Method for continuous preparing olefin through alcohol dehydration

A technology for alcohol dehydration and olefins, which is applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbon production from oxygen-containing organic compounds, etc., can solve the problems of high energy consumption and low efficiency, and achieve short reaction time and low reaction temperature. , the effect of small flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preparation of sulfonated bamboo charcoal: refer to Xu Qiong, Xia Yue, Yin Dulin, et al. Preparation, characterization and acid catalytic performance of sulfonated bamboo charcoal;

[0023] Preparation of cotton charcoal sulfonic acid: refer to Fan Changling, Xu Zhongyu, Xu Qiong, et al. Preparation, characterization and acid catalytic performance of cotton charcoal sulfonic acid[J]. Carbon, 2009(1).

[0024] Preparation of carbon-based sulfonated solid acid catalysts: Li Baomin, Jiang Lei. Synthesis and catalytic performance of carbon-based sulfonated solid acid catalysts [EB / OL]. Beijing: China Science and Technology Papers Online [2012-02-21].

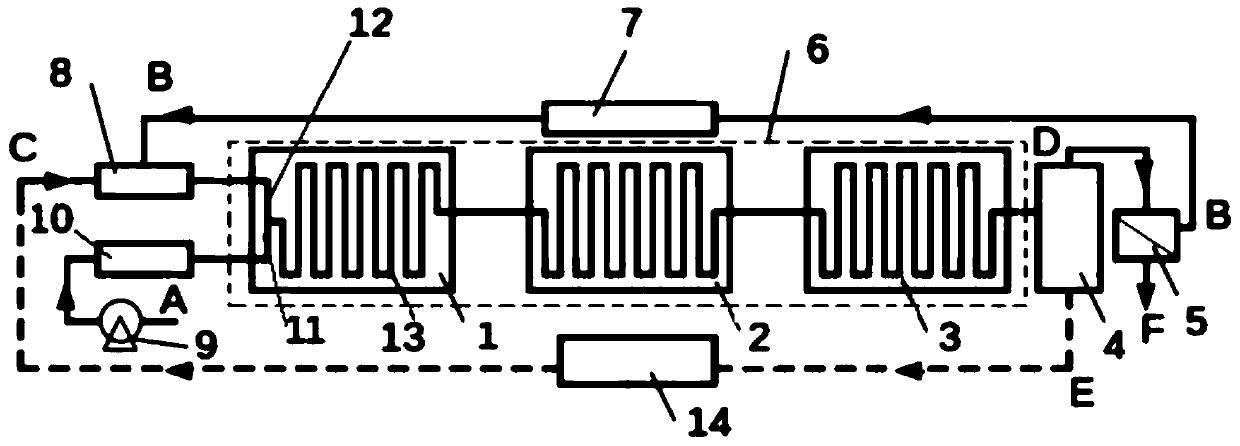

[0025] Alcohol dehydration continuous preparation of olefins device (see figure 1 ) comprises a continuous flow reactor 6, which has three reaction modules: the first reaction module 1, the second reaction module 2 and the third reaction module 3, each reaction module includes a passage for material reaction, for example, the...

Embodiment 1

[0029] A method for continuously preparing olefins by alcohol dehydration (use alcohol dehydration to continuously prepare olefins device, see figure 1 ), including the following steps:

[0030] After the low molecular weight alcohol A (mass concentration is 95% ethanol) passes into the steam generator 10 with the metering pump 9, passes into the first temperature control tube 11 of the first reaction module 1 of the continuous flow reactor 6, so that A The temperature is adjusted to the first set temperature of 70°C; solid dehydrating agent particles (sulfonated bamboo charcoal, particle size between 100 and 200 microns, water absorption efficiency ≥ 30% at room temperature) C pass through the pneumatic conveyor 8 in the carrier gas (nitrogen) Under the action of the second temperature control tube 12 of the first reaction module 1 of the continuous flow reactor 6, the temperature of C and B is adjusted to the first set temperature of 70 ° C; A, B and C are in the first In t...

Embodiment 2

[0032] A method for continuously preparing olefins by alcohol dehydration (using alcohol dehydration to continuously prepare olefins device, see figure 1 ), including the following steps:

[0033]After low molecular weight alcohol (mass concentration is 97% 2-butanol) A passes into steam generator 10 with metering pump 9, passes into the first temperature control tube 11 of the first reaction module 1 of continuous flow reactor 6, The temperature of A is adjusted to 80°C of the first set temperature; solid dehydrating agent particles (cotton charcoal sulfonic acid, particle size between 100~200 microns, water absorption efficiency ≥ 30% at normal temperature) C is loaded by pneumatic conveyer 8 Under the effect of gas (carbon dioxide), pass into the second temperature control tube 12 of the first reaction module 1 of continuous flow reactor 6, make the temperature of C and B be adjusted to the first setting temperature 80 ℃; A, B and C, in the main process 13 of the first rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com