Liquid concentrate for seasoning, wood piece usable as fermentation index for seasoning, kit for manufacturing seasoning, method for manufacturing seasoning, seasoning, and thickened seasoning

A manufacturing method and technology of seasonings, which are applied in food ingredients as odor improvers, food ingredients as taste improvers, climate change adaptation, etc., can solve the problems of consumer palatability, different flavors, poor yeast growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0365] [1. Various methods]

[0366] 1-1. Determination method of reducing sugar

[0367] The content of reducing sugar in the stock solution for seasoning and liquid seasoning can be measured as the content of direct reducing sugar by the method described in the document "Japanese Agriculture and Forestry Standards for Soy Sauce" (pronounced by the Ministry of Agriculture, Forestry and Fisheries of Japan).

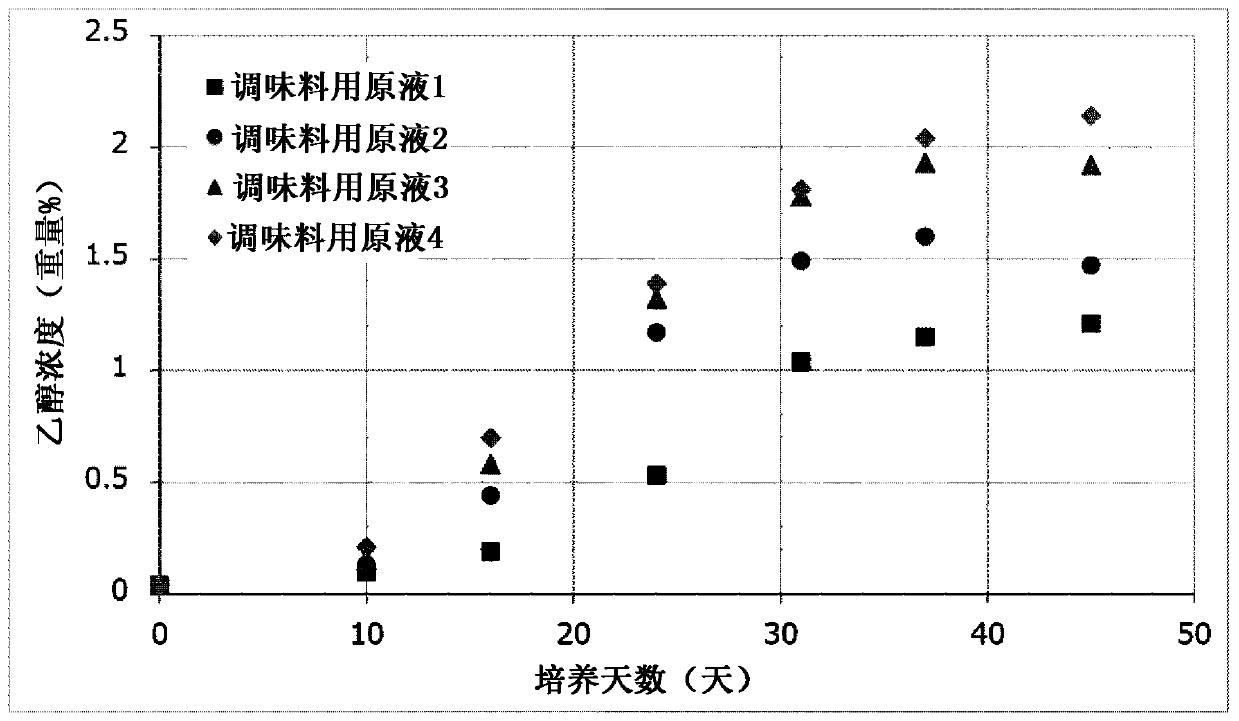

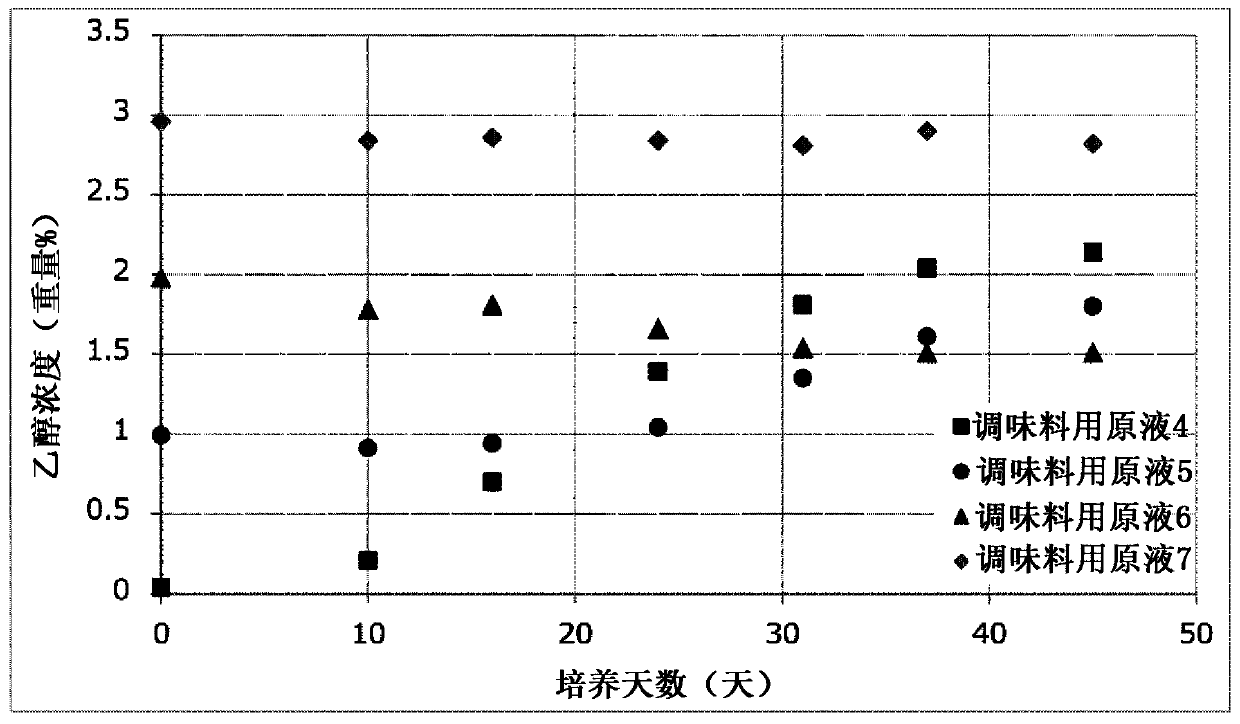

[0368] 1-2. Determination method of ethanol

[0369] The ethanol content in the stock solution for seasonings and liquid seasonings was measured by GC-FID under the following conditions according to a conventional method.

[0370]

[0371] Measuring device: GC-2014AF (manufactured by Shimadzu Corporation)

[0372] Column: porapack q (80-100mesh) (manufactured by GL Sciences, Inc.)

[0373] Injection port temperature: 230°C

[0374] Temperature condition: hold at 155°C (7 minutes)

[0375] Carrier gas: nitrogen

[0376] Column flow: 20mL / min

[0377] Detector temp...

Embodiment 2

[0475] [1. Evaluation of sinkability and floatability of wood chips]

[0476] 1-1: Evaluation of sedimentation properties of wood chips in stock solution for seasoning

[0477] (1) Manufacturing method of stock solution for seasoning

[0478] Inoculate into a 6:4 mixture of cooked whole soybeans and cracked roasted wheat Aspergillus sojae The kind of koji was prepared according to conventional methods for 43 hours to obtain soy sauce koji.

[0479] Add 100 parts by mass of the obtained soy sauce koji to 116 parts by mass of salt water (salt concentration 25% (w / v)), then add soy sauce lactic acid bacteria (Tetragenococcus halophilus), and stir at 15 to 25° C. Lactic acid fermentation was carried out for 20 days in a conventional method. Solid-liquid separation is performed on the soy sauce mash after lactic acid fermentation, and the liquid juice is treated with a UF membrane to obtain a stock solution for seasoning with a specific gravity (g / ml) of 1.207.

[0480] (2) Ho...

Embodiment 3

[0537] [1. Evaluation of the influence of the color number of the seasoning on the observation of wood chips used as an index for fermentation]

[0538] 1-1. Preparation of liquid seasonings 8-12

[0539] Dilute commercially available soy sauce "Kyushu さしみあまくち" (manufactured by Kikkoman Co., Ltd.) with water to adjust the color number to No. 5 (liquid seasoning 8), No. 10 (liquid seasoning 9), and No. 15 (liquid seasoning 10 ), No. 20 (Liquid Seasoning 11) and No. 30 (Liquid Seasoning 12).

[0540] 1-2: Discrimination evaluation of wood chips

[0541] Pour 8 to 12 150ml of liquid seasoning into a 150ml table top bottle (manufactured by Daiichi Glass Co., Ltd.), and settle 3 bottles. The volume described in 5-1 above is 1cm 3 fir tree slices 1 . For the settled wood chips, visually observe the container containing the seasoning from a fixed observation point. If all the wood chips can be distinguished, then the evaluation is "○", if 1 to 2 wood chips can be distinguished, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com