Dibutyltin dilaurate synthesis process

A technology of dibutyltin cinnamate and synthesis process, which is applied in tin organic compounds, compounds of elements of Group 4/14 of the periodic table, organic chemistry, etc. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

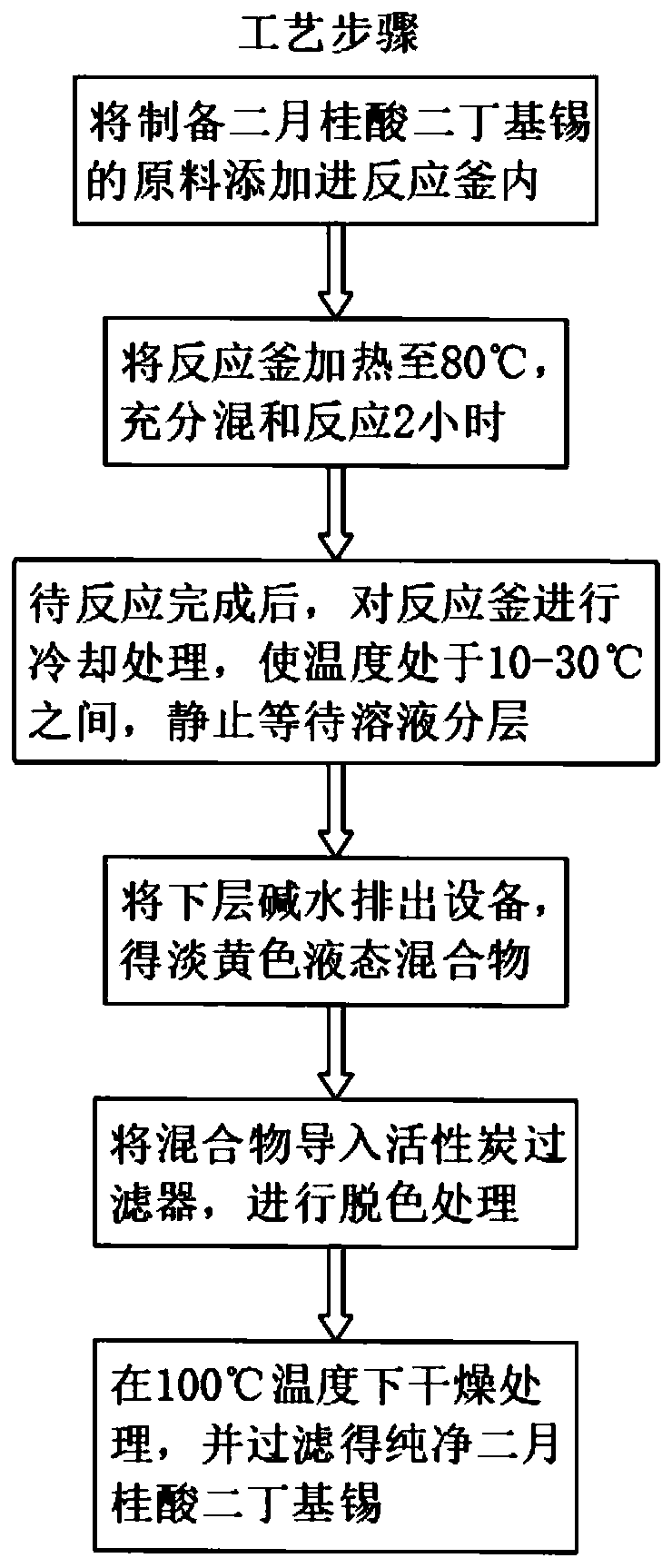

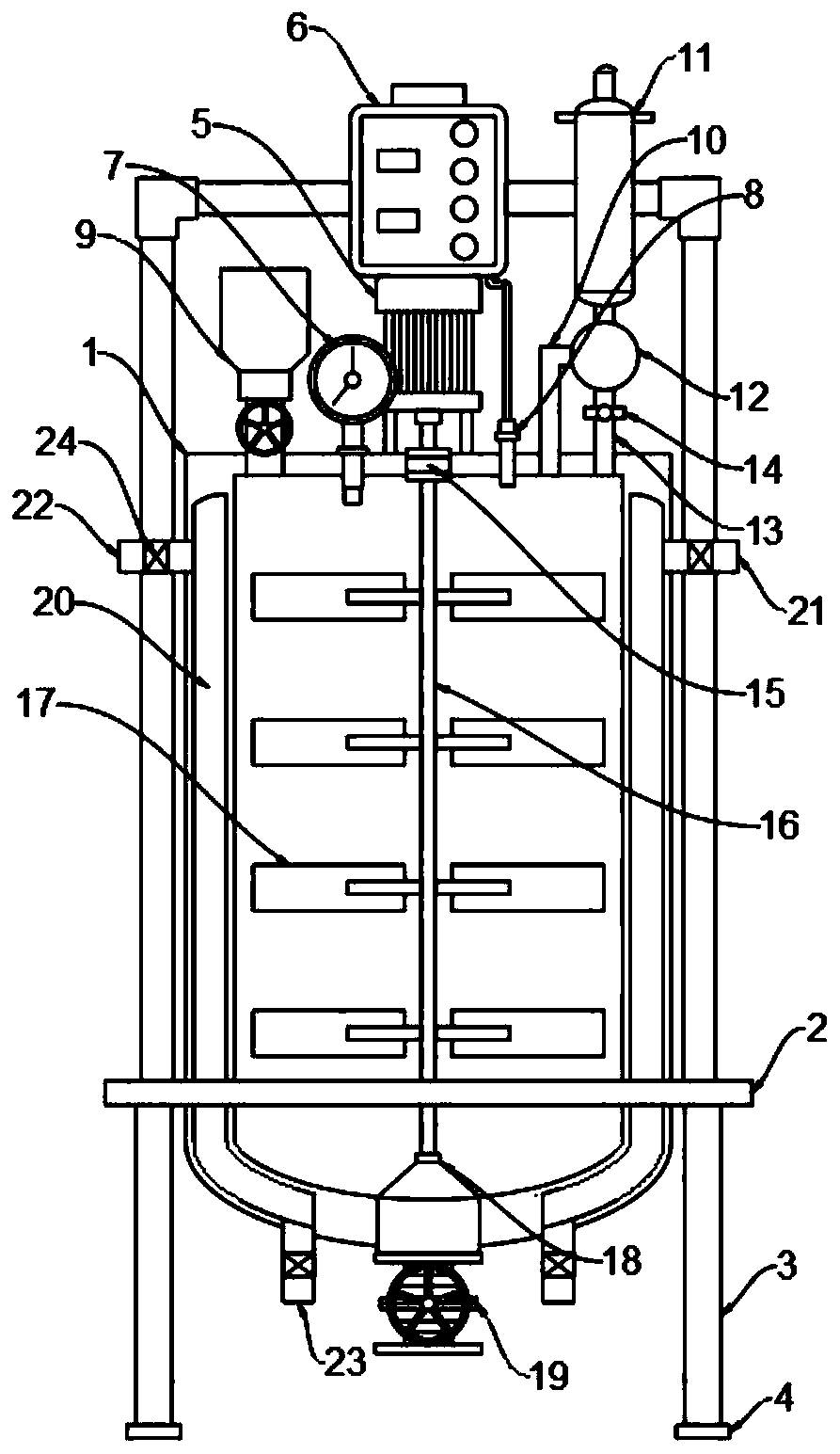

[0023] see Figure 1-2 , an embodiment provided by the present invention: a dibutyltin dilaurate synthesis process, comprising the following steps, step 1: adding the raw materials for preparing dibutyltin dilaurate into the reactor; step 2: heating the reactor to 80°C, fully mixed and reacted for 2 hours; Step 3: After the reaction is completed, cool the reactor so that the temperature is between 10-30°C, and wait for the solution to stratify; Step 4: Drain the lower layer of alkaline water from the equipment, Obtain a light yellow liquid mixture; step 5: introduce the mixture into an activated carbon filter for decolorization; step 6: dry at 100° C., and filter to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com