Long-acting anticoagulant coating for in-vitro membrane oxygenation device (ECMO) and preparation method thereof

An anticoagulant and oxygenation technology, applied in the field of biomedical engineering functional materials, can solve the problems of loss of anticoagulant activity of heparin units, reduction of heparin surface assembly amount and activity, and limitation of clinical long-term anticoagulant effect, so as to benefit endothelial Enhanced, increased stability, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

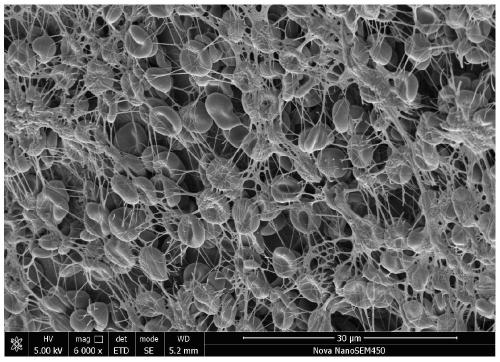

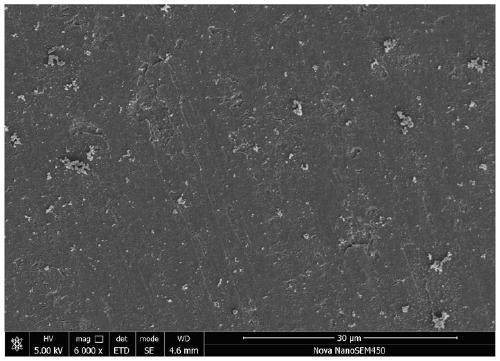

Image

Examples

Embodiment 1

[0030] A method for preparing a long-acting anticoagulant coating that can be used in the whole system of an extracorporeal membrane oxygenation device (ECMO), is prepared by the principle of film formation-crosslinking-film formation, and specifically includes the following steps:

[0031] (1) The polyurethane catheter of the ECMO device is pretreated with an aminosilane coupling agent, so that the surface of the material carries amino functional groups;

[0032] (2) Put the above material in 3 mg / mL heparin buffer solution (pH5.5), react for 10 minutes, wash with deionized water for 3 times, then place the material in 0.5 mg / mL polyethyleneimine solution Medium (pH6), after reacting for 10min, wash with deionized water for 3 times and put it into 3mg / mL heparin buffer solution (pH5.5) again to complete a cycle step, then use it as the base material, repeat this step 4 Coating A is obtained after the times;

[0033] (3) The obtained coating A is treated with 0.2%wt glutarald...

Embodiment 2

[0036] A method for preparing a long-acting anticoagulant coating that can be used in the whole system of an extracorporeal membrane oxygenation device (ECMO), is prepared by the principle of film formation-crosslinking-film formation, and specifically includes the following steps:

[0037] (1) The neodymium alloy of the centrifugal pump head of the ECMO device is pretreated by ammonia plasma, so that the surface of the material carries amino functional groups;

[0038] (2) above-mentioned material is placed in the heparin buffer solution (pH6) of 0.5mg / mL, use after reaction 20min, wash 3 times with deionized water, then material is placed in the chitosan solution of 0.2mg / mL ( pH 6), after reacting for 10 minutes, washed with deionized water for 3 times, and then placed in 0.5 mg / mL heparin buffer solution (pH 6) to complete a cycle step, and then use it as the base material, repeat this step 5 times to obtain coating A;

[0039] (3) Gained coating A is treated with 0.2%wt ...

Embodiment 3

[0042]A method for preparing a long-acting anticoagulant coating that can be used in the whole system of an extracorporeal membrane oxygenation device (ECMO), is prepared by the principle of film formation-crosslinking-film formation, and specifically includes the following steps:

[0043] (1) The polyurethane catheter of the ECMO device is pretreated with an aminosilane coupling agent, so that the surface of the material carries amino functional groups;

[0044] (2) Put the above material in 5mg / mL heparin buffer solution (pH7), react for 30min, wash with deionized water for 3 times, then place the material in 1mg / mL polylysine solution (pH6 ), after reacting for 10 minutes, washed with deionized water for 3 times and then placed in 5 mg / mL heparin buffer solution (pH 7) to complete a cycle step, then use it as the base material, repeat this step 5 times to obtain a coating A;

[0045] (3) The genipin of gained coating A is processed 10min with 0.3%wt;

[0046] (4) Using co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com