Process for preparing phenylenediamine through micro-reaction technology

A technology of phenylenediamine and micro-reaction, which is applied in the field of preparation of phenylenediamine through micro-reaction technology, which can solve the problems of large heat generation, industrial safety accidents, and large amount of materials, so as to prevent accumulation, controllable process safety, and increase the probability of collision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A process for preparing phenylenediamine through micro-reaction technology, comprising the following steps: metering and continuously feeding nitroaromatics to be reduced, a solvent, a catalyst and hydrogen into a hydrogenation micro-reactor for hydrogenation-reduction reaction.

[0055] The reaction solution obtained in the hydrogenation microreactor enters the hydrogenation aging device for aging, and the end point is when no nitro compounds are detected.

[0056] The nitroaromatics are m-dinitrobenzene.

[0057] The mol ratio of hydrogen and m-dinitrobenzene added in the hydrogenation microreactor is 14:1; the weight ratio of feed is m-dinitrobenzene: solvent (methanol): catalyst (skeleton nickel)=1: 2.5: 0.08; control the temperature in the hydrogenation microreactor to be 60°C and the pressure to be 7MPa.

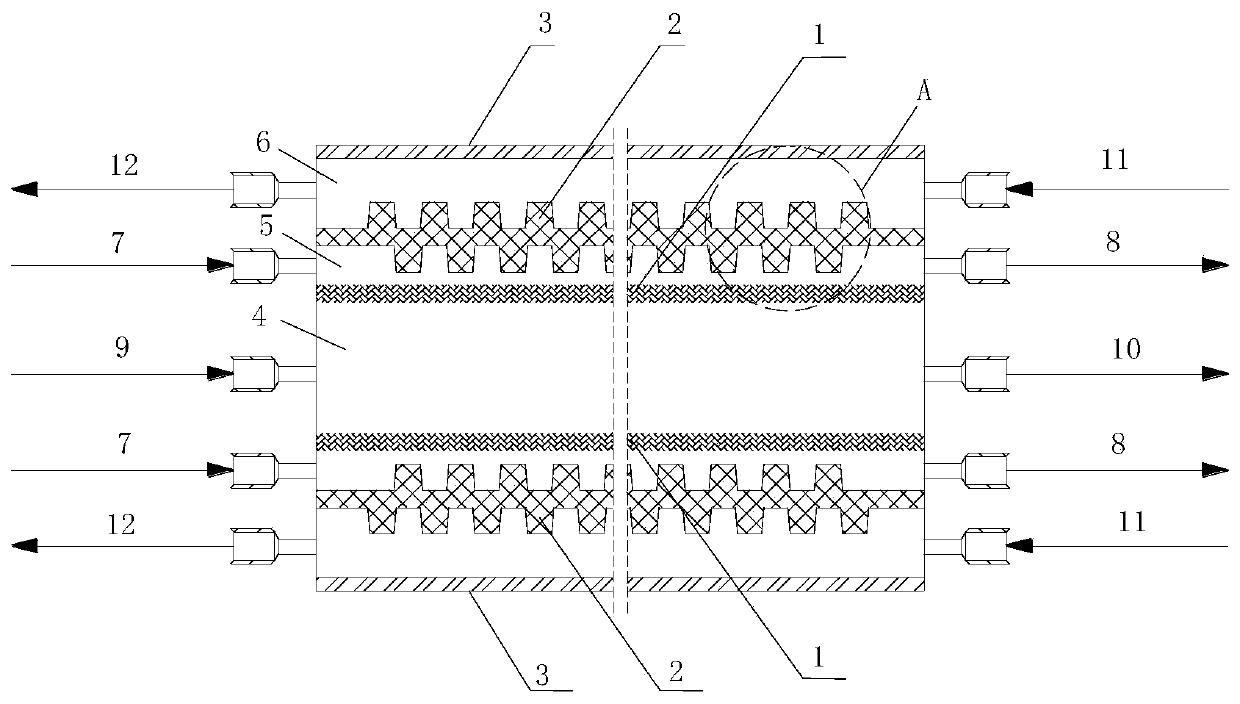

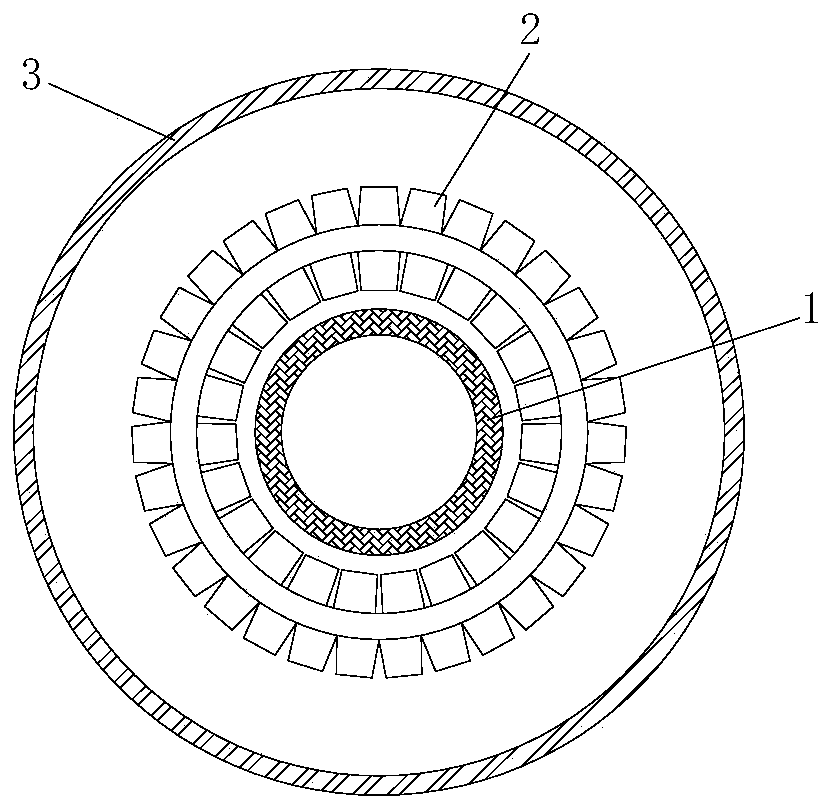

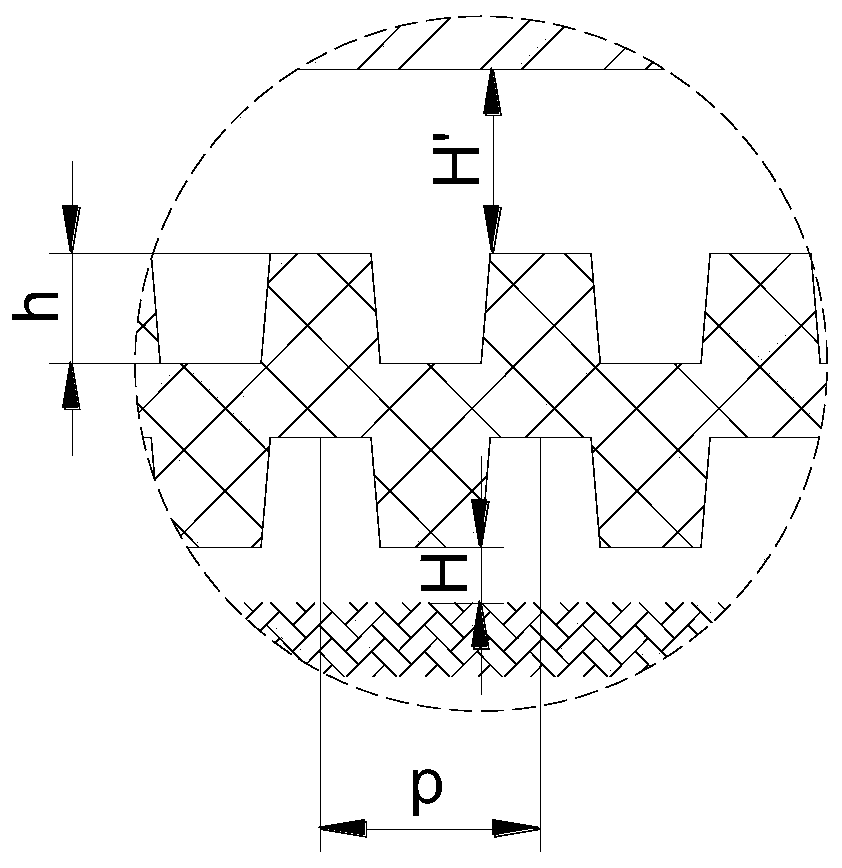

[0058] Such as Figure 1~3 As shown, the hydrogenation microreactor includes a casing reactor body, and the casing reactor body includes an inner casing 1, an...

Embodiment 2

[0071] A process for preparing phenylenediamine through micro-reaction technology, comprising the following steps: first making a suspension from nitroaromatics to be reduced, a solvent and a catalyst, and then continuously feeding the suspension into a hydrogenation micro In the reactor, hydrogen is continuously fed into the hydrogenation microreactor at the same time to carry out continuous hydrogenation reduction reaction.

[0072] The reaction solution obtained in the hydrogenation microreactor enters the hydrogenation aging device for aging, and the end point is when no nitro compounds are detected.

[0073] The nitroaromatics are a mixture of m-dinitrobenzene and o-dinitrobenzene, and the mass ratio of m-dinitrobenzene and o-dinitrobenzene is 4:1.

[0074] The mol ratio of hydrogen and m-dinitrobenzene added in the hydrogenation microreactor is 10:1; the weight ratio of feed is m-dinitrobenzene: solvent (methanol): catalyst (skeleton nickel)=1: 1.8: 0.06; Control the te...

Embodiment 3

[0078] A process for preparing phenylenediamine through micro-reaction technology, comprising the following steps: first making a suspension from nitroaromatics to be reduced, a solvent and a catalyst, and then continuously feeding the suspension into a hydrogenation micro In the reactor, hydrogen is continuously fed into the hydrogenation microreactor at the same time to carry out continuous hydrogenation reduction reaction.

[0079] The reaction solution obtained in the hydrogenation microreactor enters the hydrogenation aging device for aging, and the end point is when no nitro compounds are detected.

[0080] The nitroaromatics are a mixture of m-dinitrobenzene, p-dinitrobenzene and o-dinitrobenzene, and the mass ratio of m-dinitrobenzene, p-dinitrobenzene and o-dinitrobenzene is 5:1:2 .

[0081] The mol ratio of hydrogen and m-dinitrobenzene added in the hydrogenation microreactor is 12:1; the feed weight ratio is m-dinitrobenzene: solvent (methanol): catalyst (skeleton ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com