Tannin-rich seasoned flour product with long shelf life and preparation method thereof

A technology for noodle products and shelf life, which is applied in the field of seasoned noodle products rich in tannins and has a long shelf life and the preparation thereof, can solve the problems such as the total number of bacterial colonies exceeding the standard, affecting product quality, and great environmental protection pressure, and achieving increased commercial value and promotion. Product quality, tannin content improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

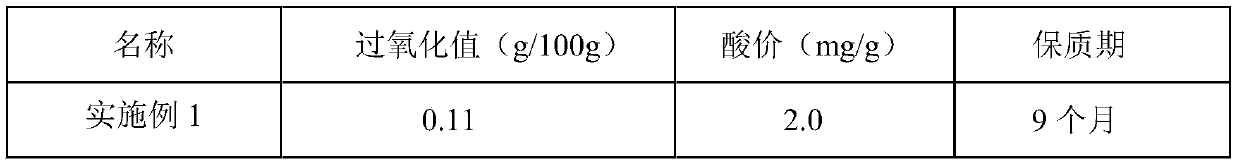

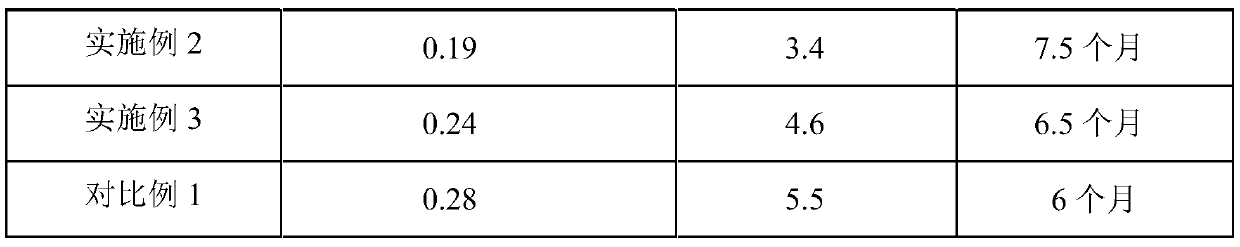

Embodiment 1

[0035] This embodiment provides a seasoned noodle product rich in tannin and with a long shelf life and a preparation method thereof.

[0036] The concrete preparation method of seasoning flour product is as follows:

[0037] 1) Mix salt, monoglyceride and water evenly, and then add them to medium-gluten wheat flour for powdering to obtain a flour flocculation mixture;

[0038] 2) Extruding and maturing the flour flocculation mixture to obtain a semi-finished seasoned noodle product;

[0039] 3) drying the white grape marc with a spray freeze-drying technique to obtain a powder substance;

[0040] 4) Sieve the powder material respectively to obtain the powder material with target particle size;

[0041] 5) Dissolving the powder substance with the target particle size in the cyclodextrin saturated solution to form a mixed solution, and then mixing it with vegetable oil to obtain a mixed oil substance;

[0042] 6) Mix the semi-finished seasoned noodle product, spices and mixe...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is:

[0046]Wherein, in step 5), the powdered substance is dissolved in a saturated solution of β-cyclodextrin, and the concentration of the mixed solution is 3g / 100mL. In step 6), in parts by weight, the mixed oil substance is 6.5 parts.

[0047] Other each process step, process parameter and each raw material and consumption are all identical with embodiment 1.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is:

[0050] Wherein, in step 3), the conditions of the spray freeze-drying technique are as follows: the freezing temperature is -50° C., the nozzle diameter is 1.8 mm, and the slurry atomization pressure is 2.0 MPa. In step 5), the powdered substance is dissolved in a saturated solution of α-cyclodextrin, and the concentration of the mixed solution is 2.5g / 100mL. In step 6), in parts by weight, the mixed oil substance is 6 parts.

[0051] Other each process step, process parameter and each raw material and consumption are all identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com