Comprehensive recycling device and method for asphalt pavement resources

A technology of asphalt pavement and recycling equipment, which is applied in chemical instruments and methods, transportation and packaging, flotation, etc., and can solve problems such as poor aggregate performance, high water absorption rate, and secondary aging of asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

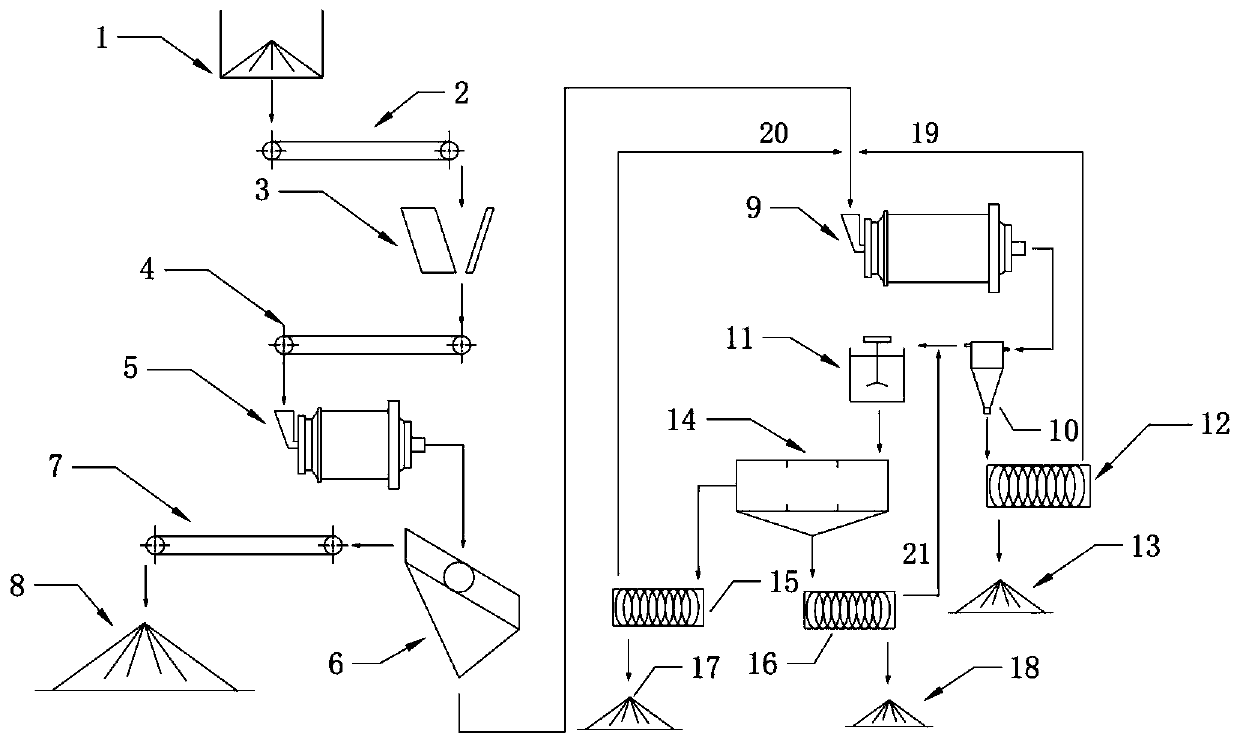

Method used

Image

Examples

Embodiment 1

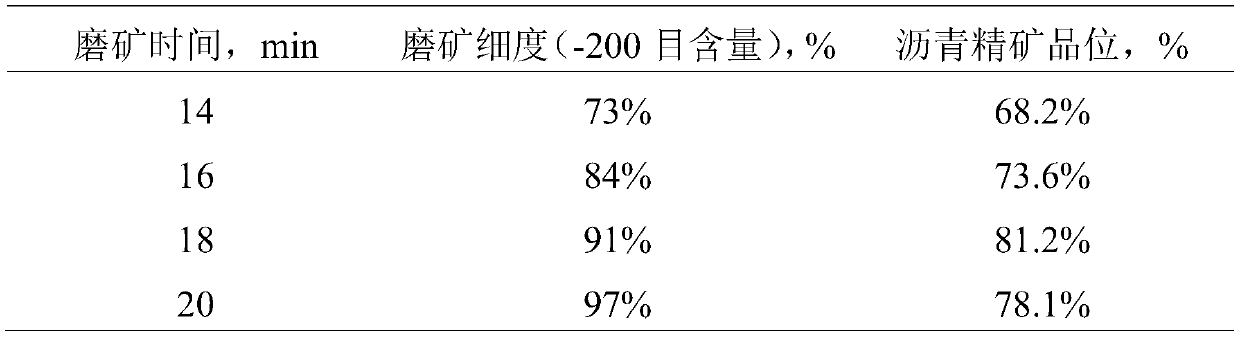

[0041] The asphalt concrete excavated on the road around the city in a certain city mainly contains gravel, sand, mineral powder, asphalt, and soil. Technological process: first feed the asphalt concrete into the silo 1, the silo is connected to the mining machine 2, use the mining machine 2 to feed the asphalt concrete into the jaw crusher 3, and crush the asphalt concrete to -300mm to obtain crushed products, crushed products The crushed products are fed into the self-grinding machine through the belt conveyor 4 to grind the crushed products. The ore discharge granularity is -10mm to obtain the ore pulp. The ore pulp is sieved through a linear vibrating screen with a sieve diameter of 12mm, and the coarse-grained bone is obtained after sieving. The two products of material and undersize slurry, the coarse-grained aggregate is given to the coarse-grained aggregate product stockpile 8 through the coarse-grained aggregate product conveying belt 7. The under-screen slurry is fur...

Embodiment 2

[0043] The asphalt concrete of the abandoned bridge pavement in a certain city mainly contains gravel, sand, mineral powder, asphalt and soil. Technological process: first feed the asphalt concrete into the silo 1, the silo is connected to the feeder 2, use the feeder 2 to feed the asphalt concrete into the jaw crusher 3, and use the jaw crusher 3 to crush the asphalt concrete to -250mm , to obtain crushed products, the crushed products are ground by self-grinding machine, the ore discharge granularity is -8mm, and the ore pulp is obtained, and the ore pulp is screened through a linear vibrating screen with a sieve diameter of 10mm, and coarse-grained bone is obtained after screening. The two products of material and undersize slurry, the coarse-grained aggregate is given to the coarse-grained aggregate product stockpile 8 through the coarse-grained aggregate product conveying belt 7. The material under the screen is further ground and stripped by ball mill 9, the grinding fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com