Novel method for preparing potassium thioacetate

A technology of potassium thioacetate and thioacetic acid, which is applied in the direction of organic chemistry, can solve problems such as low purity of potassium thioacetate, easy oxidation of air, and catalyst poisoning, so as to improve equipment use efficiency, prevent products from absorbing moisture, Reduce the effect of mother liquor residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

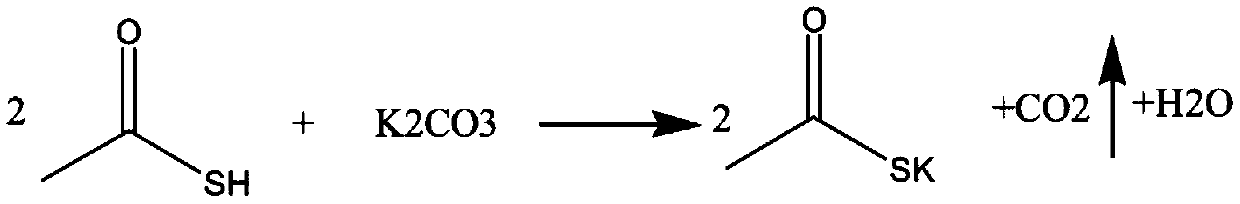

Method used

Image

Examples

Embodiment 1

[0052] (1) Turn on the tail gas absorption system, add 550kg of absolute ethanol to the 1500L jacketed glass-lined reactor, put refrigerant ice salt water into the jacket, start stirring, the speed is 50-90 rpm, add 360kg Potassium carbonate, and the temperature in the reactor is controlled at -15 to 20°C;

[0053] (2) Slowly add 400kg of thioacetic acid dropwise to the reaction kettle at a rate of 80Kg / hour; the reaction is exothermic, and the temperature of the kettle is controlled at -15 to 20°C by using jacketed ice salt water. ~20°C constant temperature reaction for 10 hours; after the constant temperature reaction, control the temperature in the reactor at -10~10°C and prepare for centrifugation;

[0054] (3) Turn on the centrifuge, make it run slowly, and flush nitrogen into the centrifuge to improve the safety factor and reduce the contact between the product and the air. Slowly put the reactants obtained in step (2) into the centrifuge In the centrifuge, the potassiu...

Embodiment 2

[0059] (1) Turn on the tail gas absorption system, add 500kg of absolute ethanol to the 1500L jacketed glass-lined reactor, put refrigerant ice salt water into the jacket, start stirring, the speed is 50-90 rpm, add 355kg Potassium carbonate, and the temperature in the reactor is controlled at -10 to 30°C;

[0060] (2) Slowly add 400kg of thioacetic acid dropwise to the reaction kettle at a rate of 80Kg / hour; the reaction is exothermic, and the temperature of the kettle is controlled at -10 to 30°C by using jacketed ice salt water. After the addition of thioacetic acid is completed, the temperature is controlled at -10 React at a constant temperature of ~30°C for 10 hours; after the constant temperature reaction is completed, control the temperature in the reactor at -10-20°C and prepare for centrifugation;

[0061] (3) Turn on the centrifuge, make it run slowly, and flush nitrogen into the centrifuge to improve the safety factor and reduce the contact between the product and ...

Embodiment 3

[0066] (1) Turn on the tail gas absorption system, add 550kg of absolute ethanol to the 1500L jacketed glass-lined reactor, put refrigerant ice salt water into the jacket, start stirring, the speed is 50-90 rpm, add 360kg Potassium carbonate, and the temperature in the reactor is controlled at 0~40°C;

[0067] (2) Slowly add 400kg of thioacetic acid dropwise to the reaction kettle, and the dropping rate is 80Kg / hour; the reaction is exothermic, and the temperature of the kettle is controlled by jacketed ice salt water at 0-40°C. After the addition of thioacetic acid is completed, the temperature is controlled at 0-40 ℃ constant temperature reaction for 10 hours; after the constant temperature reaction is completed, control the temperature in the reactor at -5 ~ 30 ℃, and prepare for centrifugation;

[0068] (3) Turn on the centrifuge, make it run slowly, and flush nitrogen into the centrifuge to improve the safety factor and reduce the contact between the product and the air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com