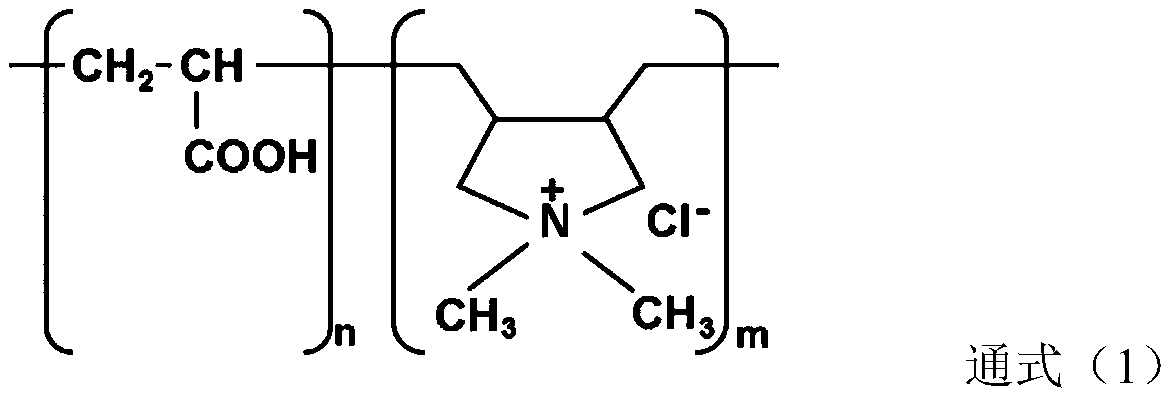

Liquid skin cleanser composition

A skin cleanser and composition technology, applied in the field of liquid skin cleanser compositions, can solve the problems of non-discharge, poor discharge, and poor skin moist feeling, and achieve good discharge, excellent moist feeling, and good low-temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

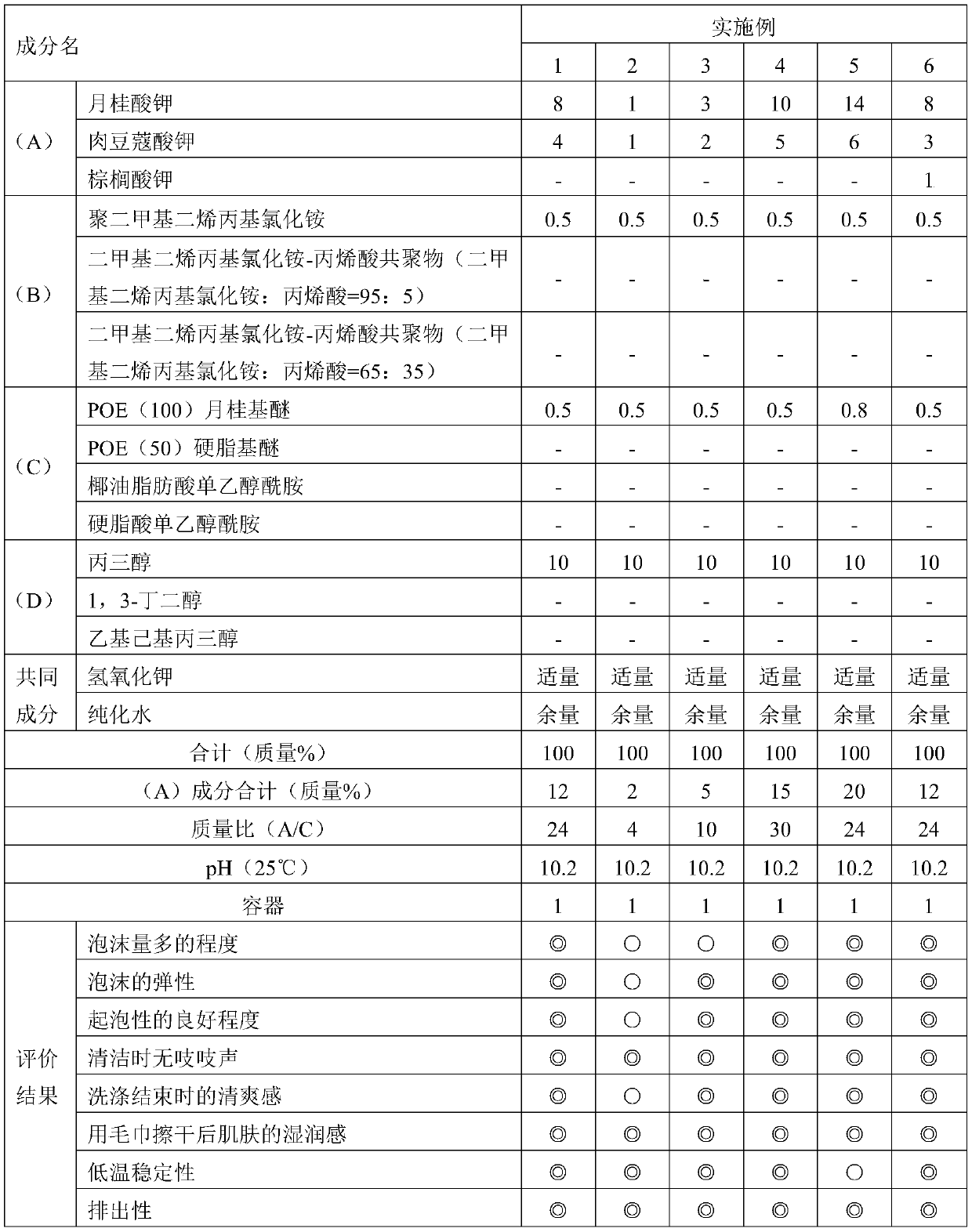

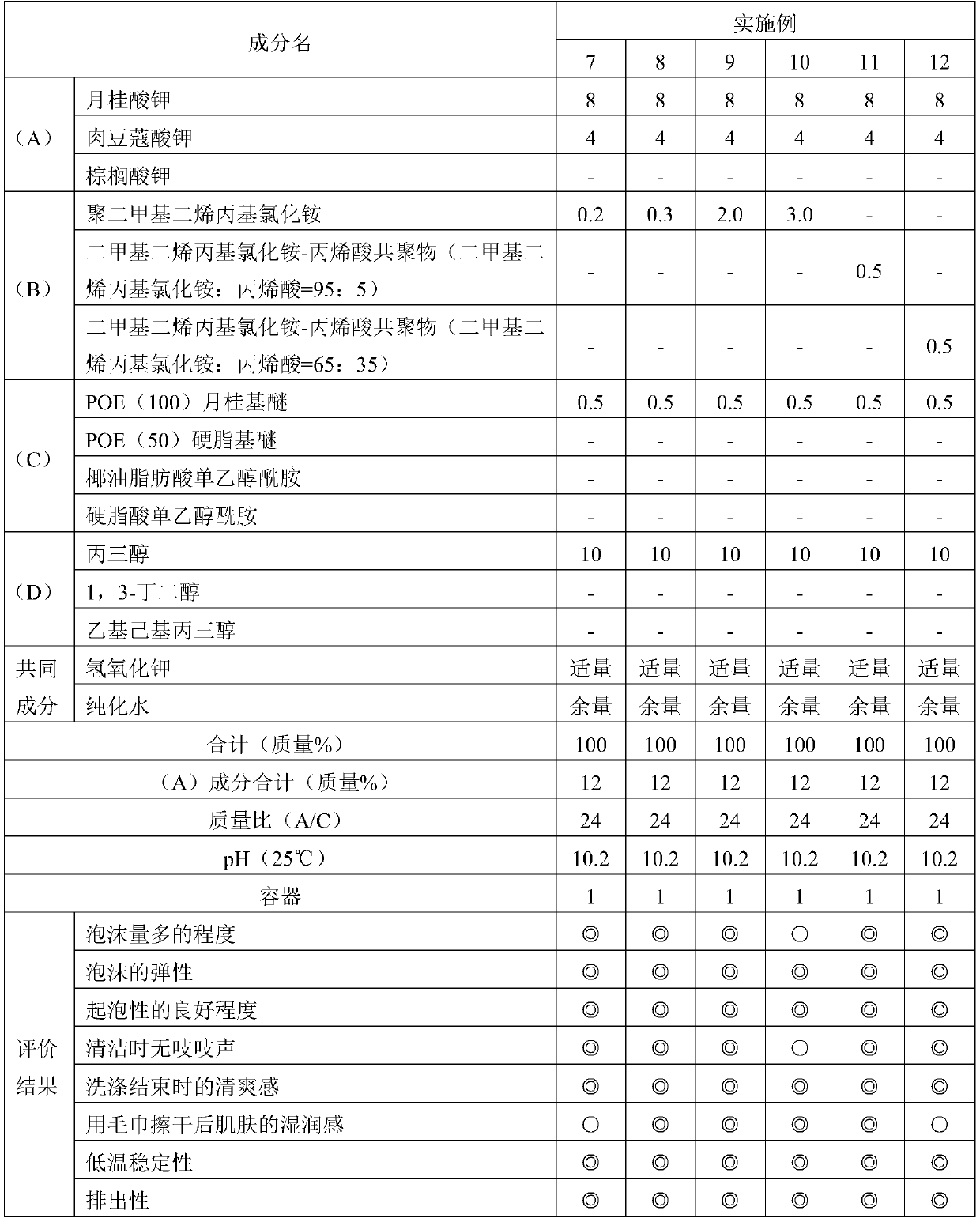

Embodiment 1~33 and comparative example 1~12

[0111] Liquid skin cleansing compositions having the compositions and contents shown in Tables 1 to 8 below were produced by a usual method. Specifically, it was produced by the following method.

[0112] Heat the purified water to 70°C to 80°C, dissolve the higher fatty acid salt of (A) component or (A) comparative component and the polyol of (D) component, cool to below 40°C, and then add (B) component Cationic polymer or (B) comparative component and (C) nonionic surfactant of component or (C) comparative component to produce a liquid skin cleanser composition, the amount of the composition being the final liquid skin cleanser 95% by mass of the total amount of the composition. Afterwards, when the predetermined pH was not satisfied, potassium hydroxide was added as a common component to adjust to the predetermined pH, and then purified water was added to make the total amount 100% by mass to obtain the intended liquid skin cleanser composition. In addition, a propeller w...

Embodiment 34~43

[0237] Heat purified water to 70°C to 80°C, dissolve the higher fatty acid salt of (A) component and the polyhydric alcohol of (D) component, cool to below 40°C, then add the cationic polymer of (B) component, (C ) component nonionic surfactant and (E) the amidopropyl betaine of component, thereby manufacture liquid skin cleanser composition, the amount of this composition is 95% of the total amount of liquid skin cleanser composition finally obtained quality %. After that, when the predetermined pH was not satisfied, potassium hydroxide was added as a common component to adjust to the predetermined pH, and then purified water was added so that the total amount became 100% by mass to obtain the target liquid skin cleanser composition. In addition, a propeller was used as a stirring blade, and a three-in-one stirrer (Three one motor) (HEIDONBL1200, manufactured by Shinto Chemical Co., Ltd.) was used for stirring. In addition, pH was measured at 25° C. using a pH meter (HM-30R ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com