A kind of method that utilizes metal organic framework fe(nic) to activate persulfate with high efficiency to treat organic wastewater

A metal-organic framework and activated persulfate technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problem of insufficient content of iron-based MOFs, low structure-effectiveness, and catalytic persulfate Poor activity and other problems, to achieve the effect of strong activity, good structure and performance, and high content of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

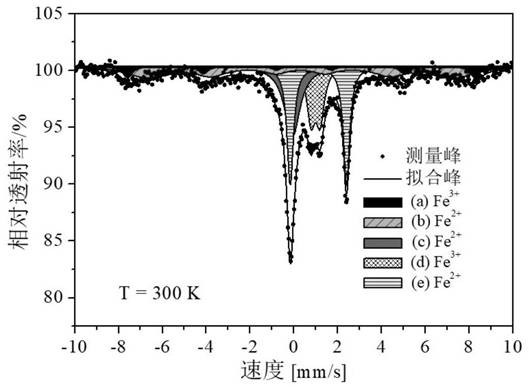

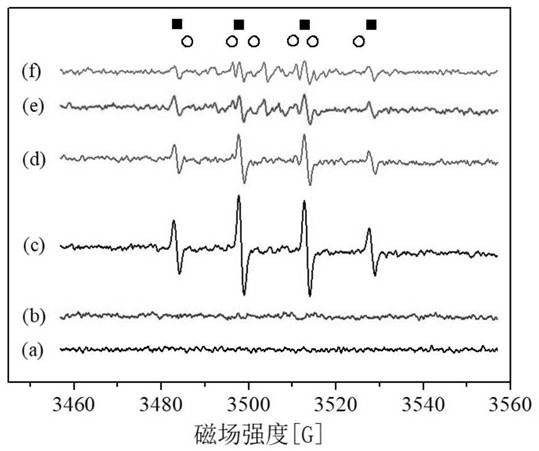

Method used

Image

Examples

Embodiment 1

[0039] Metal-organic framework Fe(Nic) activates PS to treat sulfamethoxazole (SMX) simulated wastewater. The specific operation steps are as follows:

[0040] (1) Preparation of the catalyst: Weigh 234mg (0.625mmol) of [Fe(Cp)(CO) 2 ] 2 and 310 mg (2.5 mmol) of HNic were poured into 35 mL of CH 3 CN / H 2 In a mixed solvent of O (v / v=4 / 3), stir for 2 h to mix well. The precursor solution was poured into a 100mL polytetrafluoroethylene-lined autoclave, and placed in an electric thermostat blast drying oven preheated to 160°C. After 48 hours, the reactor was taken out and cooled to room temperature naturally. Filter to separate the solid from the liquid, and simultaneously wash the solid alternately with methanol and deionized water. Finally, the above solid was dried in a vacuum oven at 85° C. for 48 hours to obtain the metal organic framework Fe(Nic).

[0041] (2) Degradation of SMX simulated wastewater: 250mL Erlenmeyer flask was used as the reaction bottle to prepare si...

Embodiment 2

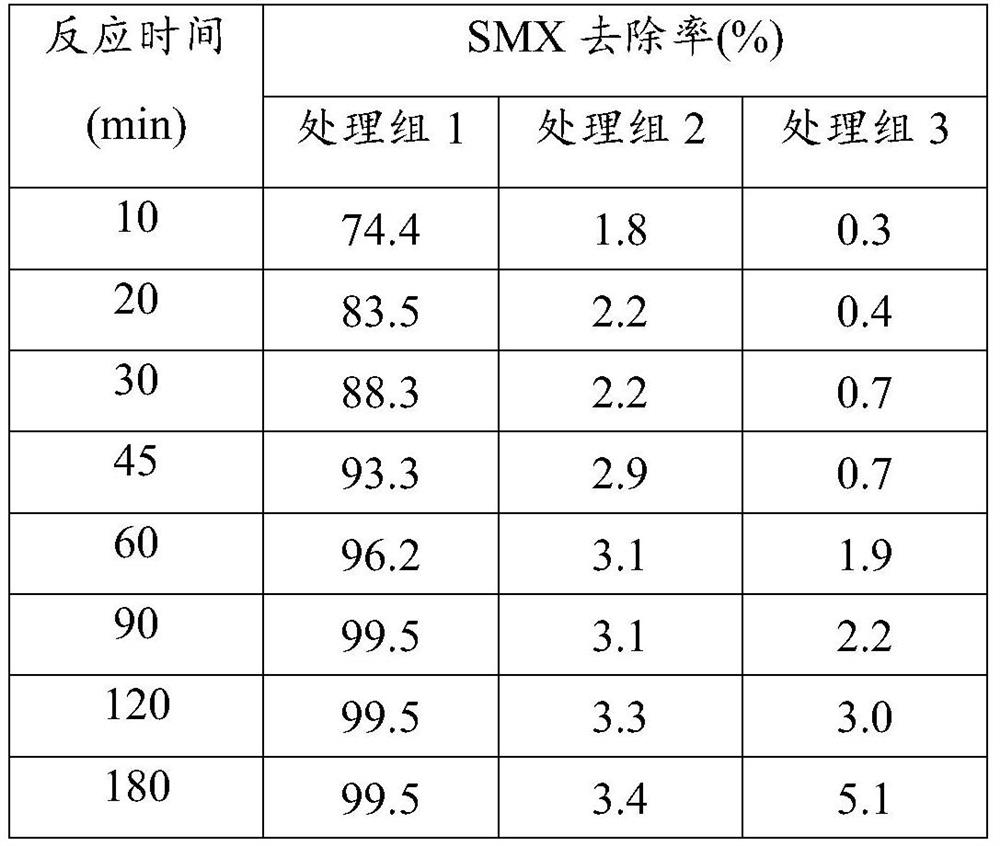

[0047] With the Fe(Nic) prepared in Example 1 as catalyst, PS as oxidant, the initial concentration of SMX simulated wastewater is 10mg / L, without adjusting the pH of wastewater, four treatment groups are set: after adding 0.475g / L sodium persulfate, respectively Add ferrous metal organic framework catalyst 0.1g / L (treatment group 1), 0.3g / L (treatment group 2), 0.5g / L (treatment group 3), 1.0g / L (treatment group 4), under 25 ℃ 180rpm constant temperature shaking shaker fully stirred for reaction, reaction 5min, 10min, 20min, 30min, 45min, 60min, 90min, 120min and 180min respectively sampling and determination of SMX residual concentration value, the results are shown in the table 2.

[0048] Table 2

[0049]

[0050] The results in Table 2 show that the dosage of Fe(Nic) has an effect on the efficiency of activating PS to oxidize and degrade SMX simulated wastewater. Within a certain range, the SMX degradation rate increases with the increase of the catalyst dosage: when...

Embodiment 3

[0052] Adopt 250mL Erlenmeyer flask as reaction bottle, preparation initial concentration is the SMX simulated waste water of 10mg / L, with the Fe(Nic) that embodiment 1 prepares as catalyst, PS is oxygenant, does not adjust waste water pH, arranges five treatment groups: respectively In four groups of reaction bottles, add 190mg / L (treatment group 1), 237.5mg / L (treatment group 2), 356.25mg / L (treatment group 3), 475mg / L (treatment group 4), 950mg / L (treatment group Group 5) Sodium persulfate, then add 0.5g / L ferrous metal-organic framework material to all treatment groups, and fully stir the reaction in a constant temperature shaking shaker at 180rpm at 25°C. React for 5min, 10min, 20min, 30min , 45min, 60min, 90min, 120min and 180min respectively took samples and measured the remaining concentration of SMX, and the residual concentration of PS in wastewater was measured at the same time in treatment groups 2 and 4. The results are shown in Table 3.

[0053] table 3

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com