parts of taurine, 1 part of citric acid, 40 parts of nano-titanium dioxide, 5 parts of zinc oxide, and 5 parts of ultraviolet fluorescent powder, add pure water to grind in a sander to obtain the second mixture; the grinding time is 3 hours;

[0056] S4: Spray drying the second mixture to obtain a composite powder;

[0057] S5: Mix 10 parts of chlorophyll, 10 parts of tea polyphenols with the composite powder and then stir to obtain the third mixture;

[0058] S6: Mix lysozyme, 8 parts of chitosan and the third mixture and then stir to form a finished product of the modified antibacterial agent after uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com