Preparation method of 3, 5-bis (trifluoromethyl) acetophenone

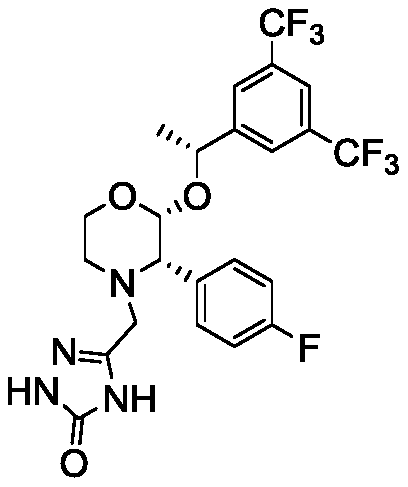

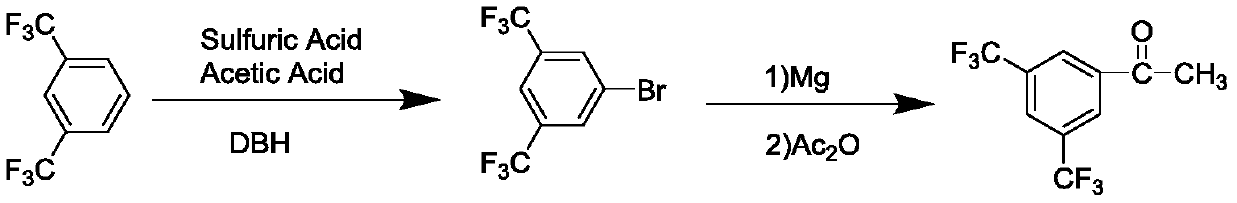

A technology of trifluoromethyl acetophenone and trifluoromethyl bromide, which is applied in the field of organic synthesis and pharmaceuticals, can solve the problems of high cost, long reaction steps, complicated steps, etc., and achieve good social and economic benefits and economic value The effect of high potential and simple reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

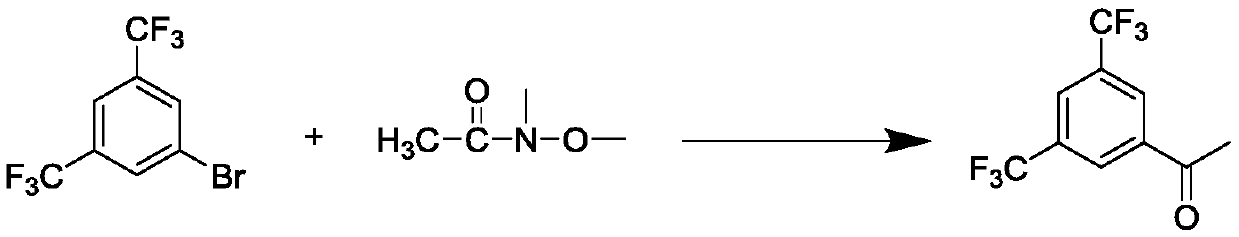

[0030] Its preparation method comprises the following steps:

[0031] Q1, the reaction step, at the reaction temperature, select N-methoxy-N-methylacetamide or N-methoxy-N-methylformamide and 3,5-bistrifluoromethyl bromobenzene, n- Mix butyllithium, stir and react under the condition of reaction solvent, the reaction temperature is -70~-90°C;

[0032] Q2, the post-processing step, raised to room temperature, extracted, washed, dried, and evaporated to remove the residual solvent, separated by column chromatography to obtain 3,5-bistrifluoromethylacetophenone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com